منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

feldspar ore grinding

11.27 Feldspar Processing - US EPA

The primary pollutant of concern that is emitted from feldspar processing is particulate matter (PM). Particulate matter is emitted by several feldspar processing operations, including crushing, grinding, screening, drying, and materials handling and transfer

获取价格

Feldspar Mining Process - JXSC Mineral

Feldspar Grinding. The crushed ore undergoes grinding to reduce the particle size further. This step is crucial for separating feldspar from other minerals and impurities. Feldspar

获取价格

Analysis Of The Fine Crystal Rock Feldspar Ore Beneficiation Process

2024年1月17日 The fine crystal rock feldspar ore beneficiation process is vital in extracting valuable minerals from raw ore. This process involves several stages,

获取价格

Systematic review of feldspar beneficiation and its comprehensive ...

2018年11月1日 In accordance with the content of impurities in the feldspar minerals and disseminated features of gangue minerals, the technology flowsheet of ore dressing of

获取价格

Study on the unequal-probability comminution of spodumene and

2023年3月15日 Abstract. The objective of this study is to establish a mathematical model to evaluate the unequal-probability comminution of minerals during the grinding

获取价格

Feldspar Mining Process Equipment Flow Cases - JXSC

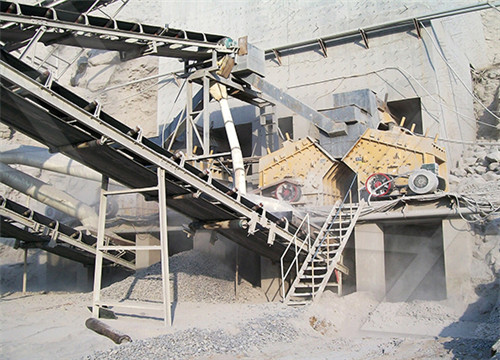

There are many options for fine crushing and grinding machines of the feldspar processing plant, mainly roller crusher, impact crusher, sand making machine,

获取价格

Dressing of Quartz-Feldspar Ores on the Basis of Selective

The possibility is shown for its effective dressing by transforming feldspars into the finer products with quartz concentration in the coarser fractions. It is established that in

获取价格

AP-42 Background Document for Section 11.27 Feldspar

for most feldspar ore beneficiation. Figure 2-1 shows a process flow diagram of the flotation process. The ore is crushed by primary and secondary crushers and ground by jaw

获取价格

Feldspar Beneficiation Flotation Process - 911 Metallurgist

2016年4月14日 Feldspar Ore Crushing. Feldspar ore is generally quarried from an open pit deposit and transported to the mill by truck. The flowsheet shows a conventional two

获取价格

Feldspar Processing Plant - JXSC Machinery

The common feldspar beneficiation flow mainly includes the following four types: High-quality feldspar produced in pegmatite: hand selection – crushing – wet grinding – classifying. Feldspar in weathered granite:

获取价格

Analysis Of The Fine Crystal Rock Feldspar Ore Beneficiation Process

2024年1月17日 The fine aplite feldspar ore crushing process is a critical step in obtaining high-quality feldspar for various applications. Several factors must be considered during this process to ensure the best results. ... Fine crystal rock feldspar ore grinding process. It mainly involves grinding equipment to crush and grind raw materials into fine powder.

获取价格

Ball Mill Mining Grinding Mill - JXSC Machinery

Introduction: The ball mill is a tumbling mill that uses steel balls as grinding media. Ball mills can be used in wet or dry systems for bulk and continuous milling, and are most widely used in small or large-scale ore beneficiation

获取价格

Feldspar Mining Process Equipment Flow Cases - JXSC

At present, feldspar grinding can be divided into dry grinding and wet grinding, wet type grinding is more efficient than dry type. ... On the one hand, it can reduce the content of Fe2O3 in feldspar ore, on the other hand, it can increase the content of potassium and sodium in feldspar ore. Common ore washing machines: Denver washer dryer ...

获取价格

A Review on Potash Recovery from Different Rock and Mineral

2020年8月31日 Amarante et al. studied the beneficiation of a Portuguese feldspar ore by magnetic separation followed by froth flotation with HF or H 2 SO 4 as the pH regulators and commercial amine acetate collectors like Armoflote 820 and 543. They found that a final feldspar concentrates with K 2 O of 13.87% could be enriched from the feed K 2 O value

获取价格

AP-42 Background Document for Section 11.27 Feldspar

for most feldspar ore beneficiation. Figure 2-1 shows a process flow diagram of the flotation process. The ore is crushed by primary and secondary crushers and ground by jaw crushers, cone crushers, and rod mills until it is reduced to less than 841 µm (20 mesh). Then the ore passes to a three-stage, acid-circuit flotation process.

获取价格

Pozzolanic activity and hydration properties of feldspar after ...

2021年5月1日 The particle size distribution curves of the feldspar powders with different grinding times were listed in Fig. 1. For the initial feldspar, the particle size distribution curve was unimodal, and the particles of > 100 μm were observed. At 10 min of grinding, the particle size distribution curve became narrow and shifted to the left.

获取价格

A comparative study on the effects of dry and wet grinding on

2019年9月1日 In a feasibility study, dry grinding of magnetite ore for particle production from 50 mm to 90 µm was performed by using HPGR. ... High intensive dry grinding of K-feldspar increases reactivity, surface area, and deforms its lattice structure, thus results in potassium recovery enhancement [37]. 3. Effects on mineral flotation3.1.

获取价格

How to Improve the Grade of Feldspar with Complex Gangue

2022年11月11日 feldspar ore. At present, the common process of feldspar beneficiation generally includes“crushing- grinding- desliming- classification- magnetic separation- flotation”. Ⅰ. Crushing and Grinding

获取价格

9 Different Minerals Used as Abrasives - ThoughtCo

2019年3月6日 The garnet mineral almandine is harder than quartz (Mohs 7.5), but its real virtue is its sharpness, giving it cutting power without scratching wood too deeply. Corundum is the workhorse abrasive of sandpaper. Extremely hard (Mohs 9) and sharp, corundum is also usefully brittle, breaking into sharp fragments that keep on cutting.

获取价格

Process mineralogy of Dalucao rare earth ore and design of

2020年6月28日 3.2 Ore sample flotation test. The grinding time, costs and total beneficiation cost increased. ... However, seen from the degree of liberation, the intergrowth of the rare earth ore and feldspar, as well as calcite, quartz, fluorite and biotite was severe. Gravity separation would lead to a low yield of rare earth, and high-grade minerals ...

获取价格

Research Status of Spodumene Flotation: A Review - Taylor

2020年6月10日 Spodumene is one of the important lithium resources, so it is of great significance to concentrate it. Beneficiation methods of spodumene include magnetic separation, gravity separation, and flotation. Since the major gangue minerals of spodumene are quartz and feldspar, flotation becomes the most important way to concentrate

获取价格

Mica Beneficiation - 911 Metallurgist

2021年1月13日 The ore, after grinding and desliming, contained about 1 percent minus 200-mesh material. The pulp then passed to a conditioner, where the reagent for pH control and quartz depression was added. ... The undersize is composed mainly of quartz, feldspar, clay, and fine mica that is removed from the circuit. The coarse particles are retained by ...

获取价格

A novel approach for flotation recovery of spodumene, mica and feldspar

2017年10月1日 By adopting the flowsheets presented in the paper, nearly 70% of raw lithium pegmatite ore is translated into qualified mica, spodumene and feldspar products to realize a comprehensive utilization ...

获取价格

Simple Ore Extraction: Choose A Wholesale silica grinding ball

limestone silica sand gold ore ball mill 3200x4500 dry wet ball grinding mill machine in philippines $255,000.00 ... Widely Used Limestone Gypsum Calcium Carbonate Quartz Silica Sand Grinding Dry Ball Mill Cement Coal Feldspar Dolomite Ball Mill $5,800.00. Min Order: 1 set. 5 yrs CN Supplier . 5.0 /5 2 reviews Contact Supplier. Chat now ...

获取价格

Research Status of Spodumene Flotation: A Review - Taylor

2020年6月10日 Spodumene is one of the important lithium resources, so it is of great significance to concentrate it. Beneficiation methods of spodumene include magnetic separation, gravity separation, and flotation. Since the major gangue minerals of spodumene are quartz and feldspar, flotation becomes the most important way to concentrate

获取价格

Mica Beneficiation - 911 Metallurgist

2021年1月13日 The ore, after grinding and desliming, contained about 1 percent minus 200-mesh material. The pulp then passed to a conditioner, where the reagent for pH control and quartz depression was added. ... The undersize is composed mainly of quartz, feldspar, clay, and fine mica that is removed from the circuit. The coarse particles are retained by ...

获取价格

A novel approach for flotation recovery of spodumene, mica and feldspar

2017年10月1日 By adopting the flowsheets presented in the paper, nearly 70% of raw lithium pegmatite ore is translated into qualified mica, spodumene and feldspar products to realize a comprehensive utilization ...

获取价格

Simple Ore Extraction: Choose A Wholesale silica grinding ball

limestone silica sand gold ore ball mill 3200x4500 dry wet ball grinding mill machine in philippines $255,000.00 ... Widely Used Limestone Gypsum Calcium Carbonate Quartz Silica Sand Grinding Dry Ball Mill Cement Coal Feldspar Dolomite Ball Mill $5,800.00. Min Order: 1 set. 5 yrs CN Supplier . 5.0 /5 2 reviews Contact Supplier. Chat now ...

获取价格

Production, Reserves, and Processing of Feldspar and ... - MDPI

2020年8月17日 This paper aims to characterize and interpret the trends in reserves, resources, and mine production of feldspar and feldspathoid rocks during 2005–2019 in the Czech Republic. With over 101 Mt of total resources and 22 Mt of reserves, feldspar belongs to the crucial industrial minerals of the Czech Republic. With annual outputs of

获取价格

Study on the unequal-probability comminution of spodumene and feldspar

2023年3月1日 Guo et al. [90] discovered that increasing grinding mill filling reduced the liberation of lithium ore. Grinding media and material were centrifuging at 60% mill filling volume whilst this ...

获取价格

Molybdenum Mining - JXSC Mineral

About Molybdenum Ore. Molybdenum (Mo) is a metallic, lead-gray element with a density of 10.2 g / cm³, with a high melting point (4,730 degrees Fahrenheit). Molybdenum occurs in nature in chemical combination with other elements. There are various molybdenum-bearing minerals, but the only one of commercial significance is molybdenite (MoS2 ...

获取价格

Feldspar Beneficiation Process Magnetic Flotation - JXSC Machine

2019年6月25日 (2) Stripping-strong magnetic separation process combined flow If the feldspar ore is soft, easy crushing, put them into the grinding mill machine to peel off the iron material in the mica group minerals. The result shows that the stripping-strong magnetic separation process has a significant improvement, besides, its cost is lower than that of ...

获取价格

Effect of calcination on coarse gangue rejection of hard rock

2022年7月28日 The results showed that the non-calcined ore required 1.73 times more energy for grinding than the calcined ore i.e. W i (i.e. BBMWI) for the non-calcined ore was 44.9 kWh/t and for the calcined ...

获取价格

Beryllium Extraction and Beneficiation - 911 Metallurgist

2016年4月12日 In general, beryl will concentrate with the feldspar flotation product. Depressing the feldspar and reflotation of the beryl into a high grade marketable concentrate (at least 8.0% BeO) is the usual procedure. GRINDING AND CLASSIFICATION. For the grinding of beryl and other non-metallic ores a Rod Mill is

获取价格

Experimental study on removal of iron from potash feldspar

crushing raw ore, then grinding and screening, so that the feldspar ore 106μm through; Ore that is below the 106μm standard sieve has to remove the mud, taking the things that are on the top of ...

获取价格

Processing Methods for 4 Common Feldspar - Mining-pedia

2019年12月23日 Before the feldspar flotation, the owner must be undressed ore chemical composition, mineral composition, ore structure, composition, density of run of mine ore, ore grade is relatively grinding degree properties are measured, such as scientific selection of experiment report recommended by single or combined feldspar mining process, to

获取价格

A novel approach for flotation recovery of spodumene, mica and feldspar ...

2018年2月10日 As shown in Table 8, when the ore is ground to 65% passing 74 μm in the first grinding process, the amount of slime and the lost Li 2 O in the mica concentrate are reduced to 1.55% and 3.01%, respectively. The workload for the second grinding process added between the roughing flotation and cleaning flotation of spodumene is greatly

获取价格

11.27 Feldspar Processing - U.S. Environmental Protection

for most feldspar ore beneficiation. Figure 11.27-1 shows a process flow diagram of the flotation process. The ore is crushed by primary and secondary crushers and ground by jaw crushers, cone crushers, and rod mills until it is reduced to less than 841 µm (20 mesh). Then the ore passes to a three-stage, acid-circuit flotation process.

获取价格