مسكن

>

dust control for impact crushers

مسكن

>

dust control for impact crushers

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

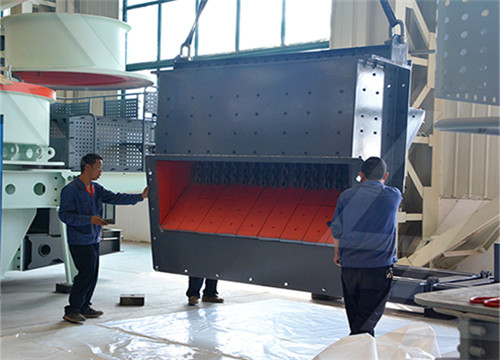

dust control for impact crushers

Dust Suppression for Crusher - H1 System, EmiControls - YouTube

观看视频0:492019年5月6日 Ever wondered how you can successfully control dust for crushing operations? We offer a custom-made versatile high-pressure misting system. More about our H1 System:...

获取价格

Engineering Controls Database - Best Practices for Dust Control in ...

Dust control for the crushing and grinding processes is normally achieved by either wet suppression or local exhaust ventilation (LEV) systems, or a combination of both.

获取价格

Improved dust capture methods for crushing plant - ScienceDirect

2007年2月1日 The fundamental design of gyratory crushers does not usually include the integration of dust control systems, which are normally retrofitted to local specification

获取价格

Crusher Plant Dust Suppression: Silica compliance Safety

Proper Crusher Dust Control: What It Needs Controlling and minimizing exposure to silica dust requires proper wet dust suppression for rock crushers. Because water has a

获取价格

Systems and products for dust suppression Maitek srl

GUIDELINES FOR THE CONTROL OF DUST AND ASSOCIATED

B. Dust control is the same treatment as for compressive crushing but another way to help cut down the dust being blown out of an impact type crusher is to cut down the quantity

获取价格

Dust Suppression Systems For Crushing Screening Plants

In crushing and screening plants, single, double fluidized water pulverization and fan sprayed dust control systems are used in The pressing of dust released in truck

获取价格

Dust emission from crushing of hard rock aggregates

2019年3月1日 Crushing generates more dust and more coarse particles compared to drilling. Local dust sources, such as hauling, have an impact on dust mass

获取价格

impact crusher dust control

Dust emission from crushing of hard rock aggregates Crushing produces mainly coarse (TSP and PM 10) dust particles which settle near the dust source The mass

获取价格

Engineering Controls Database - Best Practices for Dust

Several methods for reducing worker exposure to silica dust at crusher locations are provided below: Isolate the facility from the general mine air circuit. Dust generated from this source can be adequately contained

获取价格

I-100 I-110 I-110RS I-130 IMPACT CRUSHERS - Bell Equipment

The Finlay I-100 tracked impact crusher has been specifically designed for quarrying, recycling and demolition applications. The I-100 features a Ø860mm x 860mm (Ø34” x 34”) direct drive impact chamber with variable rotor speed. The advanced electronic control system monitors, controls and regulates the

获取价格

McLanahan Impact Crushers - Primary

Impact Crushers - Primary. ... and lower adjustable screen gate for precise product control with maximum output. In many cases, the primary breaker is able to produce 75% minus 1-1/2”. This means 75% of the feed is already product for most base plants, ... while also keeping dust to a minimum.

获取价格

Rock crushing Wisconsin DNR

Review the video Pardon My Dust [Video], the training PowerPoint (AM-622) and and the example fugitive dust plan (SB-138). To know how much of an additive is allowed in water for dust prevention, refer to the storm water standards for Water quality review procedures for additives , and the two companion documents: Allowable usage rates for water applied

获取价格

11.19.2 Crushed Stone Processing and Pulverized Mineral Processing

secondary crushing (although impact crushers are sometimes used), which typically reduces material to about 2.5 to 10 centimeters (1 to 4 inches). The material (throughs) ... for which emissions are amenable to capture and subsequent control. Fugitive dust sources generally involve the reentrainment of settled dust by wind or machine movement.

获取价格

Engineering Controls Database - Best Practices for Dust Control

The dust-laden air is then directed to a nearby return, a bag house, or a fan-powered dust collector where it is captured by filters and the clean air can be discharged into the mine air [NIOSH 2003a]. Figure 2 shows a conceptual approach to control crusher dust in a stone mine using a closed ventilation system. Figure 2 - .

获取价格

Crushing Plant Design and Layout Considerations - 911 Metallurgist

• Electronic control of crusher discharge opening and feed rate. With adjustment of a crusher’s discharge opening, as the production continues through an on-line coarse size analysis of the crushed product (digital image analyses). Dance, A. 2001) • More attention is being paid to the impact on crushing circuit design caused by variations

获取价格

Crusher - an overview ScienceDirect Topics

The impact crusher (Fig. 13.15 ... Srikanth [7] used a jaw crusher to create −37 μm coal dust particles. ... In some cases, like the control of a crusher operation, a constant term has to be introduced in Eq. (18.67) as at zero control

获取价格

CRUSHES PERFECT PRODUCT SQUEEZES YOUR COSTS - SRP

SANDVIK VERTICAL SHAFT IMPACT CRUSHER RANGE. 2 VERTICAL SHAFT IMPACT CRUSHER. ROCKTECHNOLOGY.SANDVIK 3 SHAPING A ... Minimizes dust emissions at low or no feed, and by dry and dusty material ELECTRICAL CONTROL PANEL Ensures correct starting and electrical control of crushers HIGH TEMPERATURE BEARING

获取价格

11.19.1 Sand And Gravel Processing - US EPA

Gyratory crushers, jaw crushers, roll crushers, and impact mills are used for primary and secondary crushing. After crushing, the size of the material is further reduced to 50 micrometers ( m ... In addition to fugitive dust control techniques, some facilities use add-on control devices to reduce emissions of PM and PM-10 from sand and gravel ...

获取价格

What Are the Pros Cons of Impact Crushers? Mormak

However, what are the pros and cons of impact crushers why should you choose one? Find out! 1.844.MORMAK1 (667.6251) 1.844.MORMAK1 (667.6251) Make A Payment. Navigation. ... which can be an occupational health and safety concern if not mitigated through the implementation of dust control measures. For impact crushers to suit your

获取价格

(PDF) Environmental health assessment of stone crushers in

2011年3月23日 Abstract: The mining and stone crushing activities have considerable effects on the environment quality and human health. The dust emissions contaminate the air and water. Investigations made on ...

获取价格

How to Control the Discharge Size in Crushing

2023年2月15日 The customers need to control the stones or sand in a certain finished particle size, so it is necessary to know how to control the sizes with various crushers. ... The following is a detailed description of

获取价格

Stationary VSI impact crushers, Sandvik VSI Crusher Brochure

Choosing a Sandvik VSI crusher ensures you get reliability every time and the support to help when you need it. CV200 VSI crusher series - Operational flexibility. In the aggregate, mining, and quarrying sectors, Sandvik VSI impact crushers are used for the production of high-quality manufactured sand and premium shaped aggregates.

获取价格

SANDVIK CV200 RANGE VERTICAL SHAFT IMPACT CRUSHERS (VSI)

IMPACT CRUSHERS (VSI) CV200 RANGE VSI CRUSHER - OPERATIONAL FLEXIBILITY Sandvik Stationary VSI impact crushers are designed for higher capacity, reduced power consumption, reduced maintenance costs and intervals. In the aggregate, mining and quarrying sectors, Sandvik VSI impact crushers are used for production

获取价格

Recycled material crushing with high reduction ratio - Metso

Lokotrack LT1213 mobile horizontal impact crusher (HSI) combines mobility, high capacity and versatility. It is suitable for a various applications such as limestone processing and recycled materials crushing. IC process control for connectivity Radio remote for feeder control and tracking ICr Connection between multiple units

获取价格

About - ABCDust - #1 The best dust control solution

Our company offer comprehensive service solutions to control and monitor the Particulate Material (MP) to control dust emission from unpaved roads, crushers, stockpiles and other industrial process. Our solutions reduce dust control costs and infrastructure maintenance costs; optimizing the use of water and additives under the highest standards of safety,

获取价格

Mobile jaw crushers for impact crushing - Wirtgen

Mobile impact crushers. The mobile MOBIREX impact crushers are used in soft to medium-hard natural stone and in recycling. The performance of the plants is impressive – not just in terms of pure volume reduction. The focus today is on cost and environmental awareness, availability, versatility and, above all, the quality of the end-product to ...

获取价格

How do you control dust in a crushing plant?

2022年5月5日 Crusher dust is a type of fine dust, which contains very small 0-5mm aggregate particles as well as sand. It is formed as a by-product from mining operations and is often recycled for different applications such as construction. ... Impact of Dust Control on Canadian and U.S. Mining.

获取价格

Understanding Effects of Crushing Mechanism on Aggregate Morphology ...

2019年10月25日 In the present study, the effects of two different crushing operations (jaw-cone-vertical shaft impact (VSI): JCV and jaw-horizontal shaft impact (HSI): JH) on coarse aggregate morphology were studied. Angularity, texture, sphericity and FE of three different sizes of coarse aggregates: passing a sieve of 19 mm and retaining a sieve of 12.5 mm ...

获取价格

Company A-Z - Mining Technology

Dust Control, Erosion Control, Water Management and Soil Stabilisation Solutions for the Mining Sector. Global Tech Group. ... Design and Manufacture of Jaw Crushers, Impact Crushers and Portable Crushing Plants. LIQUI MOLY. Engine-Enhancing Additives for Mining Operations. Litesource. Washroom and LED Lighting Equipment.

获取价格