منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

grinding mica crushing

Items You Must Know about Mica Grinding: Methods and Machines

Crushing of Mica Ore - 911 Metallurgist

Pneumatic Concentration MethodsEquipment and MethodMethods of AnalysisExperimental ResultsArizona mica-bearing PegmatiteJaw CrusherRoll CrusherDescription A sample obtained from an Arizona mica-bearing pegmatite contained approximately 22 percent mica. The sample was split into three fractions to study the relative effects of the three types of crushers. Several mica sheets up to about 1.5 square inches of surface area were found in the sample, but most of the mica grains were smaller tha...data-id="" >Mining-pedia

Mica Industrial Grinding Mill - SBM Ultrafine Powder Technology

2021年7月30日 Mica crushing and grinding process. The Mohs hardness of mica ore is 2~3. It can be ground into fine powder by a mica industrial grinding mill. The main mica

获取价格

Mica Beneficiation - 911 Metallurgist

2021年1月13日 Most flake mica is obtained as the major marketable product by crushing and milling pegmatites. To a lesser extent, mica is produced as a byproduct of feldspar and spodumene. ... and grinding mica, and information on the production, uses, and prices of mica. Part 1.—Mica Process Development Description of Ores.

获取价格

Crushing and grinding plant for mica mining operation in India

Grinding is after crushing operation in mica mining process. It is an essential step inmica processing. Different types of mill are applied in milling operation, such as ball mills, vertical roller mill, Raymond mill, ultrafine mill etc.

获取价格

Mica Industrial Grinding Mill - SBM Ultrafine Powder Technology

2021年7月30日 Mica crushing and grinding process. The Mohs hardness of mica ore is 2~3. It can be ground into fine powder by a mica industrial grinding mill. The main mica powder meshes are 325 mesh, 400 mesh, 800 mesh, 1250 mesh, 2000 mesh, and 3000 mesh, as well as superfine mica powder.

获取价格

Crushing of Mica Ore - 911 Metallurgist

2017年8月5日 Crushing of mica prior to pneumatic processing technique were studied for concentrating coarse mica. Muscovite and phlogophite are the two major commercial mica minerals. However, this research was conducted exclusively with muscovite, and throughout this paper mica will mean muscovite. ... Crushing and grinding of the ore is limited to

获取价格

Lithium deportment by size of a calcined spodumene ore

2022年10月31日 The crystal lattice parameters in mica increase at a temperature in the range of 650 °C, ... Bond, F. C. Crushing and grinding calculations. Br. Chem. Eng. Part I 6(6), 378–385 (1961).

获取价格

How to Crush Rocks at Home – The Home Answer

2023年1月27日 Hammering One of the quickest and easiest ways to crush rocks into powder is by using a hammer. Simply strike the rock with a heavy object – like a hammer or a piece of concrete – and it will break up into smaller pieces. You can then use a sieve to separate the powder from any larger pieces. Grinding Another common method is to

获取价格

Feldspar Beneficiation Flotation Process - 911 Metallurgist

2016年4月14日 Closed circuit crushing is advisable in larger tonnage operations for maximum grinding efficiency and capacity. Feldspar Ore Grinding. The Rod Mill is standard for grinding feldspar ore, producing a granular product with a minimum of slime and fine size material. Grinding is always done to minus 20 mesh on account of market

获取价格

crushing and grinding machines mica Mining Quarry Plant

Ball mill could be the coarse grinding machine within the mica powder productin line and is an efficient tool for grinding many materials into fine powder. Get price and support, find the working site in your country ! Please enter your demand such as production capacity, feeding material size, final product size.

获取价格

Processing Spodumene by Froth Flotation for Lithium Extraction

2016年5月9日 Since this method is selective for the separation of mica, feldspar, and quartz, it solves the problem of marketing all possible products. ... Two stage, open circuit crushing is satisfactory in the 200 ton per 8 hour production range. The resulting fine ore is smaller than ½” or ¾”. ... Grinding and Classification.

获取价格

KR100493212B1 - Method for processing a mica - Google Patents

A method of processing mica is disclosed, which processes mica that emits far infrared rays and promotes blood circulation and growth for use in paints, clothing, cosmetics, and pharmaceuticals. In the mica processing method according to the present invention, first, high-quality mica is prepared. After drying the mica so that there is no moisture, it is first

获取价格

Quartz Industrial Powder Grinder Machine - SBM Ultrafine

2021年10月11日 2 Quartz crushing and grinding process: 3 Introduction of Quartz Industrial powder grinder: 3.1 HGM ultrafine grinding mill; ... In addition to grinding quartz, they can also grind other non-metallic ores such as dolomite, calcium carbonate, mica, calcite, kaolin, etc. They are widely used, have good grinding effects, and are highly

获取价格

The Beginner's Guide to Mica Processing Mining Pedia

2023年4月17日 The processing of mica for separation is complex and usually requires a number of process steps such as grinding, flotation, desliming and iron removal. During the grinding process, the raw minerals need to be crushed into smaller particles for the subsequent flotation process. In the flotation process, the mica and other impurity

获取价格

How the Nano Milling Process Works Blog - Hockmeyer

2021年12月27日 These particles are invisible to the naked human eye, and thanks to their submicroscopic size, they have unique characteristics applicable to a variety of applications in a wide range of industries. The process of nano milling, or nano grinding, is the reduction of particles down to a very fine consistency through the use of wet grinding media ...

获取价格

how to grind mica powder - LinkedIn

2023年7月27日 Prepare the Mica Flakes: If your mica is in the form of large flakes or sheets, break them down into smaller pieces to facilitate the grinding process. You can use a mortar and pestle or any other ...

获取价格

Quartz Industrial Powder Grinder Machine - SBM Ultrafine

2021年10月11日 2 Quartz crushing and grinding process: 3 Introduction of Quartz Industrial powder grinder: 3.1 HGM ultrafine grinding mill; ... In addition to grinding quartz, they can also grind other non-metallic ores such as dolomite, calcium carbonate, mica, calcite, kaolin, etc. They are widely used, have good grinding effects, and are highly

获取价格

The Beginner's Guide to Mica Processing Mining Pedia

2023年4月17日 The processing of mica for separation is complex and usually requires a number of process steps such as grinding, flotation, desliming and iron removal. During the grinding process, the raw

获取价格

How the Nano Milling Process Works Blog

2021年12月27日 These particles are invisible to the naked human eye, and thanks to their submicroscopic size, they have unique characteristics applicable to a variety of applications in a wide range of industries. The

获取价格

how to grind mica powder - LinkedIn

2023年7月27日 Prepare the Mica Flakes: If your mica is in the form of large flakes or sheets, break them down into smaller pieces to facilitate the grinding process. You can use a mortar and pestle or any other ...

获取价格

Limestone Ultrafine Mill Machine - SBM Ultrafine Powder

2021年9月13日 The limestone ultrafine mill machine is a highly efficient industrial grinding mill. It can grind limestone into a fine powder (150-3000 mesh), and the fineness can be adjusted freely. In addition, it can also grind 100+ kinds of non-metallic minerals with Mohs hardness less than 6, such as calcium carbonate, talc, calcite, carbon black,

获取价格

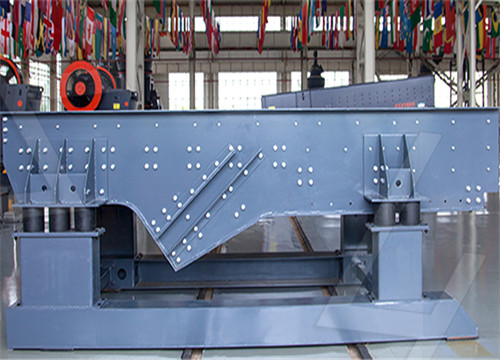

Coarse Powder Grinding Mill - SBM Ultrafine Powder Technology

Brief Introduction of Coarse Powder Grinding Mill. Coarse Powder Grinding Mill is engaging in crushing various rocks and stones with comprehensive strength not higher than 320 MPA into coarse powder and small particles. It is widely used in metallurgy, mining, chemical, cement, coal, sand-making, construction, refractory materials, and ceramic ...

获取价格

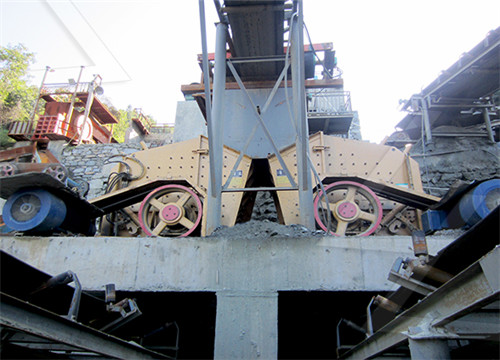

how to grind mica powder?edge runner for mica grinding china

Hammer crusher is another widely used mica crushing machine. It can crush mica into mica flake less than 15 mm. Ball mill is the most common mica mill machine. The finished size is 0.074-0.4mm, and the capacity of ball mill is 1-30 ton/p. Raymond mill is also the common mica mill used in mica beneficiation plant. It’s fineness can be upto 0 ...

获取价格

Mica Powder Uses: What You Should Know - Gravel Mill

Dry ground mica powder is made by crushing, grinding, and classifying scrap and flake mica. Wet mica powder is processed through multiple processes with water as the medium. Mica is a hard-to-grind mineral (Bond work index 148). It remains platy particles even after milling to an ultra-fine powder. When designing the wet grinding process and ...

获取价格

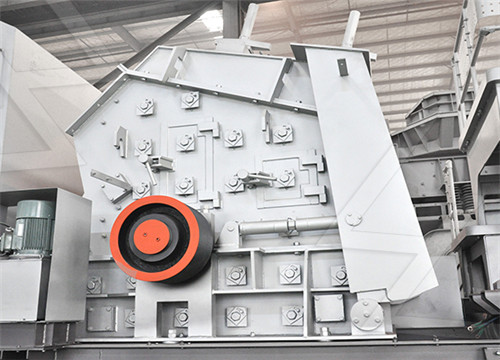

Limestone crushing technology and equipment - sbmmill

2023年12月8日 Coarse crushing equipment: The commonly used equipment is jaw crusher. In the limestone crushing production line, the coarse crushing equipment can crush the large pieces of limestone mined into stones of 125-400mm in size. Medium crushing equipment: Commonly used equipment are impact crushers, fine crushers, etc.

获取价格

Dolomite Grinding Mill - SBM Ultrafine Powder Technology

2021年7月28日 Dolomite crushing and grinding process. To obtain dolomite powder, the dolomite ore is processed through beneficiation, coarse crushing, medium crushing, powder grinding, grading, and packaging. 1. Crushing stage: Large pieces of material are crushed by the crusher to the fineness (15 mm-50 mm) that can enter the mill. 2.

获取价格

What are some common issues with Complete Mica Grinding Mill

2023年8月23日 Complete Mica Grinding Mill can face a variety of issues due to wear and tear, mechanical failures, electrical problems, and other factors. ... Aggregate Crushing Plant And Processing Jun 2, 2023

获取价格

Curious about Wollastonite Processing? Find Your Best Fit!

1 FTM Machinery engineers adopted the crushing, grinding, beneficiation, and drying method, achieving a high-quality product meeting market specifications. Stage 1: Wollastonite Crushing The mined wollastonite ore undergoes primary crushing to 100-120 millimeters using a jaw crusher , followed by secondary crushing to 30-40 millimeters by

获取价格

11.27 Feldspar Processing - US EPA

An amine collector that floats off and removes mica is used in the first flotation step. Also, sulfuric acid, pine oil, and fuel oil are added. ... Particulate matter emissions from crushing and grinding generally are controlled by fabric filters. Table 11.27-1 presents controlled emission factors for filterable PM from the drying process. Table

获取价格

How to remove mica in sand and stone? - LinkedIn

2022年1月14日 Mica minerals are still flake after crushing machine and grinding machine, while other minerals are irregular granular. Screening is carried out with the help of the shape difference of crushing ...

获取价格