مسكن

>

Wrapper Roll Hot Strip Mills Switzerland

مسكن

>

Wrapper Roll Hot Strip Mills Switzerland

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

Wrapper Roll Hot Strip Mills Switzerland

Roll cooling systems - GRIP ENGINEERING

Non-ferrous metal rolling mills. Areas of Application. Optimal solutions for Cold rolling mills Hot rolling mills. For installation in Tandem plants One-way plants Reversing plants. for roll and strip cooling.

获取价格

Hot strip mills - Cronite Group

Hot Rolling Mills Solutions Nidec Industrial Solutions

Our solutions cover all types of hot strip and plate mills for flat products including: Conventional Hot Strip Mills, Compact Strip Production plants, 1-stand and 2-stand Steckel Mills, 1-stand and 2-stand Plate Mills.

获取价格

Wrapper Roll Control System of Hot Strip Mill SpringerLink

Abstract. Wrapper roll is one of the most important components in rolling coiler. And it has great relation to the quality of the final products. Based on the programming and

获取价格

Research area Hot Strip Rolling – Automation Control Institute

Research FocusDescriptionLinksIn the research area Hot Strip Rolling, advanced nonlinear process control problems associated with the operation of a tandem hot-strip finishing mill are solved. A tandem hot-strip mill like the one shown in Fig. 2 is a nonlinear MIMO dynamical system. Its behavior is characterized by input, state, and time constraints, time variance, uncertaintie...

Aluminum Hot Rolling Mill Solutions - Primetals

Aluminum Hot Rolling Mills - Advanced technology for high-quality products. Primetals Technologies' aluminum hot rolling mill portfolio and experience comprises: Single and Two-Stand Roughing Mills; Twin Coiler Reversing

获取价格

Coiling Simulation and Control Method for Hot Strip Downcoiler

2006年9月1日 Abstract. Downcoiler is one of the major facilities in hot strip mill operation. The key to good coiling is having good equipment, modem control systems, excellent

获取价格

THE NEW GLOBAL COMPETENCE IN HOT ROLLING - Primetals

the hot strip mill for SAIL RSP in Rourkela (India) are two examples of full turn-key projects. In these projects the scope of Primetals Technologies includes civil works, bays, steel

获取价格

Modern materials for cast rolls of hot strip mills - ResearchGate

V. Goryany, O. Myronova Modern materials for cast rolls of hot strip mills ZASTITA MATERIJALA 63 (2022) broj 3 301 forces and a low rolling speed, which leads to a

获取价格

Hot Strip Mill and Cold Rolling Mill Industry

Hot rolling. This process stretches a slab into a strip. The slab is reheated to approximately 1250°C and rolled in hot conditions. The resultant strip steel is wound into a roll like toilet paper (hot coil). Chains for lifting;

获取价格

Pinch Rolls - Xtek, Inc.

1 Based on a 2001 survey of 40 worldwide hot strip steel mills. Two grades of the material are used in the pinch roll application. The grades are both hypoeutectic alloy gray cast irons, quenched and tempered to the range of 60-70 HSC. The standard material is alloyed with nickel, chromium, and molybdenum.

获取价格

Designing of Hot Strip Rolling Mill Control System

terface through the console. The second stage, when the strip tail through the last finishing mill and signal from 1 to 0, the speed of mandrel equals the speed of strip which switch from tension control to speed control, the speed of the hot run out table, pinch roll and wrapper roll is less than the speed of strip, the value of lag rate is

获取价格

Development of Modern Hot Strip mill and its Main Features

2013年12月22日 This immense power gives the hot rolling and processing facility the capability and versatility to process and roll the broadest ranges of specialty metals in the industry. The finishing mill is normally designed with six to seven 4-high mill stands, each equipped with 10 MW drives and a mill-stand load of up to 55 MN.

获取价格

Hot Strip Mill - an overview ScienceDirect Topics

Roll Design1. John G. Lenard, in Primer on Flat Rolling (Second Edition), 2014 3.5 Friction and Wear. Work rolls in hot strip mills wear due to friction between the roll surface and hot strip. (Back-up rolls wear as well, but under pressure with elastic deformation, the friction is much less, except for the high work roll roughness in the last stand of a sheet

获取价格

hot strip mill - YouTube

观看视频4:492017年12月28日 The market of rebar and wire rod is going to be saturated in few years, the spring of hot rolled coil, cold rolled coil, galvanized coil, color coated coil a...

获取价格

SMS make HSM Mill - Ecoseal

SMS make Hot Strip Mill (HSM) Spareage provides complete sealing solution for SMS make Hot Strip Mill (HSM) for different applications in Roughing mill, Finishing Mill, Pickling line etc. Spareage seals are used in different equipments in HSM like Roll Chocks, Hydraulic cylinders, Pneumatic Cylinders, Gear Boxes, Motors, Valves and other major ...

获取价格

Customers - Products - Hot-Rolled Coil - ussteel

U. S. Steel hot-rolled pickled temper rolled sheet is furnished as a mill edge coil that is pickled, temper rolled, oiled and cropped back to gauge. Pickling is the process of removing scale from the hot rolled sheet surface by the action of water solutions and inorganic acids. Options available to our customers include the ability to specify this product as dry and/or

获取价格

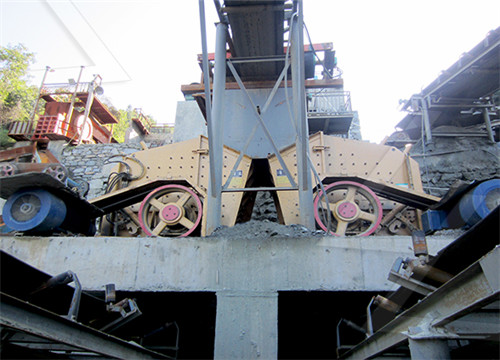

Rolls for HSM - Cronite Group

Rolls for HSM - Cronite Group. Run out table rolls, looper rolls, pinch and wrapper rolls for Hot Strip Mills. Transfer rolls and plate mill rolls for flat products. Hot transfer table rolls for flat rolling mills. Exit run out table roll. Looper roll.

获取价格

A downcoiler simulator for high performance coiling in hot strip mill ...

2009年7月23日 The objective of this study is to develop a coiling process simulator that can be used to test suggested coiling control algorithms, and thereby improve overall coiling performance. To accomplish this, a thorough study of the pinching and coiling mechanism of the downcoiler has been carried out, and then used to derive an appropriate

获取价格

Manufacture of coiler mandrel number 400 - SMS group GmbH

Hot strip mill downcoiler An essential milestone in this development work is the patented X-Roll ® coiler mandrel of closed-type design. In recent years, SMS group has already manufactured 77 of these mandrels, which are designed for coiling API-X80 pipe steel with strip thicknesses of up to 25.4 millimeters and again feature extended service ...

获取价格

The Effects of High-Speed Steel Roll and Lubrication on Work

2020年2月5日 Work rolls in the hot strip mill withstand extreme service conditions, especially when electrical steels are rolled, resulting in severe roll wear and fatigue. High-speed steel (HSS) work rolls and rolling lubrication are applied to the mill to improve roll wear and fatigue. Tests show that HSS work rolls manifest good performance in wear,

获取价格

Hot-Strip Mill at Usiminas: Superior Mill Performance - Metals

2016年1月1日 The No. 2 Hot-Strip Mill at Usiminas is one of the most modern rolling facilities of its type anywhere in the world. It is equipped with Pair Cross rolling technology and the MSD solution. Primetals Technologies supplied the complete rolling line, which included the foundation design and auxiliary equipment that comprised roll-shop

获取价格

Sun Hau Industrial Co., Ltd. = Plant Revamping Optimization/

Hot Strip Mill: Downcoiler Wrapper Rolls: USA: SMS SIEMAG for LISCO: Hot Strip Mill: Downcoiler machine: ... Hot Strip Mill: Rotary Piercing Mill thrust block: USA: TECHNINT for Rio Tinto Alcan: Hot Strip Mill: Downcoiler machine: SWITZERLAND: THYSSENKRUPP MARCINELLE: Hot Strip Mill: Operation Spare parts: BELGIUM: THYSSENKRUPP

获取价格

Automation and Thickness Control in Hot Strip Mill – IspatGuru

2020年10月16日 Fig 1 Structure of a typical automation system for hot strip mill process. Level 0 – It is the lowest level of control and includes, for example, the control loops for hydraulic capsules used to position the rolls in the rolling mills and for the main electric motors powering the mill.. Level 1 – It is primarily concerned with in-piece control. At this

获取价格

The Effects of High-Speed Steel Roll and Lubrication on Work

2020年2月5日 Work rolls in the hot strip mill withstand extreme service conditions, especially when electrical steels are rolled, resulting in severe roll wear and fatigue. High-speed steel (HSS) work rolls and rolling lubrication are applied to the mill to improve roll wear and fatigue. Tests show that HSS work rolls manifest good performance in wear,

获取价格

Hot-Strip Mill at Usiminas: Superior Mill Performance

2016年1月1日 The No. 2 Hot-Strip Mill at Usiminas is one of the most modern rolling facilities of its type anywhere in the world. It is equipped with Pair Cross rolling technology and the MSD solution. Primetals

获取价格

Sun Hau Industrial Co., Ltd. = Plant Revamping

Hot Strip Mill: Downcoiler Wrapper Rolls: USA: SMS SIEMAG for LISCO: Hot Strip Mill: Downcoiler machine: ... Hot Strip Mill: Rotary Piercing Mill thrust block: USA: TECHNINT for Rio Tinto Alcan: Hot Strip Mill:

获取价格

Automation and Thickness Control in Hot Strip Mill – IspatGuru

2020年10月16日 Fig 1 Structure of a typical automation system for hot strip mill process. Level 0 – It is the lowest level of control and includes, for example, the control loops for hydraulic capsules used to position the rolls in the rolling mills and for the main electric motors powering the mill.. Level 1 – It is primarily concerned with in-piece control. At this

获取价格

Hot Rolling Mills Solutions Nidec Industrial Solutions

Our solutions cover all types of hot strip and plate mills for flat products including: Conventional Hot Strip Mills, Compact Strip Production plants, 1-stand and 2-stand Steckel Mills, 1-stand and 2-stand Plate Mills. ... Down Coiler control (tension control, pinch roll control, wrapper roll and jumping control) Hot and cold leveler control ...

获取价格

Designing of Hot Strip Rolling Mill Control System

terface through the console. The second stage, when the strip tail through the last finishing mill and signal from 1 to 0, the speed of mandrel equals the speed of strip which switch from tension control to speed control, the speed of the hot run out table, pinch roll and wrapper roll is less than the speed of strip, the value of lag rate is

获取价格

Principles of Hot Rolling - AIST

FINISHING MILL Back-Up Roll (Undriven) Work Roll (Driven) Looper (Interstand Tension Control) Entry Side Guide (Strip Centering in Roll Bite) 0.125” 0.094” (24.8%) 0.080” (14.9%) 650 fpm 890 fpm 1380 fpm Making, Shaping and Treating of Steel: 101 Mill Configuration FINISHING MILL Work Rolls Back-Up Roll FM Stand 39 40

获取价格

(PDF) Influence of Work Hardening on the Surface of Backup Rolls

2022年5月13日 CVC (Continuous Variable Crown) work roll contour technology since its invention has been applied in more than 150 hot rolling mills worldwide for controlling strip shape.

获取价格

Hot strip mill for steel - SMS group GmbH

The X-Roll® hot strip mill from SMS group is an all-round talent in hot strip production. It is the proper solution for ultra-thin gauges up to thick gauges for all steel grades incl. LC, ULC, high strength grades, API grades. ... A compact hot strip mill comes with reasonable invest and provides the opportunity to grow flexibly with market ...

获取价格

2021 AIST North American Hot Strip Mill Roundup

2021 AIST North American Hot Strip Mill Roundup Roundup data is based on information submitted in the second quarter of 2021. Company and location Start-up/ modernization Mill builder ... 2 wrapper rolls 14.3/20.5 Direct Strip Production Complex Sault Ste. Marie, Ont. 1997 Danieli United/Siemens 1,600/ 1,346 2.00 76–84 x 29.2 Flexible thin ...

获取价格

Metals Free Full-Text Research on Strip Profile Control ...

2023年2月24日 Taking the quintic CVC technology in a 1500 mm continuous hot rolling mill production line as the research object, an integrated finite element model of rolls-strip was established by ABAQUS 2020 shown in Table 1 and Figure 4. In the actual rolling process, the bearing roll gap of the rolling mill is influenced by many factors such as

获取价格

Pinch Rolls Xtek, Inc.

Many hot strip steel mills around the world are realizing the benefits of the Xtek Bemcalloy™ Pinch Rolls.The inherent lubrication property of the graphitic constituent in the Bemcalloy™ material, along with the natural resistance to adhesion of dissimilar metals, is the basis of the pickup resistance of the material.

获取价格

A downcoiler simulator for high performance coiling in hot strip mill ...

2009年4月1日 Kawasaki Steel was the first in the world to start the so-called 'endless hot strip rolling' at the No. 3 Hot Strip Mill in Chiba Works by realizing hot sheet bar joining and continuous finishing ...

获取价格

Hot rolling mills for aluminum - SMS group GmbH

Casting and rolling of aluminium strips in one continuous production process. The new Nexcast minimill produces strips of all kinds of aluminum and aluminum alloys, with sufficient surface quality for most applications, good to very good thickness-, profile- and flatness tolerances and very stable final rolling temperature over the strip body length.

获取价格