مسكن

>

grinding ball classification machines

مسكن

>

grinding ball classification machines

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

grinding ball classification machines

(PDF) Modern grinding balls sorting machines

2019年10月1日 The paper presents major problems associated with the grinding balls sorting process, a comparison of modern types of grinding balls sorting machines, a description of their construction...

获取价格

How Grinding Balls Sorting Machines Revolutionize Material

2023年8月24日 The use of grinding balls sorting machines guarantees a higher level of quality and consistency in material processing. These machines accurately classify

获取价格

进一步探索

grinding ball sorting machine - YouTubeModern grinding balls sorting machines - Sciendo

CSM Classifier Mill - NETZSCH Grinding Dispersing

The CSM classifier mill combines a mechanical impact mill with an integrated dynamic air classifier. The grinding is performed between a peripheral grinding track and the

获取价格

进一步探索

CONDUX Classifier Mill CSM - YouTubeCONDUX Classifier Mill CSM - UL Prospector

Grinding Classification Equipment - JXSC Machinery

2020年7月7日 Grinding classification equipment is the key equipment for crushing materials after they are crushed. The ball mill can process various grinding minerals, non-ferrous metal beneficiation, and new

获取价格

A Review of the Grinding Media in Ball Mills for Mineral

2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles. Grinding media play an important role in the comminution of mineral ores in these mills. This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the mass

获取价格

Grinding Machines: Types and Selection Principles

2020年9月22日 Grinding machine has been widely used in gold mines in South Africa since 1905. At that time, the grinding machine used river pebble as the grinding medium, which was essentially a gravel mill.

获取价格

Modern grinding balls sorting machines - ResearchGate

Contact address: e-mail: pawel.piekaj@agh DOI 10.2478/ntpe-2019-0009 2019 Volume 2 Issue 1 pp. 86-95 Modern grinding balls sorting machines

获取价格

How to Process Gold Ore? 4 Gold Processing Steps Mining Pedia

2022年5月19日 The grinding operation of rock gold mine usually adopts one-stage or grid ball mill + overflow ball mill for two-stage grinding. The second stage grinding operation forms a closed loop with a spiral classifier or a hydrocyclone to ensure the grinding fineness. ... Gold grinding and classification machines: Wet grid ball mill, wet overflow

获取价格

19 Types of Grinding Machines and Their Uses Xometry

2023年11月2日 This article explores 19 types of grinding machines and examines how they work, how they differ, and how much they might cost you. 1. Angle Grinder. An angle grinder, also referred to as a side grinder, uses a grinding disc to cut, deburr, polish, and clean. Angle grinders are unique in that they’re portable, handheld devices.

获取价格

Milling Machine Basics: Types, Classifications, Cutting Tools

2022年8月29日 Milling Machine Classification. In general terms, milling machines can be classified by the orientation of their spindle (or spindles, in the case of multi-spindle machining centers). In most cases, this is either horizontal or vertical, although the line has grown increasingly blurry with the development of 5-axis machining centers, so-called ...

获取价格

Ball Grinding System - Royal Master Grinders

TG-12X4 Models TG-12X8 Models Legacy Products Engineering Accessories Automation Dressing Options Ball Grinding System Grind up to six 1.4″ balls in less than 8.4 seconds Royal Master has developed a ball grinding system from the ground up using our Robust TG-12×8 platform. Built for longevity and with the latest in operator interface and standard

获取价格

DRAFT TANZANIA STANDARD - TBS

Note 1: The calculation of grinding balls surface area and grinding balls volume performed by nominal diameters. Note 2: The steel density is 7.85 g/cm3 during grinding balls mass calculation. 11. Hardness The balls hardness after heat treatment must comply with the requirements set out in Table 3 and 4. Table 3: Ball hardness values for steel ...

获取价格

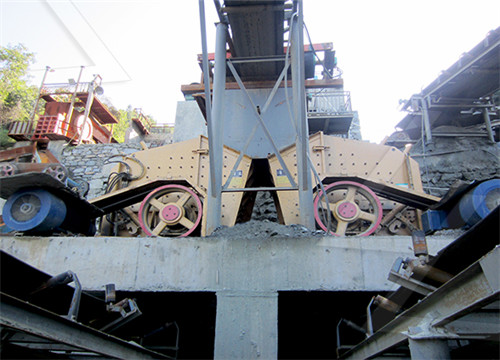

Classification of grinding media sorting machine currently used

At the beginning, the sorting process is exactly the same as in the case of the drum sorter -the grinding balls which before leaving the drum did not reach any of the classification chutes, get to ...

获取价格

Schedule B Book - Chapter 84 - Census.gov

2024年1月18日 North American Industry Classification System (NAICS) Economic Indicator Database. Export Training ... Heading 8482 applies, inter alia , to polished steel balls, the maximum and minimum diameters of which do not differ from the nominal diameter by more than 1 percent or by more than 0.05 mm, whichever is less. ... - Other

获取价格

Grinding Balls Rods - 911 Metallurgist

2016年10月20日 Grinding Balls. Steel balls ranging from ¾ to 5 in. in diameter are used. Rods range from 1½ to 4 in. in diameter and should be 3 to 4 in. shorter than the inside mill length. Tube mills are usually fed balls smaller than 2 in., whereas 4- or 5-in. balls are more commonly used for ball-mill grinding.

获取价格

Energy-Efficient Technologies in Cement Grinding IntechOpen

2016年10月5日 The energy consumption of the total grinding plant can be reduced by 20–30 % for cement clinker and 30–40 % for other raw materials. The overall grinding circuit efficiency and stability are improved. The maintenance cost of the ball mill is reduced as the lifetime of grinding media and partition grates is extended. 2.5.

获取价格

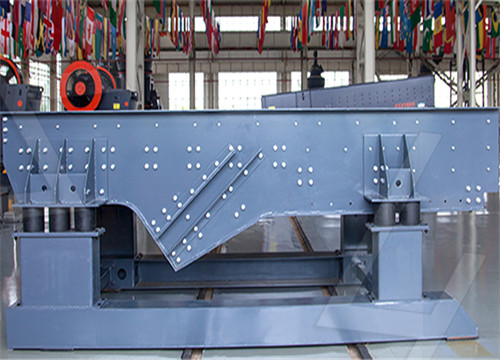

Spiral Classifier - JXSC Machinery - Mineral Processing

Spiral Classifier. Capacity: 21-1785 t/24h (over flow); 145-23300t/24h (returned sand); Up to 150% spiral submergence. Spiral diameter: 500-3000mm; Single, double or triple pitch spirals are available. Application: It is often combined with a ball mill to form a closed-circuit cycle to divert ore sand; classification in the grinding circuit of ...

获取价格

How to Select Grinding Media for your Application - Thomasnet

2022年8月4日 Grinding machines use friction, attrition, or compression to smooth out a metal product’s surface.There are several types of grinding machines designed to deliver different levels of finite smoothness. For example, a ball-grinding mill is an excellent fine grinder for cement products, but may not work for more extensive smoothing projects..

获取价格

Grinding Balls Rods - 911 Metallurgist

2016年10月20日 Grinding Balls. Steel balls ranging from ¾ to 5 in. in diameter are used. Rods range from 1½ to 4 in. in diameter and should be 3 to 4 in. shorter than the inside mill length. Tube mills are usually fed balls smaller than 2 in., whereas 4- or 5-in. balls are more commonly used for ball-mill grinding.

获取价格

Energy-Efficient Technologies in Cement Grinding

2016年10月5日 The energy consumption of the total grinding plant can be reduced by 20–30 % for cement clinker and 30–40 % for other raw materials. The overall grinding circuit efficiency and stability are

获取价格

Spiral Classifier - JXSC Machinery - Mineral Processing

Spiral Classifier. Capacity: 21-1785 t/24h (over flow); 145-23300t/24h (returned sand); Up to 150% spiral submergence. Spiral diameter: 500-3000mm; Single, double or triple pitch spirals are available. Application: It

获取价格

How to Select Grinding Media for your Application - Thomasnet

2022年8月4日 Grinding machines use friction, attrition, or compression to smooth out a metal product’s surface.There are several types of grinding machines designed to deliver different levels of finite smoothness. For example, a ball-grinding mill is an excellent fine grinder for cement products, but may not work for more extensive smoothing projects..

获取价格

Grinding Machines SpringerLink

2019年1月1日 So a 2nd-level classification scheme of grinding machines with rotating tools is proposed and presented in Fig. 2. This scheme again may be used for all machines classified in level 1. ... Combi-machines, capable of multiple surface treatment processes, namely, grinding combined with polishing, roller or ball burnishing, and even laser ...

获取价格

Methods to Survey and Sample Grinding Circuits for Determining

2023年1月20日 This guideline covers surveying and sampling Autogenous Grinding (AG), Semi-Autogenous Grinding (SAG), rod, and ball mill circuits within the normal range of application. The intended application of this analysis is to treat a complete grinding circuit as a singular process block, irrespective of the number of grinding stages or internal

获取价格

Chapter 17: Grinding Methods and Machines - American Machinist

Belt grinding has become an important production process, in some cases replacing conventional grinding operations such as the grinding of camshafts. Belt speeds are usually in the range of 2,500 to 6,000 ft/min. Machines for abrasive-belt operations require proper belt support and rigid construction to minimize vibration.

获取价格

How Grinding Balls Sorting Machines Revolutionize Material

2023年8月24日 Grinding balls sorting machines have emerged as a game-changer in this realm, offering a seamless and efficient solution that revolutionizes material processing. By automating the sorting process and leveraging advanced technologies, these machines have become an indispensable asset for manufacturers across industries.

获取价格

The Classification of Ball Bearings, Roller Bearings and Parts

The Classification of Ball Bearings, Roller Bearings and Parts Thereof April 2012 . Other bearing innovations continued to emerge in the 1800’s and 1900’s. In 1883, Friedrich Fischer created the ball-grinding machine, a machine to mill and grind balls of equal size and exact roundness. 11. This creation spawned the rolling bearing industry

获取价格

Grinding Mills - Common Types - 911 Metallurgist

2016年11月7日 In Fig. 1.3 is shown a large ball mill, designed for the dry grinding of limestone, dolomite, quartz, refractory and similar materials; this type of mill being made in a series of sizes having diameters ranging from about 26 in. to 108 in., with the corresponding lengths of drum ranging from about 15 in. to 55 in.

获取价格

A survey of machine-learning techniques for condition monitoring

2021年2月1日 These basic concepts are not confined to grinding machines but are applicable to all sorts of rolling ball bearings. After presenting the physical basics, this paper outlines the major state-of-the-art machine-learning concepts for predictive maintenance of bearings: One research direction is the detection of faults by means of classification ...

获取价格

Analyzing process parameters for industrial grinding circuit based

2023年9月1日 The grinding and classification processes are systematic engineering that must comprehensively consider the influence of several factors to ensure good grinding fineness. Based on the machine learning method, this study analyzed the full process parameters (i.e., ball mill power, fresh ore feed rate, hydrocyclone feed pump power,

获取价格

Grinding balls, buy metal balls from Metinvest manufacturer

Classification and properties. Steel grinding balls for ball mills can be manufactured according to both international and national standards (e.g., DSTU 8538, GOST 7524) and according to specifications of manufacturers and consumers. The main features and classifiers are: Product material: iron, steel, carbide material, ceramics

获取价格

Ball Mill Grinding Theory - Crushing Motion/Action Inside

2017年4月28日 Two Stage Grinding. The object of these tests was to determine the capacity of ball-mills when crushing in two stages. The conditions of the test were as follows: First Stage of Ball Milling. Feed rate, 15.31 T. per hr. Classifier, Dorr duplex with baffled overflow. Ball load, 28,000 lb. of 3- and 2-in. balls. Speed, 23.8 r.p.m. Ball-mill power ...

获取价格