مسكن

>

productivity of gyratory crusher

مسكن

>

productivity of gyratory crusher

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

productivity of gyratory crusher

Simulation and optimization of crushing chamber of gyratory

2021年5月1日 Compared with the gyratory crusher, this type of crusher has a relatively small crushing force and compression ratio, and their changes are small. Therefore, the

获取价格

Gyratory crusher productivity analysis based on kinematic ...

2016年8月10日 The results of the study showed that the highest partial productivity of labor 2,78, capital 1,22, raw materials 203,47, and other input 67,77. The highest total

获取价格

Simulation and optimization of gyratory crusher ... - ResearchGate

2020年7月1日 The feasibility of the optimization results is verified, the productivity and the crushing force can be increased by 8.4% and 2.25 times, respectively. Meanwhile, the

获取价格

Mathematical Modeling and Multi-Criteria

2023年5月17日 Analytical expressions were derived to determine the rational rotation speed and productivity of the crusher under consideration.

获取价格

Chamber Optimization for Comprehensive

2021年3月15日 This study aims to analyze the impact of key structural parameters such as the bottom angle of the mantle, the length of the parallel zone, and the eccentric angle on the productivity and product quality of

获取价格

Mathematical Modeling and Multi-Criteria

2023年5月17日 As a result of its solution, the rational shape of the working chamber cheek of the single-roll gyratory crusher was established, representing a logarithmic spiral arc. Analytical expressions were derived

获取价格

Minerals Free Full-Text Torque Analysis of a Gyratory Crusher

2021年8月13日 Gyratory crushers are the most common machine used in the primary crushing in the copper mining industry of Chile and worldwide, and they are designed for

获取价格

Mathematical Modeling and Multi-Criteria Optimization of

2023年5月17日 productivity in the presence of small dimensions, and can be used for crushing solid rocks. Due to such small overall dimensions, crushers of this type can

获取价格

What Are the Differences Between The 7 Types of

2023年2月15日 But the production of gyratory crusher is much higher than jaw crushers'. Therefore, if you require a large production and no focus on particle shape, you can choose gyratory crusher, Vice versa. If

获取价格

Mathematical Modeling and Multi-Criteria Optimization of

2023年5月17日 One of the promising options is using single-roll gyratory crushers [2]. Figure 1 shows a cross section of the working chamber of such a crusher. Figure 1. Working chamber of a single-roll gyratory crusher. Shaft 3 is located in housing, 1, equipped with reinforcing plates, 2. Working roll, 4, is installed on it eccentrically by means of bearings.

获取价格

Primary and Secondary Crushing: Understanding the

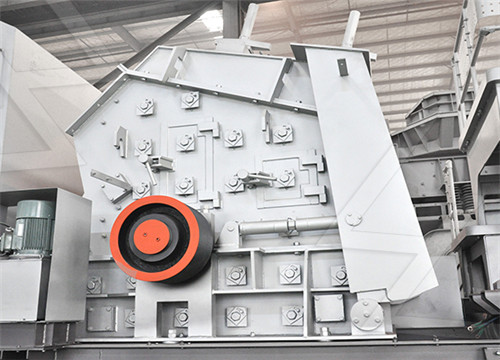

2023年2月28日 The secondary crusher has a size reduction ratio ranging from 3:1 to 5:1. The secondary crusher can be a cone crusher, impact crusher, or gyratory crusher, depending on the hardness,

获取价格

Gyratory Crusher - Mining Fundamentals - AZoMining

Gyratory crushers are known for their high production rates, with a higher capacity than a jaw crusher. In order to get cubical material out of a gyratory crusher, it should be choke fed. Gyratory crushers are not suitable for crushing clay, as clay will clog the crusher. Construction and Working of Gyratory Crushers

获取价格

SANDVIK CG800i GYRATORY CRUSHER SERIES

alarms to protect the crusher. 365 Lifecycle Services support your new equipment throughout its entire lifecycle, helping you increase productivity by up to 10%. Get genuine parts, service solutions and extensive training that deliver lower operating costs, improved product quality and maximum productivity. Product picture to be placed ...

获取价格

Simulation and optimization of gyratory crusher ... - ScienceDirect

2020年10月1日 1. Introduction. The gyratory crusher is widely used in primary crushing of metal ore such as iron ore and copper ore due to its high productivity and large feed inlet [[1], [2], [3]].In recent years, with the growth of the world's population, the development of urbanization and the improvement of living standards, the demand for the ore continues

获取价格

Gyratory Crusher (Gyratory Crushers Explained) - saVRee

A primary crusher is designed to receive run-on-mine (ROM) rocks directly from the mines. Gyratory crushers typically crush to reduce the size of aggregate to a maximum of about one-tenth of its original size. Gyratory crushers are always installed vertically orientated. A gyratory crusher’s size is classified by:

获取价格

Gyratory Crusher - an overview ScienceDirect Topics

The gyratory crusher shown in Figure 2.6 employs a crushing head, in the form of a truncated cone, mounted on a shaft, the upper end of which is held in a flexible bearing, whilst the lower end is driven eccentrically so as to describe a circle. The crushing action takes place round the whole of the cone and, since the maximum movement is at the

获取价格

Stone Crushers: A Technical Review on Significant Part of

Aggregate production 1 Introduction Crushers are widely used equipment to reduce the large size rocks into stones finer than about 50–100 mm in size [1]. In infrastructure industry, these equipment are ... Gyratory Crusher Analytical + Design Control system was designed and added to the crusher for controlling the charge level. Simulation ...

获取价格

Stone Crushers: A Technical Review on Significant Part of

2022年5月14日 Another type of primary crushers commonly used by quarrying industries is the gyratory crushers which consist of long length conical shaped, hard steel crushing elements suspended from top. ... Chamber optimization for comprehensive improvement of cone crusher productivity and product quality. In: Mathematical problems in engineering

获取价格

Crusher Efficiency Calculations - 911 Metallurgist

2014年9月15日 The aggregate production requires the consideration of several crushers, feeders and screens. This is not intended to be a typical situation, though it does involve common crusher and screen units often used in aggregate plants. ... Another possible solution to this problem would be to use a gyratory crusher for the primary crushing

获取价格

Simulation and optimization of gyratory crusher ... - ScienceDirect

2020年10月1日 The gyratory crusher is widely used in primary crushing of metal ore such as iron ore and copper ore due to its high productivity and large feed inlet [[1], [2], [3]]. ... The results indicate that the proposed calculation method can effectively estimate the productivity of eccentric roll crushers. Failure analysis of eccentric bushings in ...

获取价格

Torque Analysis of a Gyratory Crusher with the Discrete

Several gyratory and cone crushers have been simulated with DEM. Litcher et al. proposed a two-way coupling DEM-PBM (Population Balance Model) model of cone crushers [13], where the PBM was used to represent the size reduction in the particles. A B90 cone crusher and a HP100 cone crusher were simulated, and the particle size

获取价格

Crusher Closed / Open Side Setting Program - Global Physical

Crusher Vision will: Crusher Vision is an automated system for determining closed-side setting (CSS) in a gyratory crusher by measuring the gap between the concave and mantle, as shown in Fig. 1. The standard method for determining wear on the mantle is to lower a galvanized steel bucket or a lead ball into the crusher then measuring the

获取价格