مسكن

>

feed hopper design stone crushing plant

مسكن

>

feed hopper design stone crushing plant

منتج

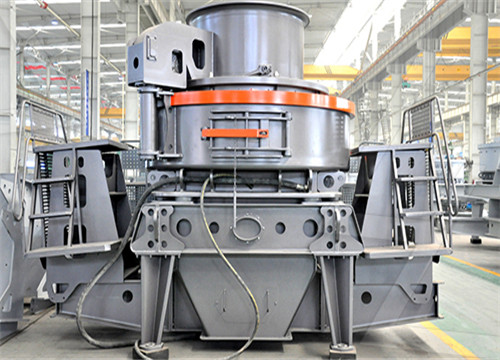

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

feed hopper design stone crushing plant

How the stone crusher hopper is designed? - LinkedIn

2023年3月13日 Here are some general guidelines for designing a stone crusher hopper: 1.Size: The size of the hopper should be designed to hold enough material to ensure uninterrupted operation of the...

获取价格

Crushing Plant Flowsheet Design-Layout - 911 Metallurgist

Crusher Plant LayoutCrushingScreeningMost crushing plants are now designed on the lines shown in Fig. 1, which is a diagrammatic view of a two-stage arrangement. The ore from the mine is dumped in the coarse ore bin, from which an automatic feeder delivers it over a grizzly to the primary breaker, the latter being of the jaw type in the case of a small plant a在911metallurgist上13

Crushing and Screening Agg-Net

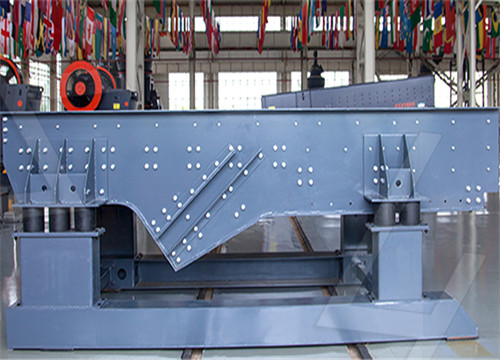

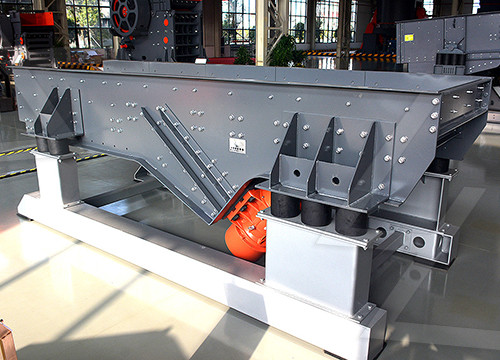

2012年10月15日 Hopper design. One of the first steps in the process is to select the equipment to load the primary hopper. The truck size and number of trucks or loaders needs to be determined to evaluate the hopper capacity. Typically, the minimum hopper live load capacity is approximately 1.5 times the size of the unit dumping into the hopper.

获取价格

Feed Hopper Material Feed System Superior

Operators don’t have the time or patience to waste maintaining feed hoppers or bins. They want equipment that is easy to use, consistently performs and is designed durablyjust in case their bucket gets unruly.

获取价格

The Importance of Hopper Feeder Safety When

2021年1月10日 Among the various components of rock crushing equipment, the hopper feeder could be regarded as the one that presents the most risk. After all, the hopper feeder attracts heavy vehicles that

获取价格

Tips for designing an efficient crushing and screening operation

2013年4月4日 There are several considerations in designing an efficient crushing and screening plant. The first is the raw materials to be crushed. ... FEEDER AND HOPPER DESIGN {{image2-a:r-w:200}}One of the first steps in the process is to select the equipment to load the primary hopper. ... This overcomes the fluctuations in the feed from the

获取价格

My Plant Planner - Metso

A free-to-use drag and drop configurator that helps you design more productive and efficient plants through real-time insights. Design and simulate a new crushing and screening plant in 3D or test how upgrading your current equipment can improve performance. My Plant Planner is packed full of unique features and insights to help you plan your ...

获取价格

McLanahan Vibrating Grizzly Feeders

Why McLanahan Vibrating Grizzly Feeders. The McLanahan Vibrating Grizzly Feeder has a history of reliability and durability. McLanahan offers feeders in five different widths to match up to the crusher opening width. For example, McLanahan designs feeders with shallower sides for use in portable plants where over plant height is limited.

获取价格

Scientific Methods to Design Crushing and Screening Plants

Bond's Third Theory of Comminution' calculates the amount of power required to reduce the material by the equation: When adapted to the crushing process, ower becomes a function of reduction ratio and work in iex: Where W = power in kWh per st W, = Bond's crushing work index Pno = size in pm, 80% product passing Fgo = size in pm, 80% feed ...

获取价格

Crushing and Screening Handbook - AusIMM

Whether you need a single crusher, a multi-stage process or a complete plant, we assist you with the right design for the most cost-eff ective crushing process. We are the world’s leading supplier of both unit machines and complete aggregates processing systems. Comprehensive process solutions Your system may involve a whole series of proc-

获取价格

Stone crusher plant Henan Deya Machinery Co., Ltd.

2022年7月5日 2.1 Primary crushing stage. 2.1.1. Currently, there are three main types of primary stone crushers: jaw crushers, impact crushers and gyratory crushers. The impact crusher, as a primary crusher, is only suitable for medium to soft rocks, such as limestone, and thus its use is limited. Large jaw crushers with a maximum feed length of up to 1m ...

获取价格

(PDF) Crushing and Screening Handbook - Academia

EROL YILMAZ. Crushing plants are of great interest in reducing a particle size of rocks and ores as milling operations need to consider sustainable development. Since the crushing plants operate under harsh conditions and involve very abrasive material, multiple factors can influence their performance. This paper assesses a number of factors ...

获取价格

Primary Crusher - an overview ScienceDirect Topics

The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator. Secondary coal crusher: Used when the coal coming from the supplier is large enough to be handled by a single crusher. The primary crusher converts the feed size to one that is acceptable to the secondary crusher.

获取价格

PQ University Lesson 8- Screening #Site Title - Pit and Quarry

2019年10月11日 Material is fed directly onto the screen. Scalpers are ideal for sorting materials before crushing, processing scrap metals and recyclables, and to extract rock from dirt on construction sites. Hopper size is typically 12-ft. wide with an option to upgrade to a 14-ft. wide. Those extra 2 ft. can capture more product and prevent spillage.

获取价格

6 Granite Crushers for Efficient Granite Rock Crushing

2023年5月12日 As a professional mining equipment manufacturer, Ftmmachinery can provide you with efficient and solid rock crushers and help design a reasonable granite stone crushing plant according to your needs (output, grain shape, particle size, working site). Taking the granite sand making line as an example, the crushing process is as

获取价格

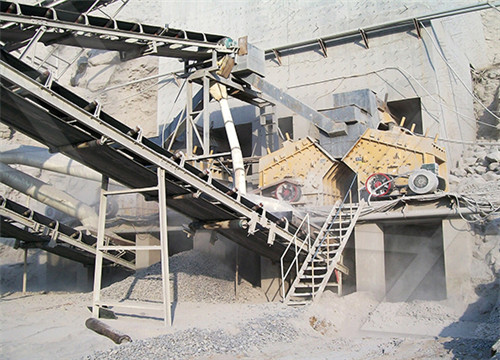

Crushing plant - Wikipedia

A Crushing plant is one-stop crushing installation, which can be used for rock crushing, garbage crushing, building materials crushing and other similar operations. Crushing plants may be either fixed or mobile. A crushing plant has different stations (primary, secondary, tertiary, ...) where different crushing, selection and transport cycles are done

获取价格

Primary Crusher - an overview ScienceDirect Topics

Gyratory and Cone Crusher. In Mineral Processing Design and Operations (Second Edition), 2016. Abstract. Detail descriptions of designs are given of large gyratory crushers that are used as primary crushers to reduce the size of large run-of-mine ore pieces to acceptable sizes. Descriptions of secondary and tertiary cone crushers that usually follow

获取价格

PQ University Lesson 8- Screening #Site Title

2019年10月11日 Material is fed directly onto the screen. Scalpers are ideal for sorting materials before crushing, processing scrap metals and recyclables, and to extract rock from dirt on construction sites. Hopper

获取价格

6 Granite Crushers for Efficient Granite Rock Crushing

2023年5月12日 As a professional mining equipment manufacturer, Ftmmachinery can provide you with efficient and solid rock crushers and help design a reasonable granite stone crushing plant according to your needs (output, grain shape, particle size, working site). Taking the granite sand making line as an example, the crushing process is as

获取价格

Crushing plant - Wikipedia

A Crushing plant is one-stop crushing installation, which can be used for rock crushing, garbage crushing, building materials crushing and other similar operations. Crushing plants may be either fixed or mobile. A crushing plant has different stations (primary, secondary, tertiary, ...) where different crushing, selection and transport cycles are done

获取价格

Design and Evaluation of an Expert System in a Crushing

2.1. Specifications of the Crushing Plant The mineral derived from both the open-cut and ground-based exploitation must be prepared in a crushing plant; then, if necessary, acid is added to achieve a controlled grain size to ensure a good permeability coefficient of the solution. Crushing is a unitary operation of size reduction by the

获取价格

How to Design a Stone Crusher Plant Layout - LinkedIn

2023年5月11日 A stone crusher plant designer follows three steps to create the layout: • Process design. • Equipment selection. • Layout. The principal design parameters driving the crushing plant and ...

获取价格

11.19.1 Sand And Gravel Processing - US EPA

After being transported to the processing plant, the wet sand and gravel raw feed is stockpiled or emptied directly into a hopper, which typically is covered with a "grizzly" of parallel bars to screen ... and handling and transfer operations associated with stone crushing can be found in Section 11.19.2, "Crushed Stone Processing." In the ...

获取价格

NFDC - Safe Use of Mobile Crushers Screening Plant - Issuu

2015年3月11日 The feed should then be controlled from the machine feeding the crusher by varying the loading rate into the feed hopper. 1.7 Action when a crusher becomes blocked Have a nominated person to ...

获取价格

Proper design of dump hoppers for apron feeders - LinkedIn

2016年8月2日 Figure 1 - Apron Feeder application to dump hopper and feeding primary crushing plant. Primary apron feeders are for high-capacity applications up to 10,000 tph, speed between 10 to 25 m/min ...

获取价格

How To Design Aggregate Making Plant MC - beidoou

4. Pay attention to the quality of sand and stone. Good quality sandstone is gradually replacing poor quality sandstone. In addition, with the continuous improvement of building standards, the demand for fine sandstone is also increasing. 5. Pay attention to environment protect. Environmental protection is becoming more and more important.

获取价格

How to check the stone crusher and daily maintenance? - LinkedIn

Published Feb 7, 2023. + Follow. To check the stone crusher, you should do the following checks regularly: Inspection of the feeding system: Check if the feeding device and the feed hopper are not ...

获取价格

Hopper Discharge Systems - Aumund

The hopper inside is either lined with wear-resistant material or fitted with a polished lining to prevent cohesive material from sticking to the hopper walls. Fig. 1 The special design of the Drag Chain Conveyor type TKF, in this example used for discharge of raw coal, allows to build the receiving hopper with a relatively small depth.

获取价格

Jaw Crushers - Parker Plant

The RockSledger down-thrust single toggle design provides a more aggressive crushing motion and subsequently higher capacities are achieved. Six standard models in the RockSledger range provide outputs from 70tph to over 850tph and are at the core of the designs used by Parker in their ranges of static, transportable and mobile jaw crushing

获取价格

Crushing Plant - Crushing Machine - Crusher Plant - Manufacturer

Stone Crusher Plants Equipments. Hopper Feeders: The offered hopper feeders work continuously and evenly feed lump, particle and powdered materials from hopper to jaw crusher. Jaw Crushers: Royal Engineering offers heavy-duty jaw crushers which are accessible as standalone units, modular assemblies and portable assemblies and as a

获取价格