مسكن

>

typical crusher plant design

مسكن

>

typical crusher plant design

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

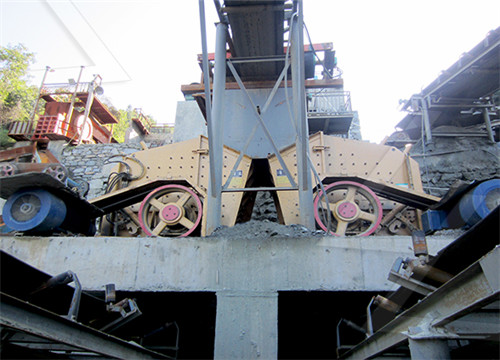

typical crusher plant design

The Ultimate Guide to Stone Crusher Plant Design

2023年2月28日 Stone crusher plant design is a crucial factor in the efficient operation of the crushing process. The primary goal of plant design is to achieve the desired product size and capacity while

获取价格

Crushing and Screening Handbook - AusIMM

the crusher and scalp out fi nes. Primary gyratory crushers – ideally suited to all high-capacity primary hard rock crushing applications. Jaw crushers – we have more

获取价格

Crushing Systems -

Design Raptor cone crushers have been designed with input from plant operations and maintenance people around the globe. This input has led to many designs and features

获取价格

Crushing and Screening Handbook - AusIMM

the crusher and scalp out fi nes. Primary gyratory crushers – ideally suited to all high-capacity primary hard rock crushing applications. Jaw crushers – we have more installed jaw crushers than anyone in the world. The lead-ing choice due to their high reduction ratio and heavy duty design. Cone crushers – capacities available to suit all

获取价格

Primary Crusher Selection Design - 911 Metallurgist

2015年12月23日 A crusher’s wear parts need to last as long as operationally-economically possible. Typical numbers are for liner and mantles to have a useful wear-life of almost 2,000,000 tonne on abrasive taconite and 9,000,000 tonnes on porphyry copper ores. Dependability and long service life are landmarks of good primary crusher design of up

获取价格

Crushing Screening Plant Design Factors - 911

2016年4月14日 Crushing Plant Design and Layout ConsiderationsCrushing Circuit “A’’ shows a small simple layout for use in mills up to 100 tons. In order to keep the flowsheet simple, and because

获取价格

Stone Crusher Plant Setup - Machinery Partner

The stone crusher plant consists of a crushing setup of excavators, feeders, primary and secondary crushers and screeners. They all work together to crush stone as efficiently as possible. Conveyors connect everything, moving the crushed material from one station to the next. Stone crusher plant equipment is divided into two categories:

获取价格

Expected or Typical "life span" of wear parts of jaw crusher - Crushing

It should be three crushing plants as well. I don't remember expert names (or company names) involved in the study. But I remember a few figures they operated with. For limestone aggregate cost of wear/spare parts was 3-7% of new plant cost per 2000 hours, for medium abrasive granite - 5-10%, for high abrasive material - 7-15%.

获取价格

Estimate Jaw Crusher Capacity - 911 Metallurgist

2016年2月17日 From Allis-Chalmers’ Superior Primary and Secondary Crushers. ° Actual required depends on stone hardness, reduction ratio, and so on. If a 60-in. gyratory crusher is to process material from a quarry where a shovel loads the raw material, the shovel would probably have to have a dipper capacity of at least 5 cu yd to be compatible.

获取价格

Below the surface: Setting up an underground primary jaw crusher

2014年4月1日 Jaw crushers are the most common solution in underground applications when the throughput is below 1000 tonnes per hour, depending somewhat on the scalping solutions. Above 1000 tph, primary gyratory crushers are an option. After the throughput reaches 2000 tph, jaw crushers are very rare, with the exception of a parallel plant layout.

获取价格

Layout of a four-stage crushing plant for ballast production.

For this reason, state of the art cone crusher control technology in the mineral processing industry seems to be lagging; the crushing stage is overlooked because it is only a part of a mining ...

获取价格

8 Tips for Setting Up a Crusher Plant Mellott

2019年9月4日 Here are eight tips to make that happen. 1. Set up the plant at the right time. The best season to set up a crushing plant is in the fall. The weather is typically temperate enough for crews to work consistently, unlike summer or winter, which can pose dangers from the heat or cold. Spring can work as well but in areas such as the east coast ...

获取价格

Design and Performance Evaluation of a Stone Crusher

2021年10月7日 The machine was fabricated using locally available materials. The fabricated stone crusher was tested and the actual capacity was found to be 301 kg/h with a through-put efficiency of 75.4 %. The ...

获取价格

Rock Crushing Rule of Thumb - 911 Metallurgist

2015年12月16日 Crusher Design. The approximate capacity of a jaw crusher for hard rock application at a typical setting may be obtained by multiplying the width by 10 to get tonnes per hour. For example, a 48 by 60 crusher will have a capacity in the order of 600 tph when crushing ore in a hard rock mine. Source: Jack de la Vergne

获取价格

The process design of gold leaching and carbon-in-pulp

A block-flow diagram of a typical CIP plant for a non-refractory gold ore is shown in Figure 2. ... Detailed plant design Construction commissioning operations Thickening Leaching Crushing and/or milling Residue ... Primary crushing 2.7 Ores Storage 2.7 Milling 21.1 Thickening 5.1 Leaching 7.5 Adsorption 5.2 Elution 3.5

获取价格

PQ University Lesson 2: Site Selection Plant Design

2019年8月5日 The selection of an appropriate processing circuit for a specific material is one of the most important decisions in the design of a processing plant. The importance is related to the fact that the capital and operating costs for the crushing/screening portion generally represent the major portion of the plant costs.

获取价格

(PDF) Crushing Plant Dynamics - ResearchGate

2015年10月15日 The capability of process simulation to replicate crushing plant performance and implementation in fullscale plant design and operation has increased over the past couple of decades [9, 10, 20,21 ...

获取价格

Rock Crushing Rule of Thumb - 911 Metallurgist

2015年12月16日 Crusher Design. The approximate capacity of a jaw crusher for hard rock application at a typical setting may be obtained by multiplying the width by 10 to get tonnes per hour. For example, a 48 by 60 crusher will have a capacity in the order of 600 tph when crushing ore in a hard rock mine. Source: Jack de la Vergne

获取价格

The process design of gold leaching and carbon-in-pulp

A block-flow diagram of a typical CIP plant for a non-refractory gold ore is shown in Figure 2. ... Detailed plant design Construction commissioning operations Thickening Leaching Crushing and/or milling Residue ... Primary crushing 2.7 Ores Storage 2.7 Milling 21.1 Thickening 5.1 Leaching 7.5 Adsorption 5.2 Elution 3.5

获取价格

PQ University Lesson 2: Site Selection Plant Design

2019年8月5日 The selection of an appropriate processing circuit for a specific material is one of the most important decisions in the design of a processing plant. The importance is related to the fact that the capital

获取价格

(PDF) Crushing Plant Dynamics - ResearchGate

2015年10月15日 The capability of process simulation to replicate crushing plant performance and implementation in fullscale plant design and operation has increased over the past couple of decades [9, 10, 20,21 ...

获取价格

Small Crushing Plant Operating Guide - 911 Metallurgist

2016年1月26日 This EXAMPLE Small Crushing Plant is designed to crush 500 tonnes per day, operating 12 hours per day with an availability of 70%.The Plant will crush run-of-mine material (-16″) to 100%, passing 5/8″ at a rate of 60 tonnes per hour. Start-stop stations are provided for all equipment in this Plant at the crusher control panel, to facilitate remote

获取价格

What Type of Crusher Is Best for Primary Crushing? - McLanahan

2021年3月25日 Primary crushers reduce large run-of-mine material, such as rocks and ore lumps, into smaller sizes for further processing downstream, whether that be transport to additional crushers or to a wet processing plant. It is the first stage in the crushing process that can sometimes include secondary, tertiary and even quaternary crushing stages ...

获取价格

Crusher Efficiency Calculations - 911 Metallurgist

2014年9月15日 Crushing Screening Plant Assessment Example. Quarry rock of 12 in. maximum size is to be handled in a two-stage crusher plant at the rate of 70 tons per hour. The maximum size of output is to be 1½ in., and separation of materials over 1 in. size and the minus 1 in. in the output is required. Select a jaw crusher like those included in this ...

获取价格

Cone Crusher Plant Design - 911 Metallurgist

2017年6月23日 A) Stacked Design. This design is intended to operate in open circuit. With fairly constant ore characteristics and where the feed to the fine crushing plant contains less than 15 percent minus 19MM (¾”) , screening ahead of Standard can be omitted. The Standard crusher closed side setting in this case is usually between 28MM and 37MM (1

获取价格

Impact Crusher Working Principle - 911 Metallurgist

2015年6月23日 Impact crushing crushing is the reduction of materials by rubbing; primarily a grinding method. Shear crushing is accomplished by breaking along or across lines of cleavage. It is possible, when required, for a crusher to use a combination of two or three of these principles. The selection or sizing of a crusher is much helped by

获取价格

Should know all about Stone Crusher Plant - Machine Thug

Let’s clear what stone crusher plant actually does. “Stone crusher plant is a machine designed to reduce the large stone, granites, marble, lime rocks into the smaller size and output gravel, dust, different size of the material.”. Stone crusher plants used worldwide. It is available with different-2 capacity, design, and utility.

获取价格

Primary Jaw Crusher – Everything You Need to Know - AGICO

2023年2月28日 A primary jaw crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust. It is used in many industries, including mining, construction, and demolition, to crush materials such as rocks, coal, and ores. A primary jaw crusher consists of two plates, one stationary and one movable, which form a V-shaped

获取价格

Primary Crusher - an overview ScienceDirect Topics

6.2.3 Roll crusher circuit design. Roll crushers are generally not used as primary crushers for hard ores. Even for softer ores, such as chalcocite and chalcopyrite, they have been used as secondary crushers. ... for example, crushing plant, silo discharge system, train unloading system, etc. ... Typical capacities (t/h) Gyratory crusher ...

获取价格

Crushing Systems -

Design Raptor cone crushers have been designed with input from plant operations and maintenance people around the globe. This input has led to many designs and features that reduce maintenance time and increase production. Raptor cone crushers’ critical load bearing components meet specifications that typically exceed what is commonly

获取价格

HPGR High Pressure Grinding Rolls - 911 Metallurgist

2016年7月13日 A Cerro Verde expansion used a similar flowsheet as the 2006-commissioned circuit to triple circuit capacity. The expansion circuit includes eight MP1250 cone crushers, eight HPGRs (also 2.4 x 1.7-m units, with 5 MW each), and six ball mills (22 MW each), for installed comminution power of 180 MW. and a nameplate capacity of

获取价格