مسكن

>

antimony ore separator gravity separation of antimony ore

مسكن

>

antimony ore separator gravity separation of antimony ore

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

antimony ore separator gravity separation of antimony ore

Current processing technology for antimony-bearing ores a

1989年1月1日 The high density of antimony minerals and their tendency to grind to slime (hardness of 2.5 on Mohs' scale) make gravity separation in the mill circuit an interesting possibility for the first step in the process.

获取价格

Beneficiation of Antimony Oxide Ore: A Review - Springer

ness of antimony oxide ore is lower than other metal ores, and it is easily overcrushed. In addition, gravity has a limited effect on the selection of fine-grained antimony oxide

获取价格

Current processing technology for antimony-bearing ores a

1989年1月1日 Because of the rise in gold prices, some antimony ores should really be viewed as gold ores with antimony as a by-product. In this context, cyanide leaching is

获取价格

Three Methods To Antimony Ore Beneficiation And Processing

2023年12月27日 Therefore, the gravity separation method is an ideal method to treat antimony ore. The primary condition for gravity beneficiation is monomer dissociation.

获取价格

Concentration characteristics of a complex antimony ore

2019年1月29日 Froth flotation, gravity concentration, electrostatic separation, and ore sorting were conducted to introduce the best

获取价格

THE BENEFICIATION OF ANTIMONY ORE BY

2012年10月10日 Antimonite ore is concentrated by physical and physico-chemical methods such as gravity based separators and flotation.

获取价格

Beneficiation of antimony oxide ore: A review - Springer

2017年9月7日 Much attention has been paid to improving the mineral processing technology of antimony oxide based on such experiments. This work presents the latest

获取价格

Antimony Metallurgy SpringerLink

2023年6月7日 Most antimony ores in China are found in Hunan and Guangxi, and the reserves are abundant. Antimonite ore is processed by hand-picking–flotation or heavy

获取价格

A selective process for extracting antimony from refractory gold

2017年5月1日 A complete technological process for extracting antimony from refractory gold ore was proposed. • Antimony can be selectively removed from refractory gold ore

获取价格

BENEFICIATION OF ANTIMONY TAILINGS - ResearchGate

In order to recover antimony from tailings, gravity separation ... 20% Sb by gravity separation was taken with 70% recovery. ... Both antimony content of the ore and

获取价格

Antimony Ore Dressing Process - LinkedIn

2023年3月9日 The antimony ore gravity separation process is applicable to most antimony ore dressing plants, because antimony minerals are minerals with high density and coarse particle size, and are easy to ...

获取价格

Gold Extraction Methods From Three Types of Ore

2024年1月17日 Gravity separation, flotation, magnetic separation, cyanidation, these different extraction methods can maximize gold recovery. Whether you are a small miner or a large mining company, choosing the suitable mineral extraction methods from JXSC can significantly achieve the best results. The methods of extracting gold from quartz vein ore ...

获取价格

Tin Ore Mining Process - JXSC Mineral

In some deposits, pyrite, antimony tin lead ore, cylindrical tin ore, sometimes black sulfur silver tin ore, black boron tin ore, Malayan stone, cassiterite and magnesium tin ore can also be relatively enriched to form industrial value. The main beneficiation of tin ore is gravity separation because it has a higher density than symbiotic ...

获取价格

Antimony Mineral Processing,Antimony Processing,Antimony

Proportion of antimony ore is far greater than proportion of gangue, so it will be separated by using the method gravity separation. This method has many features, high efficiency, energy saving, and environment protection, which can make the low-grade ore enrichment advance. After gravity separation, the antimony will be purified by floatation.

获取价格

5 Methods of Gold-Silver Ore Extraction Mining Pedia

2020年10月16日 When formulating a cyanidation system for silver-containing ore, the following measures should be taken: 1) Leach with concentrated cyanide solution (0.2~0.6% NaCN); 2) Long time (up to 2 to 3 days) leaching; 3) Inflate strongly into the pulp; 4) Add lead salt to the pulp; 5) Bromine cyanidation and so on.

获取价格

Chemie der Erde - Massachusetts Institute of Technology

Antimony is a chalcophile, occurring with sulfur and the heavy metals copper, lead and silver. More than 100 minerals of antimony are found in nature. Some of the more common ones, as summarized by the author, are listed in Table 1. Industrially, stibnite (Sb2S3) is the predominant ore of interest and importance.

获取价格

Mobile Antimony Ore Separation And Concentration Processing

After multi scheme of test, Xinhai finally decided to use gravity separation-flotation process to recycle the antimony ore, and in the test the grade of antimony is 58.71%, the recovery rate of mixed antimony concentrate Is 93.75%. xinhai achieved the maximum intensity of the recovery of the antimony ore, which reduced the environmental ...

获取价格

Wet Pan Mill - JXSC Mineral

Wet Pan Mill also known as amalgamation grinding mill, gold grinder mill, which is a versatile ore grinding pan mill for wet materials. It’s the best replacement for a medium-small capacity ball mill, owing to the excellent performance for wet crushing, small investment, and high output, widely used for separating gold, iron, molybdenum, lead, zinc, antimony, and so on.

获取价格

WHAT'S THE PRINCIPLE OF THE CENTRIFUGAL CONCENTRATOR

2021年8月29日 Gold Ore Concentrate Produced by Centrifuge. Centrifugal concentrator is a new type of equipment developed in modern times to recover useful minerals in fine mud. For example, centrifuges are often used to extract gold from placer gold mines and rock gold mines. The separation effect of gold ore sludge in the gravity field is poor, and ...

获取价格

Common Silver Extraction Methods - Mining-pedia

This scheme is used to process quartz-sulfide ore containing antimony telluride, pyrrhotite, chalcopyrite and other sulfide minerals. ... After the grinding, gravity separation and flotation, the recovery rate of silver was up to 83.95%. ... 8 Types of Iron Ore Magnetic Separator. 2022-03-25(04:03:13) Research on Vat Leaching Test of A Small ...

获取价格

Antimony Mineral Ore

Natural Wholesale Top Quality Antimony Ingot White Color Ore Concentrate Antimony Ingot Raw Gemstone Mineral Specimen $ 1,500 .00 - $ 2,000 .00 Min Order: 5 tons

获取价格

Antimony: The Most Important Mineral You Never Heard Of - Forbes

2021年5月6日 Fortunately for the U.S. at that time, a gold mine in central Idaho called the Stibnite mine was able to step up production of the antimony that is an element in the mine’s ore and helped fill ...

获取价格

Antimony Geoscience Australia

2023年12月19日 In 2019, the modern workings, owned by Mandalay Resources, produced 2.03 kt of antimony 25. Ore is trucked from the Augusta mine portal to the Brunswick plant 2 km away where it is stockpiled, blended, crushed, separated, flotated and filtered. The gravity gold concentrate is refined in Melbourne and the gold-antimony flotation

获取价格

SELECTIVE EXTRACTION OF MERCURY AND ANTIMONY

method to ore ground to approximately 80-mesh, 96.0 percent of the mercury in the ore was recovered in a cinnabar concentrate that assayed 80.3 percent Hg and 1.3 percent Sb. The antimony product contained 80.7 percent of the antimony; it assayed 0.82 percent Hg and 62.3 percent Sb. The mercury product contained 11.6 percent of

获取价格

Antimony Mineral Ore

Natural Wholesale Top Quality Antimony Ingot White Color Ore Concentrate Antimony Ingot Raw Gemstone Mineral Specimen $ 1,500 .00 - $ 2,000 .00 Min Order: 5 tons

获取价格

Antimony: The Most Important Mineral You Never Heard Of - Forbes

2021年5月6日 Fortunately for the U.S. at that time, a gold mine in central Idaho called the Stibnite mine was able to step up production of the antimony that is an element in the mine’s ore and helped fill ...

获取价格

Antimony Geoscience Australia

2023年12月19日 In 2019, the modern workings, owned by Mandalay Resources, produced 2.03 kt of antimony 25. Ore is trucked from the Augusta mine portal to the Brunswick plant 2 km away where it is stockpiled, blended, crushed, separated, flotated and filtered. The gravity gold concentrate is refined in Melbourne and the gold-antimony flotation

获取价格

SELECTIVE EXTRACTION OF MERCURY AND ANTIMONY

method to ore ground to approximately 80-mesh, 96.0 percent of the mercury in the ore was recovered in a cinnabar concentrate that assayed 80.3 percent Hg and 1.3 percent Sb. The antimony product contained 80.7 percent of the antimony; it assayed 0.82 percent Hg and 62.3 percent Sb. The mercury product contained 11.6 percent of

获取价格

Mining Shaking Tables Gravity Separator - JXSC Machinery

Introduction: In gravity separation, the shaking tables (gravimetric tables, shaker tables) are the most widely used and efficient sorting equipment for fine ore separation. The shaking table beneficiation is not just applied as an independent beneficiation method. Still, it is often combined with equipment such as jig separators, centrifugal concentrators, spiral

获取价格

Current processing technology for antimony-bearing ores a

1989年1月1日 Abstract. On the basis of knowledge of the beneficiation properties of antimony minerals reported in the previous part of this article, this second half reviews the state of technology for separation of those minerals and summarizes experience from processing plants. The high density of antimony minerals and their tendency to grind to

获取价格

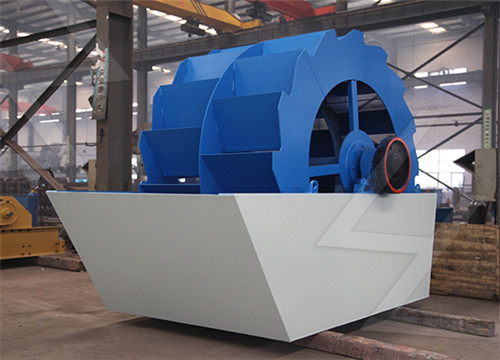

Antimony ore plant equipment - LinkedIn

2023年4月11日 Gravity separator: This equipment is used to separate antimony ore from other materials based on the differences in their specific gravity. Dewatering screen: This equipment is used to remove ...

获取价格

Chrome Ore Process Plant - JXSC Mineral

The raw ore should be crushed by a jaw crusher initially. When it gets a reasonable fineness, it is transported into a vibrating screen through a conveyor and feeder. The screened ores get the next procedure: milling process in the ball mill, then next jigging separation.The milled ore gets into a chrome jig separator for gravity separation. ...

获取价格

Mineral Processing Equipment For Sale - JXSC Machinery

JXSC is a global mining equipment supplier with over 38 years of experience. Mainly include feeder, stone crusher, gravity separation equipment, magnetic separation, flotation machines, laboratory equipment, and support custom.We are a professional manufacturer of high-quality beneficiation equipment covering gold, diamond, copper, manganese, tin,

获取价格

Gravity Separation Equipment - JXSC Machinery - Mineral

The main gravity separation equipment includes jig separators, mobile jig plants, Gemini shaker tables, shaking tables, spiral chutes, and gold centrifugal concentrators. It can process various minerals such as gold, copper, lead-zinc ore, tantalum, niobium, tin, and tungsten, etc. Strong adaptability, high sorting recovery rate and low cost.

获取价格

Sustainability Free Full-Text Present Situation and Research

2023年9月20日 Antimony resources are dominated by antimony sulfide ore, accounting for 85% of the total antimony resources. The main minerals of antimony sulfide ore are stibnite (Sb 2 S 3) and lead antimony sulfide ore (Pb 4 FeSb 6 S 16). Antimony oxide ores are mainly senarmontite and valentinite (Sb 2 O 3) . In the process of beneficiation, to

获取价格

Rutile Processing Beneficiation - JXSC Mineral

Rutile Beneficiation. Rutile ore is a complex ore composed of a variety of minerals. Its grade is low, and the particle size is tiny. The rutile concentrate requires a titanium dioxide content of more than 87.5%. Therefore, the rutile ore process often uses gravity separation, magnetic separation, flotation, and their combined process.

获取价格

Factors That Affecting Shaking Table Gravity Separation

2024年1月11日 2022-03-21. There are many factors affecting the work of the shaking table, among which the main stroke, the number of strokes, the concentration of ore feeding, the amount of ore feeding, the flushing water for the ore body, the lateral slope of the bed surface, and the nature of the ore feeding. (1) Stroke and stroke times.

获取价格

Bentonite Processing Methods And Required Equipment

2024年1月17日 Dry beneficiation is generally used to process bentonite with better raw ore quality, or bentonite-rich ore with montmorillonite content of more than 80%.This method is to dry the raw ore in the sun, air dry it naturally or dry it in the oven. It is first crushed manually or with a jaw crusher, and then crushed with a Raymond mill and other roll mills

获取价格