منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

iron ore crushed

Crushed Ores Create Wiki Fandom

Handheld Blockzapper. Shadow Steel Tools. Categories. Community content is available under CC-BY-SA unless otherwise noted. Crushed Ores are obtained from crushing

获取价格

进一步探索

What's up with these crushed ores? : r/CreateMod - RedditMinecraft Create Mod Tutorial - Ore Processing System Ep 30

Mineral processing - Wikipedia

Mineral processing is the process of separating commercially valuable minerals from their ores in the field of extractive metallurgy. Depending on the processes used in each instance, it is often referred to as ore dressing or ore milling. Beneficiation is any process that improves (benefits) the economic value of the ore by removing the gangue minerals, which results in a higher grade product (ore concentrate) and a waste stream (

获取价格

Comminution and classification technologies of iron ore

2022年1月1日 Iron ore crushing and screening. Iron ore is one of the main raw materials to make steel. About 98% of the mined iron ore is used to make steel either by the blast

获取价格

Iron ore BHP

The crushed ore is sorted over screens and resized to different specifications, such as lump and fines products. Once the iron ore is processed, a stacker builds a stockpile in the stockyards. When ready for transportation, a reclaimer picks up the ore from the stockpiles and conveys it to train load out facilities.

获取价格

The six main steps of iron ore processing - Multotec

When iron ore is extracted from a mine, it must undergo several processing stages. Six steps to process iron ore. 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing.

获取价格

Iron processing - Ores, Smelting, Refining Britannica

Crushing. As-mined iron ore contains lumps of varying size, the biggest being more than 1 metre (40 inches) across and the smallest about 1 millimetre (0.04 inch). The blast furnace, however, requires lumps between 7 and 25 millimetres, so the ore must be crushed to reduce the maximum particle size. Crushed ore is divided into various fractions ...

获取价格

Iron Ore Crushed - Captain of Industry Wiki

Iron Ore Crushed. This article is a stub. You can help Captain of Industry Wiki by expanding it. Iron Ore Crushed is a semi-processed loose material which is used in the late-game in the production of Iron and therefore Steel. It is created by processing Iron Ore in a Crusher and is used in both the Blast Furnace II and Arc Furnace II .

获取价格

A Mine-to-Crusher Model to Minimize Costs at a Truckless Open-Pit Iron

2022年8月18日 Innovation has an important role in improving the productivity, safety and sustainability of mining operations. Historically, ore transport was done by diesel trucks, but with the commitment to reduce CO2 emissions and increase mine safety, mining companies have invested in innovative, more sustainable ore transport technologies. The innovative

获取价格

Hematite: A primary ore of iron and a pigment mineral - Geology

Hematite is the most important ore of iron, and it has been used by people as a pigment for at least 40,000 years. Learn about the uses and properties of the mineral hematite. ... The crushed coal, which has a very low specific gravity, is placed on the heavy liquid and the light clean coal floats, while high-specific-gravity impurities such as ...

获取价格

Damage evaluation of concrete using iron ore tailings as

2023年3月7日 Using iron ore tailings (IOTs) as the main aggregate for concrete will not only save crushed stone mining but will also reduce the environmental impact of IOTs. A discrete element model of concrete with realistic IOTs shape was developed using particle flow coding 3D technique. The accuracy of the numerical model was verified with the

获取价格

Iron Mining Process - Minnesota Iron

Crushing At the processing plant, the taconite is crushed into very small pieces by rock crushing machines. The crushers keep crushing the rock until it is the size of a marble. The rock is mixed with water and ground in rotating mills until it is as fine as powder. Separation The iron ore is separated from the taconite using magnetism.

获取价格

How iron ore is crushed? - LinkedIn

2023年3月13日 Iron ore is a mineral that is found in rocks and minerals from which metallic iron can be extracted. The crushing process is an essential step in the production of iron ore, as it prepares the ore ...

获取价格

Collections: Iron, How Did They Make It? Part I, Mining

2020年9月18日 Iron ore, even crushed, is terribly heavy and bulk and as we’ll see next week, the ratio of metal to useless rock really favors useless rock. Consequently, if you could do the entire smelting process at the mine, you did, rather than transport so much of that useless rock far away only to have it turned into slag there.

获取价格

Create VS. Tinkers /// 1 stack of iron ore Crushing wheel+fans VS ...

Tinkers /// 1 stack of iron ore Crushing wheel+fans VS. Smeltery. Yes but can Tinker's create Gravel + Sand + Flint + Red Sand + Gold + Iron + Terracotta + Clay + Concrete + Glass all out of just Cobblestone? lol all jokes aside I love the combo of Tinkers+Create. Been running a server with that combo for a while now.

获取价格

Bobs/Angel's ore Refining for beginners : r/factorio - Reddit

You need 3 crushed saph to make 2 iron plates. So here, you have a net 4 saph ore (needs 2 to crush) to 2 iron plate ratio. Adding sorting turns into this: 2 ore -> crush = 2 crushed ore. 4 crushed ore -> sort = 2 iron ore, 1 copper ore. Smelting non-crushed ore is a 1:1 ratio, so you get 2 iron plates and 1 copper plate out of this.

获取价格

Bulk Products, Athens TX, Tyler TX, East Texas Splawn Sales

1½" CRUSHED LIMESTONE $85.00/yard. BIN #6 1½" Crushed Limestone $85.00/yard. BIN #7 Masonry Sand $50.00/yard. BIN #8 Decomposed Granite $100.00/yard. BIN #9 Bedding Soil ... Crushed Iron Ore Road Base $50.00/yard. BIN #18 4-8" Colorado Creek Rock $350.00/yard. BIN #19 2-4" Colorado Creek Rock $350.00/yard. BIN #20 2"

获取价格

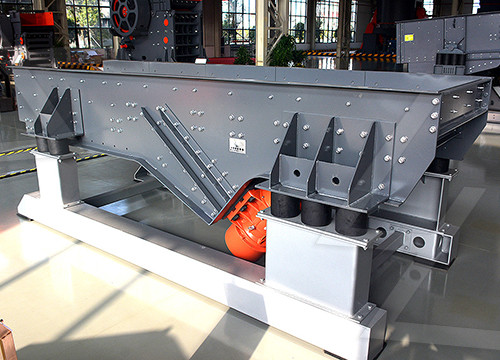

Iron ore crushing and screening process - SBM Ultrafine Powder

2022年8月3日 2. Iron ore screening process: Iron ore screening equipment generally uses a circular vibrating screen to screen the materials after the second crushing. Generally, materials with a size of 10mm or less can be screened for dry selection. After screening, materials with a size of 10-40mm enter the fine crusher for fine crushing.

获取价格

Create VS. Tinkers /// 1 stack of iron ore Crushing wheel+fans VS ...

Tinkers /// 1 stack of iron ore Crushing wheel+fans VS. Smeltery. Yes but can Tinker's create Gravel + Sand + Flint + Red Sand + Gold + Iron + Terracotta + Clay + Concrete + Glass all out of just Cobblestone? lol all jokes aside I love the combo of Tinkers+Create. Been running a server with that combo for a while now.

获取价格

Bobs/Angel's ore Refining for beginners : r/factorio - Reddit

You need 3 crushed saph to make 2 iron plates. So here, you have a net 4 saph ore (needs 2 to crush) to 2 iron plate ratio. Adding sorting turns into this: 2 ore -> crush = 2 crushed ore. 4 crushed ore -> sort = 2 iron ore, 1 copper ore. Smelting non-crushed ore is a 1:1 ratio, so you get 2 iron plates and 1 copper plate out of this.

获取价格

Bulk Products, Athens TX, Tyler TX, East Texas Splawn

1½" CRUSHED LIMESTONE $85.00/yard. BIN #6 1½" Crushed Limestone $85.00/yard. BIN #7 Masonry Sand $50.00/yard. BIN #8 Decomposed Granite $100.00/yard. BIN #9 Bedding Soil ... Crushed Iron Ore Road

获取价格

Iron ore crushing and screening process - SBM Ultrafine Powder

2022年8月3日 2. Iron ore screening process: Iron ore screening equipment generally uses a circular vibrating screen to screen the materials after the second crushing. Generally, materials with a size of 10mm or less can be screened for dry selection. After screening, materials with a size of 10-40mm enter the fine crusher for fine crushing.

获取价格

COMMON IRON ORE CRUSHING AND SCREENING PROCESS

2021年6月25日 In medium and small iron ore concentrators, two-stage crushing processes are generally used. This process can be used when the size of the raw ore is small or the required crushing is small.

获取价格

Comparison on micromechanical properties of interfacial

2021年10月15日 Iron ore tailings (IOTs), as a waste from the mining and mineral industry (Osinubi et al., 2015), can be an ideal candidate for aggregate in this concern. IOTs were generated during the removal of overburden for ore with a waste-to-ore ratio (stripping ratio) that varies from 2:1 to 5:1 ( Yellishetty et al., 2008 ) or 2.5:1 to 3:1 ( Ma et al ...

获取价格

Energy and Environmental Profile of the U.S. Mining

The crushing stages will reduce the iron ore from several feet in diameter at the primary stage to six inches down to one-half or three-eighths of an inch as a final product. The crusher product is fed to the milling operation for further size reduction. 4.1.2.2 Grinding

获取价格

Iron Ore - Eco - English Wiki

2024年1月2日 Iron Ore is a resource that can be gathered with any pickaxe from iron ore veins, which are found within Sandstone. WiKi. ECO. Eco site. Eco on Steam. Eco Discord. Eco Mods. ... Crushed Iron Ore x2 Crushed Sandstone x1 Iron Ore x12 Mining Level 1 2 50 0.5 Jaw Crusher. Crushed Iron Ore x5 Iron Ore x20 Mining Level 1 0.5 90 0.5

获取价格

Crushing characteristics and performance evaluation of iron ore

2023年12月1日 1. Introduction. Due to the decreasing reserves of high-grade iron ore and secondary resources used for steelmaking, it has become an important research and development area to improve the grade of iron ore through crushing (Gul et al., 2014).The quality of iron ore crushing directly affects the performance of pellets and sinter, so as to

获取价格

BULK MATERIAL DENSITY TABLE - Tapco, Inc

Copper Ore 120-150 Copper Ore, Crushed 100-150 Copper Sulfate (Bluestone) 75-85 Copperas (See Ferrous Sulfate)-Copra Cake, Ground 40-45 Copra Cake, Lumpy 25-30 Copra, Lumpy 22 ... Iron Ore, Concentrates 120-180 Iron Ore, Crushed 135-150 Iron Oxide, Pigment 25 Iron Oxide, Mill Scale 75

获取价格

Iron Ore: From Mining to Processing to Dust Control

Blasting iron ore deposits and processing crushed iron-rich minerals creates a lot of hazardous dust. Controlling that dust is important for efficiency and worker safety. ... Iron ore is a rock or mineral from which metallic iron can be extracted economically. It constitutes 5% of the earth’s crust.

获取价格

From mine to part: directed energy deposition of iron ore

2021年7月19日 After mining, iron ore undergoes crushing, magnetic separation of large impurities, concentration and pelletisation to increase its iron content. In this present work, waste collected during the pelletisation process starting with the magnetite ore at LKAB, Sweden ( LKAB Sweden, 2019 ), was used as feedstock material in laser DED.

获取价格

Mineral processing - Wikipedia

Crushing, a form of comminution, one of the unit operations of mineral processing. Mineral processing is the process of separating commercially valuable minerals from their ores in the field of extractive metallurgy. Depending on the processes used in each instance, it is often referred to as ore dressing or ore milling.. Beneficiation is any process that

获取价格

Bulk Material Densities Ross Manufacturing

50 - 65. Lead Oxide (Red Lead) 100 Mesh. 30 - 150. Alumina, Sized or Briquette. 65. Lead Oxide (Red Lead) 200 Mesh. 30 - 180. Aluminum Chips, Oily. 7 - 15.

获取价格