مسكن

>

working principles of ring roll mill

مسكن

>

working principles of ring roll mill

منتج

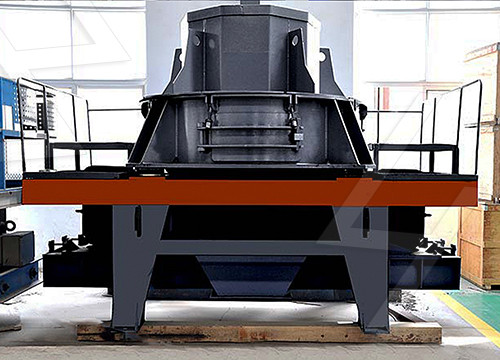

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

working principles of ring roll mill

Roller Mill - Springer

ring type, etc. Working principle: the motor drives the grind-ingtabletorotatethroughthereducer,thematerial falls into the center of the grinding table from the feed inlet through the air lock feeder, and the hot air enters the mill

获取价格

进一步探索

Basic specifications of the rolling mill. Download Table - (PDF) Design and Realization Of Roller Mill Control Rolling Mills: 6 Different Types of Rolling Mills [Images VERTICAL ROLLER MILL OPERATION PARAMETERS - Types of Rolling mills – With detailed information

The Ring Rolling Mill: Performance, Principles, and Applications

2023年8月8日 The working principle of the Ring Rolling Mill is based on a process that combines pressure and heat to shape and modify metal materials. By preheating the

获取价格

Precision ring rolling technique and application in high

Forming principle of ring rolling: a) CRR; b) vertical HRRR; c) horizontal HRRR; d) HRARR. low productivity, coarse and uneven microstructures, incomplete metal

获取价格

Rolling (metalworking) - Wikipedia

Roll bending produces a cylindrical shaped product from plate or steel metals . Roll forming, roll bending or plate rolling is a continuous bending operation in which a long strip of metal (typically coiled steel) is passed through consecutive sets of rolls, or stands, each performing only an incremental part of the bend, until the desired cross-section profile is obtained. Roll forming is ideal for prod

获取价格

Introduction to Rolling Process - Cambridge University Press

2 Principles and Applications of Metal Rolling (ii) Shape of the rolled product- flat, sections or hollow sections rolling. (iii) Direction of rolling- lengthwise, transverse, and skew rolling.

获取价格

Principles and Applications of Metal Rolling

4.1.1 Rolling mill rolls 169 4.1.2 Roll neck bearings 186 4.1.3 Roll chocks 197 4.1.4 Mill housings 201 4.1.5 Mechanisms for roll adjustment and roll balance 205 4.1.6 Roll

获取价格

Introduction to Rolling Process (Chapter 1) - Principles

2016年6月5日 Rolling is the most important metal forming process. More than 95% of ferrous and non-ferrous metals and alloys are processed to their usable shapes by rolling. Usable shapes of rolled metals are plate,

获取价格

RLM Ring Roller Mill working principle - ALPA - YouTube

2019年7月18日 Relying on the grinding roller orbital revolution and rotation on the grinding ring track to finish grinding.Built-in classifying wheel, available D50:2~45...

获取价格

Raymond® Roller Mill air-swept vertical ring-roll - Schenck Process

The Raymond ® Roller Mill is an air-swept vertical ring-roll mill with an integral classification system that simultaneously dries, pulverizes and classifies a number of

获取价格

Rolling Equipment and Systems (Chapter 4) - Principles and

2016年6月5日 Summary. Various types of equipment and systems are used in a rolling mill. The major equipment is obviously the mill stand in which the material is actually

获取价格

Rolling Process: Definition, Working Principle,

2020年7月22日 Rolling is a metalworking process to reduce the thickness of the metal sheet with the help of rollers. The metal sheet is passed through rotating rollers which puts pressure on the sheet. When that pressure

获取价格

Working Principle Of Bead Mill - ELE Mechanical

2019年6月20日 The direct grinding area of bead mill is grinding chamber, which contains agitator turned by rotating shaft (spindle). The chamber space is mostly filled with grinding media and the material leakage is

获取价格

Vertical roller mill - Wikipedia

The vertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, slag and coal slag. It has the benefits of simple structure and low cost of manufacture and use. Vertical roller mills have many different forms, but they work basically the same. All of these forms come with a roller (or the equivalent of roller ...

获取价格

What Is A Rolling Mill? Metal Processing Machinery

What Is A Rolling Mill? In metalworking, rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness and to make the thickness uniform. The concept is similar to the rolling of dough. Rolling is classified according to the temperature of the metal rolled. If the temperature of the ...

获取价格

Roller Mill SpringerLink

2023年7月4日 Roller Mill. Roller mill is a type of grinding equipment for crushing materials by pressure between two or more rolling surfaces or between rolling grinding bodies (balls, rollers) and a track (plane, ring, and table). The roller mill with several grinding rollers as working components rolls along the grinding ring or the grinding table to ...

获取价格

An innovative spinning-rolling process and its ... - ScienceDirect

2022年12月1日 Aiming at the challenges for manufacturing the big-tapered profiled ring disk, this work proposes an innovative spinning-rolling process based on the typical ring rolling mill. By intelligent FE modelling simulations and experiment, the proposed new process is deeply investigated. The following conclusions can be drawn: (1)

获取价格

Rolling Process: Definition, Working, Applications, Defects, Type

2020年3月19日 Working Principle of Rolling Process: ... The rolls are rotating in opposite directions. In this mill, between the first and the second rolls, the material passes. If the second roll rotates in one direction then the bottom roll rotates in another direction. The material is rolled both forward and returns in three high-rolling mills.

获取价格

Introduction to Rolling Process - Cambridge University Press

2 Principles and Applications of Metal Rolling (ii) Shape of the rolled product- flat, sections or hollow sections rolling. (iii) Direction of rolling- lengthwise, transverse, and skew rolling. (iv) Mode of rolling mill operation- continuous (unidirectional), and reverse rolling, where direction of rotation of rolls are reversed. When two rolls of equal diameter and with axis

获取价格

Numerical Modelling and Simulation of Radial-Axial Ring

2011年9月9日 The involved key technologies for the FE modelling of radial-axial ring rolling process mainly include geometry and assembly model, mesh design and optimization, material model, model of guide rolls control mechanism, contact and friction, and determination of the paths of the rolls. 3.1.1. Geometry and assembly model.

获取价格

Energy-Efficient Technologies in Cement Grinding IntechOpen

2016年10月5日 In this chapter an introduction of widely applied energy-efficient grinding technologies in cement grinding and description of the operating principles of the related equipments and comparisons over each other in terms of grinding efficiency, specific energy consumption, production capacity and cement quality are given. A case study performed

获取价格

Main Features of a Modern Wire Rod Mill – IspatGuru

2014年1月3日 The objective of a wire rod mill (WRM) is to reheat and roll steel billets into wire rods. Wire rods are normally rolled in a high-speed rolling mill, where steel temperature is above 1,000 deg C, maximum speed of rolling can go up to 140 metres per second (m/s) and coils of wire rod produced can be up to 2.5 tons of weight and up to 10 ...

获取价格

What is Rolling Mills and Their Types? - Engineering Choice

2021年9月24日 Types of Rolling Mills. As per the requirement of the process and arrangement of the rolls, the rolling mill rolls can be divided into the following categories: 1. Two High Rolling Mills. It consists of two rollers, which rotate in the opposite direction for the desired movement of the workpiece. The workpiece is fed between the rollers, which ...

获取价格

Introduction to Rolling Process (Chapter 1) - Principles and ...

2016年6月5日 Rolling is the most important metal forming process. More than 95% of ferrous and non-ferrous metals and alloys are processed to their usable shapes by rolling. Usable shapes of rolled metals are plate, sheet, strip, foil, different sections like rail, beam, channel, angle, bar, rod, and seamless pipe, etc., as shown in Fig. 1.1 and Fig. 1.2.

获取价格

A comprehensive review on incremental deformation in

2022年2月15日 Flat rolling. Flat rolling [] is one of the most basic forms of rolling and it is extensively used to produce flat sheets and strips.As depicted in the book, “Cold Rolling of Steel” [], it was first used by Leonardo Da Vinci to roll lead by employing a hand-cranked mill.Even after several decades since its introduction, the fundamentals of rolling for the

获取价格

Main Features of a Modern Wire Rod Mill – IspatGuru

2014年1月3日 The objective of a wire rod mill (WRM) is to reheat and roll steel billets into wire rods. Wire rods are normally rolled in a high-speed rolling mill, where steel temperature is above 1,000 deg C, maximum speed of rolling can go up to 140 metres per second (m/s) and coils of wire rod produced can be up to 2.5 tons of weight and up to 10 ...

获取价格

What is Rolling Mills and Their Types? - Engineering Choice

2021年9月24日 Types of Rolling Mills. As per the requirement of the process and arrangement of the rolls, the rolling mill rolls can be divided into the following categories: 1. Two High Rolling Mills. It consists of two rollers, which rotate in the opposite direction for the desired movement of the workpiece. The workpiece is fed between the rollers, which ...

获取价格

Introduction to Rolling Process (Chapter 1)

2016年6月5日 Rolling is the most important metal forming process. More than 95% of ferrous and non-ferrous metals and alloys are processed to their usable shapes by rolling. Usable shapes of rolled metals are plate,

获取价格

A comprehensive review on incremental deformation in

2022年2月15日 Flat rolling. Flat rolling [] is one of the most basic forms of rolling and it is extensively used to produce flat sheets and strips.As depicted in the book, “Cold Rolling of Steel” [], it was first used by Leonardo Da Vinci to roll lead by employing a hand-cranked mill.Even after several decades since its introduction, the fundamentals of rolling for the

获取价格

Tube and Pipe Rolling SpringerLink

2022年12月27日 The main rolling mill of the automatic plug mill is the two-high irreversible longitudinal rolling mill. Behind the working roll, there is a rolling mill equipped with a pair of reverse rolls rotating at high speed reversely. The rolled pipe is delivered back to the front stage automatically by reverse rolls.

获取价格

Rolling (metalworking) - Wikipedia

Rolling schematic view Rolling visualization. In metalworking, rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness, to make the thickness uniform, and/or to impart a desired mechanical property. The concept is similar to the rolling of dough.Rolling is classified according to the

获取价格

Centrifugal attrition mills - Chemical Engineering - Beyond Discovery

2023年9月24日 The Lopulco mill or ring-roll pulveriser. These mills are manufactured in large numbers for the production of industrial minerals such as limestone and gypsum. A slightly concave circular bull ring rotates at high speed and the feed is thrown outwards by centrifugal action under the crushing rollers, which are shaped like truncated cones, as ...

获取价格

How Does The Raymond Roller Mill Work? - YouTube

观看视频1:192022年3月30日 Raymond roller mill is used for getting coarse powder. It is widely used in grinding calcite, limestone, talc, kaolin and other non-flammable and explosive m...

获取价格

VERTICAL ROLLER MILLS - AMCL

UBE Mills are energy efficient and easy to operate maintain. The Mills are available in wide range of capacity for all the applications. UBE has been pioneers in cement and slag grinding where “2-Way System” is applied to allow highly efficient grinding while maintaining vibration kept at minimum level. M/s.

获取价格

Rod Mills - 911 Metallurgist

2016年5月31日 Mill discharge is generally less than 5% + 4 mesh in wet open circuit operations, for dry grinding work reduce the capacities indicated by approximately 30% to 50%. Rod Mill Working Principle Components. A Rod Mill has for Working Principle its inside filled grinding media, in this case STEEL RODS. These rods run the length of the

获取价格

Everything you need to know about rolling process

Two-high rolling mills; Three-high rolling mills; Four-high rolling mills; Tandem rolling mills; Cluster rolling mills; Rolling lubrication: As friction occurs between the rolls and metal during the rolling process, lubrication plays a very important role. The friction is also useful as it is responsible for shifting the work forward between ...

获取价格

Introducing cold pilger mill technology - The Fabricator

2006年7月11日 Cold pilgering is a longitudinal cold-rolling process that reduces the diameter and wall thickness of metal tube in one process step. Depending on the material, the cold pilger process achieves cross-section reductions of more than 90 percent in a single working cycle. Figure 1. The cold pilgering process relies on four main actions: The tube ...

获取价格

Raymond® Roller Mill air-swept vertical ring-roll - Schenck Process

The Raymond ® Roller Mill is an air-swept vertical ring-roll mill with an integral classification system that simultaneously dries, pulverizes and classifies a number of different types of products including limestone, clay, minerals and others. From a feed ranging in size from approximately. ½ -2in / 10-50mm, the roller mill can produce ...

获取价格

Features and working principle of six-high rolling mill

2022年6月2日 2 The working principle of a six-high rolling mill. The disadvantage of the four-high mill is that the contact area between the work roll and the backup roll is larger than the width of the rolling strip. No matter how large the diameter of the backup roll is, the rolling load will increase the radius of the work roll, as shown in Figure 4.

获取价格