مسكن

>

Motor For Crusher In Cement Plant In Romania

مسكن

>

Motor For Crusher In Cement Plant In Romania

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

Motor For Crusher In Cement Plant In Romania

Selection of AC Induction Motors for Cement Plant Applications

In cement plants, proper specification and supply of AC induction motors is critical to project schedules and providing efficient production. This paper focuses on the selection

获取价格

进一步探索

IEC Quick Reference Chart James ElectricThe IEC standard for AC Motors ~ Learning Electrical

Romania CRH

CRH is one of the largest cement producers in Romania. Our Romanian operations comprise two cement plants, a grinding station and an extensive network of cement

获取价格

进一步探索

CRH Ciment Romania becomes ROMCIM - ROMCIM Romania - Cement industry news from Global Cement

Cement Plants located in Romania - The Global Cement Report

Switch to statistics view. Cement plant locations and information on Romania can be found below. For full access to the database, purchase The Global Cement Report™, 15th

获取价格

Low-voltage squirrel cage motors for cement plants

1400 kW low-voltage squirrel cage motor for cement plant. For a large cement plant, we recently delivered a 1400kW low-voltage squirrel cage

获取价格

Considerations in the Selection and Application of AC and DC

2009年5月29日 There are several types of motors to choose from when selecting motors for large HP (2000 HP - 10.000 HP) cement plant applications including; squirrel cage

获取价格

ABB motors for the cement industry

Motors for the cement industry Reducing operating costs in harsh conditions demands efficient and reliable process equipment. Most processes in the cement industry include applications in extreme

获取价格

Low voltage AC drives Complex cement challenges made

new deposit some 2,642 meters from the crusher on the hill top to its factory in the valley below. The aim is to save energy while using as few conveyors and transfer stations as

获取价格

Crusher, Crushing plant - All industrial manufacturers

Motor power: 220 kW - 550 kW. Weight: 12 t - 50 t. ... single-cylinder hydraulic cone crusher is designed with a perfect combination of crushing stroke, crushing speed and

获取价格

Cement Plant Crushers Manufacturers Jaw Crushers Roller

Ashoka Group Manufacture and Supply all type of cement plant equipment. We manufacture and supply all type of Grinding and Crushing equipment. Hammer Crusher

获取价格

The essentials of electrical systems in cement plants

2023年4月2日 In this technical article electrical systems in cement plant will be touched upon. All machines are driven by electric motors. Majority of the motors are 400- 440 volts. A selected few motors of higher ratings

获取价格

Modeling of energy consumption factors for an industrial cement ...

2022年5月9日 Database. The provided data were collected from a cement plant (Fig. 1) located in Ilam, west of Iran.The plant has two cement production lines which in total produces 5300 t/day cement.

获取价格

Choosing a mobile impact crusher for recycling –

2021年3月12日 Impact crushers are very good at liberating scrap iron from concrete." Matching growth in the contractor/rental market. Stephen Whyte, product manager, mobile product development, KPI-JCI Astec Mobile

获取价格

Finding failure - International Cement Review

2017年9月6日 Finding failure. Roller presses are a popular choice for raw, pre-clinker or finish grinding. Online condition monitoring of its components can help detect early equipment failure and reduce downtime of the grinding section. By Dalog Diagnosesysteme GmbH, Germany. Roller presses have proven to be a popular option for new and old

获取价格

Cement Plants located in Romania - The Global Cement Report

Switch to statistics view. Cement plant locations and information on Romania can be found below. For full access to the database, purchase The Global Cement Report™, 15th Edition. Purchase. Summary. Cement capacity (Mt) Integrated plants. 7.

获取价格

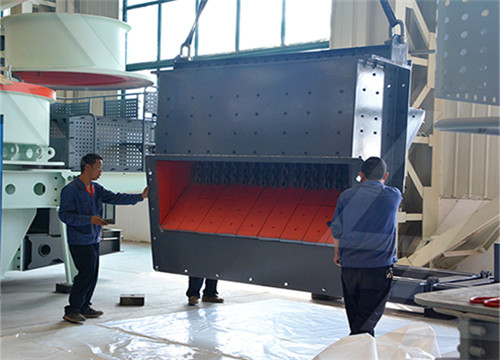

Hammer Crusher Machine Hammer Crusher Cement Crusher

Cement hammer crusher machine is made up of box, rotor, hammer, impact plate, sieve plate and other parts. The main working part of hammer cement crusher is a rotor with a hammer, also known as hammer head. The material is beaten, impacted, sheared and grinded by the hammer moving at high velocity. At the bottom of rotor, there is a screener ...

获取价格

Long-lasting roller crusher and sizer solutions I

Robust roller crusher and sizer offering to maximise your crushing capabilities. Our roller crushers and sizers are built to last, with strong frames and self-lubrication systems to reduce your maintenance burdens. They offer reliable crushing of materials in the cement and mining industry, including highly-abrasive and sticky ones, and ...

获取价格

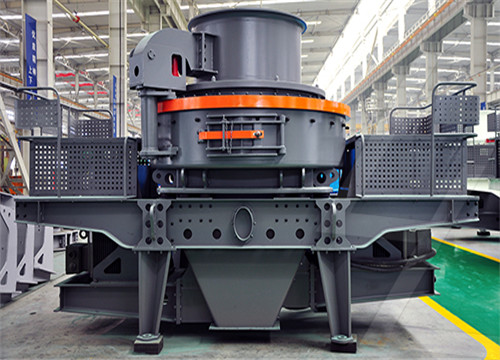

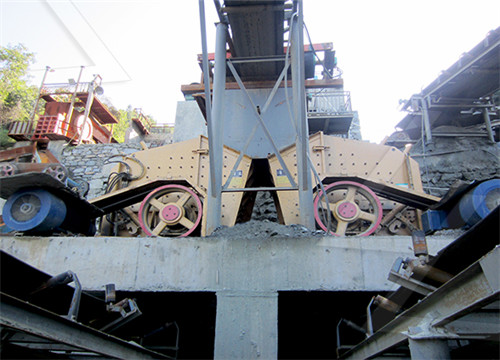

Cement Crusher Crushers for Cement Plant AGICO Cement

Cement Manufacturing Equipment. Cement Crusher. Crusher is a kind of machinery that is widely used in the cement production industry. It is mainly used in the material preparation process to crush the raw materials into proper size particles. AGICO offers 4 types of crushers for cement plants: hammer crusher, jaw crusher, impact crusher, and ...

获取价格

Predictive Maintenance for Cement Industry - A Complete Guide

2022年3月3日 It has witnessed unparalleled growth at the heart of most economic developments and international growth this decade. Fortune Insights report says, the global cement market will grow from $326.80 billion in 2021 to $458.64 billion in 2028, a steep 5.1% globally. It is then no wonder that cement plants face pressure for process and

获取价格

Selecting the right crusher for your operations - Quarry

2020年3月19日 Best suited for secondary crushing applications, cone crushers are designed to crush pre-sized materials, usually 100mm, 150mm or 200mm, depending on the size of the crusher. Cone crushers can form finished products down to 12mm or less. Like the jaw crusher, the cone crusher provides a relatively low cost crushing solution, but

获取价格

Crushing Machines Plants at Best Price in India

Concrete Waste Crushing Machine, 3 Phase 12.5 HP. ₹ 2,50,000 Get Latest Price. Capacity: 1000 kg to 1500 kg Per hour. Power: 3 Phase 12.5hp. Crushing chamber size: 800mm x 800mm x 700mm. Main Base Crusher plate: 20mm Thick with Bolting Arrangement for Easy Replacemen. Max Input size: 400mm x 200mm x 200mm.

获取价格

ENERGY STAR Guide for the Cement Industry

(e.g. 50 years or longer). There were 110 operating cement plants in the U.S. in 2010, spread across 37 states and Puerto Rico. Portland and blended cement was produced at 110 plants in 2010, while masonry cement was produced at 71 plants. Clinker was produced at 100 plants (102 including Puerto Rico) in the U.S. in 2010.

获取价格

Chapter 4 Cement Manufacturing and Process Control

The cement is now ready for use in construction projects. The flow sheet of cement manufacturing is given in Fig. 4.1. Kiln feed is subjected to succes-sive physical and chemical reactions as its temperature rises gradually as shown in Table 4.1. 4.2 Raw Material The major raw materials used as a source of CaO for cement manufacturing are

获取价格

Raw mill - AGICO Cement Plant

cement ball mill. Application: limestone, clay, coal, feldspar, calcite, talc, iron ore, copper, phosphate, graphite, quartz, slag. Capacity: 0.65-615T/H. The cement ball mill usually can be applied to raw meal grinding or cement grinding. Besides, the cement ball mill also can be used for metallurgical, chemical, electric power, other mining ...

获取价格

Crushing Machines Plants at Best Price in India

Concrete Waste Crushing Machine, 3 Phase 12.5 HP. ₹ 2,50,000 Get Latest Price. Capacity: 1000 kg to 1500 kg Per hour. Power: 3 Phase 12.5hp. Crushing chamber size: 800mm x 800mm x 700mm. Main Base Crusher plate: 20mm Thick with Bolting Arrangement for Easy Replacemen. Max Input size: 400mm x 200mm x 200mm.

获取价格

ENERGY STAR Guide for the Cement Industry

(e.g. 50 years or longer). There were 110 operating cement plants in the U.S. in 2010, spread across 37 states and Puerto Rico. Portland and blended cement was produced at 110 plants in 2010, while masonry cement was produced at 71 plants. Clinker was produced at 100 plants (102 including Puerto Rico) in the U.S. in 2010.

获取价格

Chapter 4 Cement Manufacturing and Process Control

The cement is now ready for use in construction projects. The flow sheet of cement manufacturing is given in Fig. 4.1. Kiln feed is subjected to succes-sive physical and chemical reactions as its temperature rises gradually as shown in Table 4.1. 4.2 Raw Material The major raw materials used as a source of CaO for cement manufacturing are

获取价格

Raw mill - AGICO Cement Plant

cement ball mill. Application: limestone, clay, coal, feldspar, calcite, talc, iron ore, copper, phosphate, graphite, quartz, slag. Capacity: 0.65-615T/H. The cement ball mill usually can be applied to raw meal grinding or cement grinding. Besides, the cement ball mill also can be used for metallurgical, chemical, electric power, other mining ...

获取价格

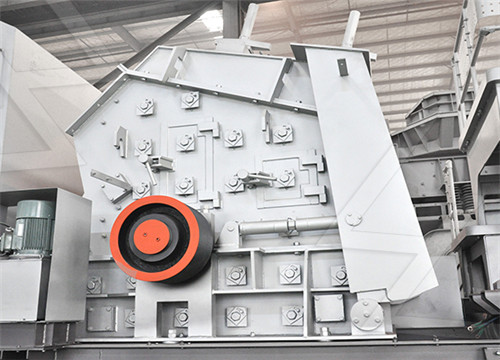

Impact Crusher - Impact Rock Crusher AGICO Cement Plant

What Is Impact Crusher. Impact crusher is a kind of crushing machine which uses impact energy to break materials. It is suitable for handling brittle materials of medium hardness with side length not exceeding 500mm and compressive strength not exceeding 350 mpa. The impact machine has the characteristic of large crushing ratio, low energy ...

获取价格

Pugmills - Astec

Astec pugmills and pugmill plants provide portability with an aggressive mixing action. The continuous-mix plants include two counter-rotating shafts with paddles and timing gears to keep the mix moving at the optimal speed for the best-quality mix. Controlled blending and automatic proportioning ensure the consistent end product your operation ...

获取价格

News Constmach Concrete Plants Crushers

The crusher consists of 132 Kw motor. The crusher will be installed by CONSTMACH supervisors in upcoming days. 25.09.2020. ... We would like the share our happiness of installing our 10th concrete plant in ROMANIA! MOBICOM 45 is equipped with 1 set 50 tonnes capacity cement silo. The plant is installed, trial production is done and operator

获取价格

EV hammer impact crusher -

The crushing process Most cement plants these days extract limestone by blasting. This produces many oversize boulders which often contain a lot of clay and sand. The crusher therefore has to handle feed containing fairly large blocks as well as some sticky materials. The proven and reliable EV hammer impact crusher is a cost-

获取价格

Jaw Gyratory Crusher Pro

The Jaw Gyratory Crusher Pro is engineered to handle bigger chunks of material than comparable gyratory crushers of the same mantle diameter. This gives you greater flexibility in your crushing operation, and reduces the tendency for bridging in the feed zone. Despite being capable of handling large feed materials, the Jaw Gyratory Crusher Pro ...

获取价格

The Cement Plant Operations Handbook - International

1. The basics of cement manufacture – 2. History of cement manufacture – 3. Portland cement in today’s world 2. Raw materials management system – 22. Concrete problems 16 1. Raw materials – 2. Raw mix – 3. Reserves – 4. Crushing – 5. Drying – 6. Pre-blending – 7. Storage and handling 3. Raw milling and blending 3.

获取价格

Cement Manufacturing Process Phases Flow Chart Cement

2012年8月30日 Cement Manufacturing Process Phase 1: Raw Material Extraction. Cement uses raw materials that cover calcium, silicon, iron and aluminum. Such raw materials are limestone, clay and sand. Limestone is for calcium. It is combined with much smaller proportions of sand and clay. Sand clay fulfill the need of silicon, iron and

获取价格

Jaw Crusher For Sale Jaw Crusher Jaw Crusher Manufacturer

The jaw crusher is suitable for crushing various ores or rocks with a compressive strength limit below 250 MPa. Widely apply for mining, cement and concrete industries. It is mainly used as coarse crusher and medium crusher in mines, building materials and infrastructure. The jaw cement crusher produced by AGICO Cement has the

获取价格

Tramp Metal Detection - Advancing Mining - Thermo Fisher

2022年9月27日 Tramp metal detection provides an economical and reliable means to protect crushers, conveyors and other processing equipment; assuring continuous and uninterrupted operation at your cement plant. A reliable tramp metal detection system not only protects your equipment, but your workers as well. Tramp metal detection systems

获取价格

LT CRUSHING SOLUTIONS – LT Construction Mining

Salient Features. Large capacity range. Custom made plant layouts to meet site specific requirements. Rugged design proven technology. Operation Successfully in Various mineral application. Limestone Crushing Plant supplied to all Cement Plants. Standard Attachments. Apron Feeder. Wobbler Feeder.

获取价格