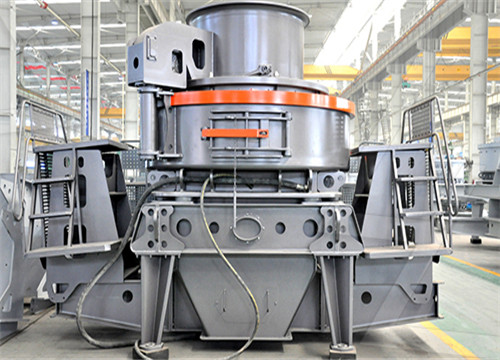

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

sag ball consists

SAG Mill Grinding Circuit Design - 911 Metallurgist

2016年6月6日 SAG circuits are common in the industry based on: High single-line capacities (leading to capital efficiency) The ability to mill a

获取价格

A Comprehensive Guide to SAG Mill Operation - ball mills supplier

A SAG mill consists of a rotating drum filled with steel balls or rods, and the rock that needs to be ground. The drum is mounted on a stationary structure, which houses the motor,

获取价格

进一步探索

Schematic diagram of AG/SAG mill process mechanisms (PDF) Operation Analysis of a SAG Mill under Different ... -

SAG Mill Ball Sizing - Grinding Classification Circuits ...

The question how the space between steel ball and ore/rock particle is filled in the mill depends on the size distribution of the feed material and steel ball .For the optimal

获取价格

AMIT 135: Lesson 6 Grinding Circuit – Mining Mill Operator Training

Mill (grinding) - Wikipedia

SAG mill. SAG is an acronym for semi-autogenous grinding. SAG mills are autogenous mills that also use grinding balls like a ball mill. A SAG mill is usually a primary or first stage

获取价格

(PDF) Real-Time Estimation of SAG Mill Charge ... - ResearchGate

2023年10月2日 Hatch Ltd. Brisbane Abstract Control of the total charge and the ball charge volume is vital to the optimum performance of semi-autogenous grinding (SAG)

获取价格

SAG Balls Molycop

The Molycop range of SAG (semi-autogenous grinding) balls is built for impact and superior wear resistance. Through an innovative manufacturing processes Molycop produces a

获取价格

SAG Mill Ball Size Evaluator Evaluation Factors

2013年9月8日 The SAG Mill has a “small” circulation load of oversize given be the 3/8″ trommel screen and the 1/2″ x 1 1/4″ discharge grates. The load of 4″ balls in this SAG is “good” but un-measured. SAG Ball consumption

获取价格

Variable Speed SAG Mill - 911 Metallurgist

2018年9月22日 Table of Contents. The single line grinding circuit at Bond Gold’s Colosseum mine consists of variable speed drive semi-autogenous (SAG) milling and secondary grinding with a fixed speed ball mill. There

获取价格

Definition of Mill Diameter D, Mill Length L, and

Whereas 30 years ago the rule of thumb for designing AG/SAG-Ball mill circuits was to split the total installed motor capacity 50:50 between the AG/SAG and ball mill circuits, Tozlu and Fresko's ...

获取价格

(PDF) Optimization and performance of grinding circuits: the

2020年1月16日 [Show full abstract] (SAG) mill and a ball mill. Currently, the grinding circuits are inefficient in achieving the aspired product fineness of x P 80 = 125 μm even at low to normal throughputs ...

获取价格

Power-based modelling of single-stage AG and SAG mill circuits

other methods. The ball mill correction factor (CFnet) is empirical and one way of estimating it was presented by Amelunxen at the Procemin 2013 Short Course by Doll Amelunxen. The SGI equation uses a transfer size between a SAG and ball mill; it is proposed that a synthetic transfer size of 2100 µm be used to model single-stage SAG mills. 5.9ˇ

获取价格

(PDF) SUPPLY, INSTALLATION, COMMISSIONING OF THE

In June 1998, the world's largest grinding mill, the 40 ft (12.2 m) diameter 20 MW Cadia gearless SAG mill, was commissioned. This was a leap of over 40% above the largest operating SAG mill. A significant saving in capital cost gave the

获取价格

Mineral Processing Exam 2016 Model Answers - Studocu

2010年9月8日 Crusher SAG Ball Mass rate water = 1500 *(1-0)/ /0. = 1400 tph e) Solids content in the ball mill feed will be higher than that in the SAG mill feed. This is because the hydrocyclone acts as a water separator as well as a particle size classifier. The underflow will have a higher solids content than the overflow and so

获取价格

Closed Circuit Grinding VS Open Circuit Grinding - 911

2016年10月12日 Closed Circuit Grinding VS Open Circuit Grinding. The simplest grinding circuit consists of a ball or rod mill in closed circuit with a classifier; the flow sheet is shown in Fig. 25 and the actual layout in Fig. 9. This single-stage circuit is chiefly employed for coarse grinding when a product finer than 65 mesh is not required, but it

获取价格

(PDF) Real-Time Estimation of SAG Mill Charge ... - ResearchGate

2023年10月2日 Abstract. Control of the total charge and the ball charge volume is vital to the optimum performance of semi-autogenous grinding (SAG) mills to maximise throughput and energy efficiency. However ...

获取价格

Semi Autogenous Grinding Mill - an overview - ScienceDirect

Concentrators vary similarly. A new large concentrator unit typically consists of a semi-autogenous grinding mill, high pressure grinding rolls, two ball mills, and a flotation circuit. It can treat up to 170 000 tonnes of ore per day (Sartain, 2010). Larger concentrators consist of multiples of this basic concentrating unit.

获取价格

Semi-autogenous grinding (SAG) mill liner design and development

2007年8月1日 SAG mill liner development draws primarily on practical experience from SAG milling operations supported by computer-based modeling of charge motion in SAG mills and on established good design practice. Liner design needs to respond to the process aspects of mill liner action that are critical to good SAG mill performance, i.e., the impact

获取价格

Ball mill - Wikipedia

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints. Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles ...

获取价格

Mineral Processing Exam 2016.pdf - WhatDoTheyKnow

28 April 2016. 10.00 – 12.00. Answer THREE out of the FOUR questions. Each question carried 25 marks. . Do not answer more than three questions. QUESTION 1 – Comminution. A milling circuit consists of a primary SAG mill that is in open circuit. This is then followed by 2. secondary ball mills in parallel.

获取价格

FULL PRE-CRUSH TO SAG MILLS - ResearchGate

2015年9月20日 grinding mill consists of t wo SAG mills in parallel. The product from each SAG mill re ports to the sump . ... The respective portions report to SAG 1, SAG 2, Ball Mill 1,

获取价格

Optimizing your SAG mill operation - International Mining

2007年3月21日 The mill discharge from these mills consists of slurry, which goes to the ball mills for further grinding, and coarse pebbles/rocks, which are crushed and sent back to the mill. To maximize the capacity of these circuits, the general practice is to use grates with pebble ports (reaching 100 mm) instead of normal grate openings to increase the pebble

获取价格

Achievement of High Energy Efficiency in Grinding Mills at

through grates and screened by a trommel with the oversize being recycled by conveyor back to the SAG mill. Combined product from the SAG mill (trommel undersize) and the Ball mill discharges into a common mill discharge hopper. This product pumped to a set of cyclones with the underflow being directed back to the Ball mill. 30’x 15.4 ’EGL,

获取价格

A Comprehensive Guide to SAG Mill Operation - ball mills supplier

Working Principle of a SAG Mill. The rock and grinding media are placed in the mill and rotated, causing the grinding media to tumble and crush the rock into smaller pieces. The mill operates in a closed circuit with screens that size the ore and send it back to the mill for further grinding. The product from the mill is then sent to a cyclone ...

获取价格

Grinding Circuit - an overview ScienceDirect Topics

The SAG mill trommel undersize is combined with the ball mills’ discharge and pumped to two parallel packs (clusters) of twelve 660 mm diameter cyclones. The cyclone underflow from each line reports to a ball mill, while the cyclone overflow is directed to the flotation circuit. The designed ball milling circuit product is 80% passing 150 µm.

获取价格

Sag Mill Liner Design - 911 Metallurgist

Produced for more than 50 years, effective materials for crushing and. grinding in industry. Consists of martensite matrix, with nickel alloyed at 3-5% in order to. suppress transformation of austenite to pearlite. Chromium usually included between 1.4-4% to

获取价格

Curved Pulp Lifters – Can They Save Energy?

A new plant was commissioned in April 2009. The grinding circuit consists of one semi-autogenous (SAG) mill Ø9.75 m × 4.27 m, two ball mills Ø5.6 m × 7.1 m and a pebble crushing circuit, which is usually called a SAG-ball mill-crusher configuration. The SAG mill was originally equipped with radial pulp lifters.

获取价格

Comminution Circuits for Gold Ore Processing - ScienceDirect

2016年1月1日 By combining with SAG discharge and screening on the SAG discharge screens, top-size control to the ball-mill circuit feed is maintained while still unloading the SAG circuit (Mosher et al, 2006). A variant of this method is to direct pebble-crushing circuit product to the ball-mill sump for secondary milling; while convenient, this has the

获取价格

Mill (grinding) - Wikipedia

Compared to ball mills HPGRs achieve a 30 to 50% lower specific energy consumption, although they are not as common as ball mills since they are a newer technology. A similar type of intermediate crusher is the edge runner, which consists of a circular pan with two or more heavy wheels known as mullers rotating within it; material to be crushed is shoved

获取价格