مسكن

>

modern blast furnace slag processing system

مسكن

>

modern blast furnace slag processing system

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

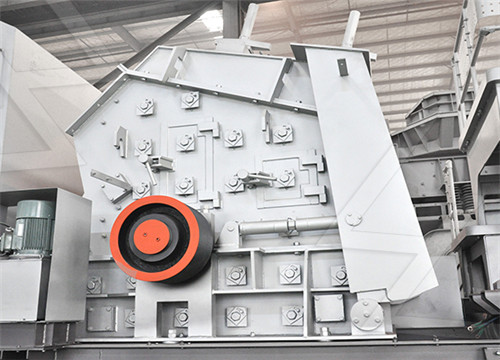

modern blast furnace slag processing system

Full article: Comprehensive utilisation of blast furnace slag

2023年7月21日 At present, although the comprehensive utilisation rate of domestic blast furnace slag is more than 80%. However, the blast furnace slag treatment is

获取价格

进一步探索

(PDF) The use of blast furnace slag - ResearchGate(PDF) Blast Furnace In Engineering Education - Blast Furnace Calculation PDF Blast Furnace Iron - ScribdWhat raw materials are used in a blast furnace? - AnswersBlast Furnace Slag Cement: Production, Properties and

Comprehensive utilisation of blast furnace slag - Taylor

industry, this paper will introduce the current status quo of comprehensive utilisation of blast furnace slag from the current blast furnace slag sensible heat recovery of molten steel.

获取价格

进一步探索

Blast Furnace Slag: Production, Types, Composition, Blast-furnace slag - ScienceDirect

Blast Furnace Ironmaking - Paul Wurth

The steel production transformation process in Europe: New slag

An Overview of Utilization of Blast Furnace and Steelmaking Slag

2019年1月1日 As one of the latest attempts to improve the recovery of waste heat in steelmaking process, Zhou et al. introduced a slag carbon arrestor process (SCAP) that

获取价格

Glass structure of industrial ground granulated blast furnace slags ...

2021年9月7日 Ground granulated blast furnace slag (GGBS) is a glassy by-product of hot metal production and has been used in blended cements for over 140 years [1,2,3,4].

获取价格

High-Temperature Physicochemical Properties of High Alumina

2022年8月19日 Slag is a complex oxides mixing system, and the influence of each component on its properties is not monotonous and linear. The use of high alumina iron

获取价格

Blast-furnace slag - ScienceDirect

2018年1月1日 Three significant types of BFS that are granulated, air-cooled, and expanded slags can be produced depending on the cooling and solidifying methods of molten slag.

获取价格

Mock-up performance evaluation study for crack

2 之 In this study, the drying shrinkage and crack reduction characteristics of blast furnace slag concrete mixed with expansive and swelling admixtures were investigated. Basic performance experiments ...

获取价格

Life cycle assessment of a novel blast furnace slag utilization

2022年7月15日 A novel system was proposed to realize the high value-added utilization of blast furnace slag. In this study, a comprehensive analysis concerning energy

获取价格

Modern Blast Furnace Ironmaking - Google Books

Modern Blast Furnace Ironmaking – An Introduction (Fourth Edition, 2020) describes the principles of the blast furnace process. As a starting point, the blast furnace is seen as a simple iron ore melter, while gradually the physical, chemical and metallurgical background of the blast furnace process is clarified. The book focuses on the control of the process

获取价格

Glass structure of industrial ground granulated blast furnace slags ...

2021年9月7日 Ground granulated blast furnace slag (GGBS) is a glassy by-product of hot metal production and has been used in blended cements for over 140 years [1,2,3,4].GGBS-containing binders and concretes have a lower CO 2 footprint, show a decreased heat development and an increased physical and chemical resistance [1, 3, 5,6,7,8].At high

获取价格

Comprehensive utilisation of blast furnace slag - Taylor

At present, although the comprehensive utilis-ation rate of domestic blast furnace slag is more than 80%. However, the blast furnace slag treat-ment is dominated by the water quenching pro-cess, and a large amount of physical sensible heat is wasted in the process of water slag ushing. fl.

获取价格

含钛高炉渣高效利用的最新进展 - USTB

文章亮点. (1) 系统总结了含钛高炉渣高效利用的各类途径。. (2) 对含钛高炉渣高效利用途径的作用机理进行了深入讨论。. (3) 指出新兴的理论研究、可靠的热力学数据库和先进的表征手段将有助于含钛高炉渣高效利用的进一步研究。. 含钛高炉渣是含钛冶金渣中 ...

获取价格

Electric Arc Furnace Process - an overview - ScienceDirect

A modern large blast furnace has a hearth diameter of 14–15 m, and a height of 35 m with an internal volume of about 4500 m 3. One such large blast furnace can produce 10,000 tons of hot metal per day (THM/day). Figure 1.1.2

获取价格

Mineralogy of Metallurgical Slags SpringerLink

2023年3月16日 In modern ferrous metallurgy, there are two main routes for steel production: the primary route converts iron ore via blast furnaces (BF) into pig iron, and pig iron via the BOF process into steel.The secondary route converts scrap via the electric arc furnace (EAF) into steel. The BF-BOF route contributes to 60% and the EAF route to

获取价格

Blast Furnace Ironmaking - Paul Wurth

Slag Granulation. Slag handling is an important aspect of modern blast furnace operation. Today, blast furnace slag is a value added product for the cement industry, using granulated slag sand as CO2-friendly substitute of clinker in cement production. Paul Wurth has developed the INBA® slag granulation process, incorporating our proprietary ...

获取价格

Processing and Reusing Technologies for Steelmaking Slag

As shown in Fig. 1, nearly 80% of blast furnace slag is granulat-ed slag produced by rapidly cooling hot molten slag (initially at a temperature of about 1,500°C) with a jet of high-pressure water. ... Steelmaking Slag Processing Technology The iron/steel slag processing flow is schematically shown in Fig. 2. Steelmaking slag is subjected to ...

获取价格

Modern Blast Furnace Ironmaking Technology Potentials

Advances in the blast furnace to reduce the coke consumption [18]. Parallel with the development of the top charging system, the hot stoves system at the lower part of the shaft has undergone ...

获取价格

Identification of the Elemental Composition of Granulated Blast Furnace ...

2022年10月22日 Blast furnace slag is a key large-tonnage waste product of metallurgical production, which is considered to be a promising alternative material in construction. In order to determine the scope of potential use of slag as a marketable product, it is necessary to study its structure and composition, which is determined by means of

获取价格

CHAPTER 1: Introduction: Metallurgical Slags - Royal Society of

2021年8月4日 Blast furnace slag may be recycled into the steel plant as a secondary source of Fe and as a pre-melted flux. 16 Furthermore, BOF slag can be recycled into the sinter and blast furnace process to recover Fe, and possible Mn, as well as being a source of fluxing compounds. 16 Additionally, Cu slag may contain a weight percent or more of

获取价格

Blast furnace - SMS group GmbH

A modern Bell Less Top ® (BLT) is a process-driven technological tool for controlling the blast furnace ‘from the top’, which is complemented by process know-how and mathematical modelling. With more than 800 systems delivered to customers worldwide, original and licensed BLT® technology is being used to produce about 60 % of all blast

获取价格

Metals Free Full-Text Experimental Study on Desulfurization and ...

2023年2月16日 The increased utilization of pellets in blast furnaces is one of the directions for low-carbon ironmaking. As a result, the low slag rate may affect the desulfurization of the hot metal and the removal of alkali in the blast furnace. Effective desulfurization and the removal of alkali in the low slag ironmaking process have become the focus of the steel

获取价格

Review and Analysis of Metallurgical Processes in Blast Furnace

2022年1月7日 A schematic of the taphole-trough system, used for removal of hot-metal and slag from an iron blast furnace is shown in Fig. 2a. Parallelly, for the sake of clarity of discussion and subsequent presentation, an equivalent depiction, deduced on the basis of water modelling [], is presented as Fig. 2b.This latter figure, as one would note here,

获取价格

CHAPTER 1: Introduction: Metallurgical Slags - Royal Society of

2021年8月4日 Blast furnace slag may be recycled into the steel plant as a secondary source of Fe and as a pre-melted flux. 16 Furthermore, BOF slag can be recycled into the sinter and blast furnace process to recover Fe, and possible Mn, as well as being a source of fluxing compounds. 16 Additionally, Cu slag may contain a weight percent or more of

获取价格

Blast furnace - SMS group GmbH

A modern Bell Less Top ® (BLT) is a process-driven technological tool for controlling the blast furnace ‘from the top’, which is complemented by process know-how and mathematical modelling. With more than 800

获取价格

Metals Free Full-Text Experimental Study on

2023年2月16日 The increased utilization of pellets in blast furnaces is one of the directions for low-carbon ironmaking. As a result, the low slag rate may affect the desulfurization of the hot metal and the removal of alkali in

获取价格

Review and Analysis of Metallurgical Processes in Blast Furnace

2022年1月7日 A schematic of the taphole-trough system, used for removal of hot-metal and slag from an iron blast furnace is shown in Fig. 2a. Parallelly, for the sake of clarity of discussion and subsequent presentation, an equivalent depiction, deduced on the basis of water modelling [], is presented as Fig. 2b.This latter figure, as one would note here,

获取价格

Automated Expert Systems in Blast-Furnace Process Control

2020年5月19日 Expert systems that recognize the state of a blast furnace, ensure its operational stability, and reduce the production costs are considered. An expert system based on a production model of knowledge representation is proposed. The knowledge is extracted from field data, blast-furnace operating experience, and iron production

获取价格

High-Temperature Physicochemical Properties of High Alumina Slag

2022年8月19日 Modern blast furnace ironmaking technology has a history of more than 100 years, and the impact of the high-temperature physicochemical properties of blast furnace slag on the process has been well-known by the metallurgists. Slag is a complex oxides mixing system, and the influence of each component on its properties is not

获取价格

LECTURE NOTES ON IRON MAKING SUBJECT CODE: PCMT

19 Blast furnace slag: composition and its control, Metal-slag reactions 20 Process Control: Factors affecting fuel consumption and productivity 21 Recent developments in Blast furnace operations like, Bell-less top charging system , High top pressure, Humidified ... A modern blast furnace plant mainly consists of:-

获取价格

Phase Equilibrium Studies in the CaO–SiO2–Al2O3–MgO System

2023年2月23日 With the raw materials for ironmaking are becoming increasingly complex, more accurate control of blast furnace operation is essential to reduce the energy cost and CO 2 emission. CaO–SiO 2 –Al 2 O 3 –MgO is a basic system of ironmaking slag in which CaO and MgO are mainly come from the flux, SiO 2 and Al 2 O 3 are mainly from the raw

获取价格

Automated Expert Systems in Blast-Furnace Process Control

2020年5月19日 A UTOMATED EXPERT SYSTEMS IN BLAST-FURNACE PROCESS CONTROL 7. sources); 8 V. B. TROFIMOV. Logical structure of expert system rules with respect to the feature “Total and partial gas pressure di ...

获取价格

Blast Furnace Ironmaking - an overview ScienceDirect Topics

2019年12月24日 The ironmaking blast furnace (BF) is a very energy-intensive metallurgical process and the prime route for steel production, from which about 70% of the world’s steel consumption is produced ( Geerdes et al., 2015 ). The BF system receives coke and ore solid raw material along with hot blast air and continuously produces hot

获取价格

Treatments and Recycling of Metallurgical Slags IntechOpen

In modern steel plants, the emphasis is placed simultaneously on quantity and quality. ... obtained through FactSage 7.2 in this study presents a valuable contribution to the understanding of the complex systems associated with slags at process conditions . ... thereby reducing energy consumption. Blast furnace slag is obtained at 1300–1400 ...

获取价格

A Review of Granulation Process for Blast Furnace Slag

Blast furnace slag is a by-product of blast furnace (BF) ironmaking produce. Every pig iron production is accompany by 0.3 ~ 0.6 tons of blast furnace slag produced with the temperature of 1350 ć ~1450 ć (1600~1 800 MJ sensible heat, equivalent to 55~61kg standard coal combustion after the heat generated). On this basis, the BF slag is up to ...

获取价格

Phase Equilibrium Studies of the CaO-MgO-Al2O3-SiO2 System

2023年4月19日 More and larger blast furnaces have been constructed for ironmaking across the world in recent years due to the advantages of high productivity, high energy efficiency and low cost. Slag plays important role in a blast furnace to produce high-quality hot metal and maintain smooth operations. Liquidus temperatures are the essential

获取价格

Pig Iron Production - Blast Furnace Route - Metallics

Blast furnace economics are such that larger units have lower unit production costs, hence there has been a trend to bigger and bigger furnaces. Modern blast furnaces produce more than 10,000 tonnes per day. For general information about merchant pig iron, please visit the pig iron page. Modern blast furnaces produce more than 10,000 tonnes per ...

获取价格