مسكن

>

crushing plant plant design layout

مسكن

>

crushing plant plant design layout

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

crushing plant plant design layout

My Plant Planner - Metso

A free-to-use drag and drop configurator that helps you design more productive and efficient plants through real-time insights. Launch My Plant Planner. Design and simulate a new crushing and screening plant in 3D

获取价格

The Ultimate Guide to Stone Crusher Plant Design

2023年2月28日 In this article, we will provide a comprehensive guide to stone crusher plant design, covering various aspects such as site selection, equipment selection, environmental management, safety,

获取价格

Crushing Plant Design and Layout - Yeco Machinery

Crushing Screening Plant Design Factors - 911

2016年4月14日 Crushing Plant Design and Layout ConsiderationsCrushing Circuit “A’’ shows a small simple layout for use in mills up to 100 tons. In order to keep the flowsheet simple, and because

获取价格

How to Design a Stone Crusher Plant Layout - LinkedIn

2023年5月11日 Designing a layout. A stone crusher plant designer follows three steps to create the layout: • Process design. • Equipment selection. • Layout. The principal design parameters driving the ...

获取价格

Mineral Processing Plant Design - University of Technology,

Crushing Plant Design and Layout Considerations Introduction In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimum. The fundamental goal for the design of a crushing plant is ...

获取价格

Crushing Plant Design and Layout Considerations - 911

The life of the mine is a key element in the design of any crushing plant. Short-term mine lives (three to eight years) require a very careful approach to design, layout and construction. Since the crushing plant’s structure and enclosure can represent the largest single cost element in a primary crushing plant, it is imperative to optimize ...

获取价格

Crushing and Screening Handbook - AusIMM

Whether you need a single crusher, a multi-stage process or a complete plant, we assist you with the right design for the most cost-eff ective crushing process. We are the world’s leading supplier of both unit machines and complete aggregates processing systems. Comprehensive process solutions Your system may involve a whole series of proc-

获取价格

The Ultimate Guide to Stone Crusher Plant Design - AGICO

2023年2月28日 Stone crusher plant design is a crucial factor in the efficient operation of the crushing process. The primary goal of plant design is to achieve the desired product size and capacity while balancing capital and operational costs. A well-designed plant will help minimize production downtime and reduce operating costs while maximizing

获取价格

Factors affecting the performance of crushing plant operations

2014年1月1日 Crushing Plant Design and Layout Considerations. ... the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping ...

获取价格

CRUSHING PLANT PROCESS OPTIMISATION

CRUSHING PLANT PROCESS DESIGN The crushing and screening process are normally divided into different stages. Each stage has the purpose of size reduction and often also classifi cation. The confi guration of a crushing stage varies depending on where in the process it is located and what task it is aimed to perform. One can also

获取价格

Setting up of crushing plant: design and layout considerations

2014年8月21日 There are three main steps in designing a good crushing plant: process design, equipment selection, and layout. The first two are dictated by production requirements and design parameters, but the layout can reflect the input, preferences and operational experience of a number of parties. These can include the owner’s engineering

获取价格

Layout of a four-stage crushing plant for ballast production.

Download scientific diagram Layout of a four-stage crushing plant for ballast production. from publication: Cone Crusher Performance PhD Thesis Cone crushers are used by both the aggregate ...

获取价格

Design of a crushing system that improves the crushing

The number of crushing stages necessary to reduce ore to the proper size varies with the type of ore. Hard ores like gold, iron, and molybdenum ores, may require as much as a tertiary crushing. To design a good crushing plant one has to follow these three steps: crusher selection, crusher layout and process design. 2.4 Crushers

获取价格

(PDF) Field monitoring and performance evaluation of crushing plant ...

Crushing plants are of great interest in reducing a particle size of rocks and ores as milling operations need to consider sustainable development. ... 2009. Improving yield and shape in a crushing plant, Minerals Engineering, Vol. 22, 618–624. BOYD K., 2003. Crushing plant design and layout considerations, Mineral Processing Plant Design ...

获取价格

Full Scale Systematic Optimization Steps for a Heap Leach

The design specifications were met (Table 1). The plant achieved 100% of -6 mm crushing product with the target size of 80% of -4.55 mm at a capacity of 200 (±10%) Mg/h. The product size for the best recovery, 3.35 mm, was measured between 63% and 68%. Secondary crushers achieved reduction ratio of 2–2.5 in average.

获取价格

Designing a Crushing Screening Plant – Part I. Primary Jaw Crushing

2020年10月27日 Jaw crusher stage with a screen in the grizzly by-pass to extract a 0-90 mm product. Figure 5. Jaw crusher stage with a screen that process all material and allows for production of 0-30 mm, 0-60 mm or 0‑90 mm. Figure 6. The rock size varies in the muck pile, as seen in the picture the number of large rocks is far greater on the right side.

获取价格

Design of a crushing system that improves the crushing

The number of crushing stages necessary to reduce ore to the proper size varies with the type of ore. Hard ores like gold, iron, and molybdenum ores, may require as much as a tertiary crushing. To design a good crushing plant one has to follow these three steps: crusher selection, crusher layout and process design. 2.4 Crushers

获取价格

(PDF) Field monitoring and performance evaluation

Crushing plants are of great interest in reducing a particle size of rocks and ores as milling operations need to consider sustainable development. ... 2009. Improving yield and shape in a crushing plant, Minerals

获取价格

Full Scale Systematic Optimization Steps for a Heap Leach

The design specifications were met (Table 1). The plant achieved 100% of -6 mm crushing product with the target size of 80% of -4.55 mm at a capacity of 200 (±10%) Mg/h. The product size for the best recovery, 3.35 mm, was measured between 63% and 68%. Secondary crushers achieved reduction ratio of 2–2.5 in average.

获取价格

Designing a Crushing Screening Plant – Part I. Primary Jaw Crushing

2020年10月27日 Jaw crusher stage with a screen in the grizzly by-pass to extract a 0-90 mm product. Figure 5. Jaw crusher stage with a screen that process all material and allows for production of 0-30 mm, 0-60 mm or 0‑90 mm. Figure 6. The rock size varies in the muck pile, as seen in the picture the number of large rocks is far greater on the right side.

获取价格

Design and Simulation Plant Layout Using Systematic Layout

2017年12月1日 The problem faced by this company is inappropriate layout causes cross traffic on the production floor. The re-layout procedure consist of these three steps: analysing the existing layout, designing plant layout based on SLP and evaluation and selection of alternative layout using Simulation Pro model version 6.

获取价格

MODELLING, SIMULATION AND OPTIMISATION OF A

design of a control model utilising two crusher variables and a self-tuning control algorithm. In this research work, a process model describing the dynamic operation of an Osborn 57S gyrasphere cone crusher is investigated. Modelling of the Mowana crushing circuit is carried out by combining the steady-state

获取价格

The Ultimate Guide to Designing an Efficient Aggregate Crushing Plant

2023年2月23日 This comprehensive guide provides valuable insights into the design and construction of an efficient aggregate crushing plant. From selecting the right equipment to optimizing the layout and process flow, this guide covers all aspects of designing a crushing plant that maximizes efficiency, productivity, and profitability.

获取价格

Five steps to implementing a new aggregate production line

2019年10月29日 An aggregate crushing plant may need to alter its product mix for a variety of reasons. Perhaps they are looking to sell to a new, more lucrative market, or their main client requests a different product. ... New design for the aggregate plant . The new design is based on the audit results – although w e ’re creat ing an entirely new layout ...

获取价格

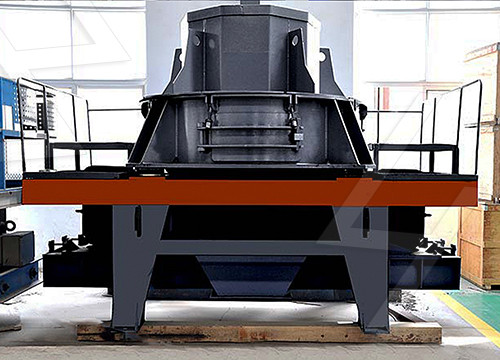

Crushing Plant Design and Layout - Yeco Machinery

A well-designed plant layout balances the capital versus operating cost over mine life. Buildings, infrastructure, and major equipment items, represent the major cost elements of a crushing plant. Yeco Machinery’s engineers will prepare a layout that suits the design criteria, flowsheet and selected equipment in the most economical possible ...

获取价格

crushing plant layout 3D CAD Model Library GrabCAD

2019年12月10日 The Computer-Aided Design ("CAD") files and all associated content posted to this website are created, uploaded, managed and owned by third party users. ... crushing plant layout crushing plant layout / Loading ... YTEAT-500X4000 BANT.SLDPRT. sldprt. December 10th, 2019 YTEAT-500X5000 BANT.SLDPRT. sldprt.

获取价格

(PDF) Crushing and Screening Handbook - Academia

Since the crushing plants operate under harsh conditions and involve very abrasive material, multiple factors can influence their performance. This paper assesses a number of factors affecting the performance of the crushing plant by addressing the critical design parameters and consideration of ore characteristics, operability and maintainability.

获取价格

Abdulraman S.O and Olaleye B - IJSER

A typical crushing plant product size distribution is shown in Table 1. However, with a thorough market survey of the product sizes in high demand in the locality where the quarry is proposed, the design can be tailored to satisfy the business objective. Unfortunately, this supply and demand gap analysis is not usually considered in the design ...

获取价格

Enhanced Plant Design for Aggregate Processing Agg-Net

2012年10月15日 Armed with such data, it is then feasible to proceed with the process of flow concept design, and the following are general points to be borne in mind for building an effective crushing and screening plant. Evaluation and calculation. The intention is to evaluate the content of the plant from in-feed to the plant through the various process

获取价格

BASIC CEMENT PLANT LAYOUT – Process Cement Forum - The

2020年2月3日 Crusher are mainly of two types viz. Jaw crusher and Hammer crusher. Jaw crusher is basically a simple mechanism having two plates one fixed and another moving. This is also called primary crusher. Hammer crusher has got metallic hammer mounted on the axes and the sizing achieved by the impact of the hammer. 13 Coal Mill

获取价格