مسكن

>

cement raw mill departments

مسكن

>

cement raw mill departments

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

cement raw mill departments

Raw Mill, Cement Raw Mill, Raw Mill In Cement Plant Cement

The start-stop of the raw mill has a great influence on the concentration of SO2in the waste gas of kiln tail. Raw mill is also known as cement raw mill, AGICO CEMENT supplies

获取价格

Raw Mill – Raw Mill In Cement Plant AGICO Cement Raw Mill

Cement ball mill and cement vertical mill are two raw mills commonly used in cement plants. As the main cement equipment in the cement production line, the two cement

获取价格

Cement - Extraction, Processing, Manufacturing Britannica

Cement - Extraction, Processing, Manufacturing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as

获取价格

Effects of occupational dust exposure on the health

2013年7月1日 Among exposed maximum of 36% were employed in Crushing department, 25% each in Packing and cement/raw mill. Systolic and Diastolic blood pressure was found to be higher among the exposed, which is ...

获取价格

Commissioning Guide Lines PDF Mill (Grinding)

Raw Mill Department. Before starting the raw mill following departments must have been tested and found fully able to operate from the PLC system in the CCR.. Feed to the Raw Mill. Raw Mill. Raw Mill Fan. Transport on

获取价格

List of Top Largest Cement Manufacturing Companies

2022年5月23日 The discharged raw mix is loaded onto a conveyor belt and processed through a bulk material analyzer (70%, clays 30%). The mixture is poured into raw mix storage, a circular storage container.

获取价格

Energy-Efficient Technologies in Cement Grinding IntechOpen

2016年10月5日 The moisture of the mill feed (cement raw material) can amount to 15–18 %. The fineness of the mill product can be adjusted in the range between 94 and 70 % passing 170 mesh. Capacities up to 400 t/h of cement raw mix are recorded . 2.3.1.1. ... Mining Engineering Department. University of Hacettepe; Ankara, Turkey: 2006.

获取价格

IMAQCS: Design and implementation of an intelligent

2013年4月1日 In this study, an agent-based model for controlling quality of process is proposed. We generate 42 rules for the stock pile, raw mill, raw material silo and clinker cooler departments. These rules are produced according to DAG (Directed Acyclic Graph). In these departments, the product has not yet formed in cement.

获取价格

(PDF) Mining Activities, Cement Production Process and

2022年7月4日 Figure 2.8: Showing the raw mill at stationary, Shayona cement factory. The raw mill has capac ity of 50 tons per hour and takes 300KW of electricity. The mill’s main

获取价格

Rawmill - Wikipedia

A medium-sized dry process roller mill. A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement mill.The raw milling stage of the process effectively defines the chemistry (and therefore

获取价格

Cemex’s most energy-efficient plant in the world and ... - Global Cement

2015年1月15日 It also has a 110t/hr raw mill and two cement mills, with 10t/hr and 40t/hr of cement production capacities. The Sv Kajo site has four cement silos, each of which can store 3000t of cement. When the site is operational, cement is dispatched in bulk by truck at a maximum rate of 1200t/day and 3000t/day of bulk clinker can be dispatched by truck.

获取价格

Evaluation of optimization techniques for predicting exergy

cement raw mill is the primary piece of equipment used in the modern cement industry for the raw meal production process. As a result, it is critical to investigate the exergy efficiency in a cement raw mill in order to satisfy the need for the design and optimization of the cement plant manufacturing process.

获取价格

Ventilation Prediction for an Industrial Cement Raw Ball Mill by

2021年6月10日 1. Introduction. In the cement industry, grinding is one of the most consuming energy stages in the production units. Around 65% of the total used electrical energy in a cement plant has to be utilized to grind raw materials, coal, and clinker [1,2].Through the process, many variables can affect the efficiency and productivity of this

获取价格

(PDF) CEMENT PRODUCTION PROCESS REPORT - A. SINOYA 1

2022年4月7日 Figure 2.8: Showing the raw mill at stationary, Shayona cement factory. The raw mill has c apacity of 50 tons per hour a nd takes 300KW of electricity. The mill ’s mai n

获取价格

Cement Production Process - AGICO

2020年8月25日 There are three steps of the high-temperature system: Drying or preheating, calcining, and sintering. The calcining is the core part of the clinker production; the raw meal is weighed and sent into preheater and cement kiln to process clinker. Grate cooler helps to cooler clinker, the cooled clinker is sent to the cement silo for storage.

获取价格

Cement Manufacturing Process - INFINITY FOR CEMENT EQUIPMENT

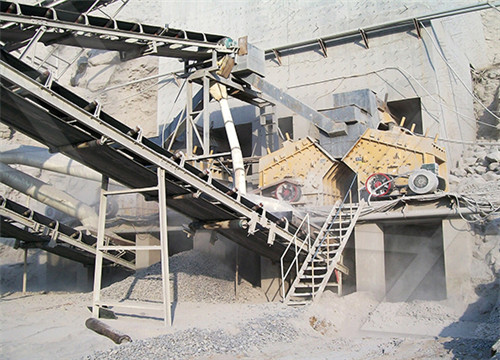

The raw materials are loaded at the blasting face into trucks for transportation to the crushing department. Clays and sand; Provide ingredients such as SiO 2, Al 2 O 3, Fe 2 O 3, and alkalis that take part in the formation ... Raw mill, Coal Mill and Cement mill drying; Heating and power generation; Speed of Clinker Cooling. cooling ...

获取价格

Engr Khalid Hussain - Assistant Manager - Thatta Cement

Troubleshoot mechanical faults arising during Raw mill Crusher Area operation. Operating and install all types of mechanical equipment, machines, gear boxes and components used in raw mill Crusher area. Coordination with relative departments in order to resolve. Mechanical problems arising during preventive maintenance.

获取价格