مسكن

>

mou for testing crushing machinery used for mineral crushing

مسكن

>

mou for testing crushing machinery used for mineral crushing

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

mou for testing crushing machinery used for mineral crushing

sbm mou for testing crushing machinery used for mineral ... - GitLab

About GitLab GitLab: the DevOps platform Explore GitLab Install GitLab Pricing Talk to an expert /

获取价格

m/sbm mou for testing crushing machinery used for minera.md at

Contribute to legaojm/m development by creating an account on GitHub.

获取价格

New testing methodology for the quantification of rock ... - Springer

2018年10月30日 Investigations on rock crushability have become an important issue in mining operations and the manufacture of industrial crusher equipment. The main

获取价格

METALLURGICAL TESTING METHODS (RENISON, TASMANIA

intermediate scale pilot-plant testing. 2 SAMPLE PREPARATION, CRUSHING AND GRINDING 2.1 Introduction This section of the laboratory manual discusses aspects of

获取价格

A Process for Reducing Rocks and Concentrating Heavy

The equipment typically used in a rock-preparation labo-ratory includes a rock hammer, a splitter, a jaw crusher, and a horizontal disk grinder. These are all impact devices intended to systematically reduce the size of the whole rock sample. Crush Grind Sieve Wilfley Table Magnetic separation Heavy liquid Mineral concentrate Process Flow Chart

获取价格

(PDF) An experimental investigation on rock

2019年4月18日 Abstract and Figures. This study covers the investigation of rock crushability using laboratory-scale cone and jaw crushers for five types of hardrocks. For this purpose, physico-mechanical ...

获取价格

Crushing-Screening Flowsheet of Concentrator SpringerLink

2023年7月21日 The three-stage crushing-screening flowsheet of concentrator is suitable for processing ores with high mud content in underground mining and open-pit mining. It simplifies the equipment configuration of the crushing plant to a certain extent and reduces its capital investment cost. If the ore grinding operation is not strict on the particle ...

获取价格

Types of Crushers - 911 Metallurgist

2015年6月23日 Crushers may be divided into three general classes, with respect to the manner in which they do their work: Pressure Crushers: This category embraces the several types of gyratory crushers and jaw crushers, as well as the double crushing rolls, with either smooth or corrugated shells. Impact Crushers: This division is represented chiefly by the

获取价格

Types of Crushers: What You Need to Know - Machinery Partner

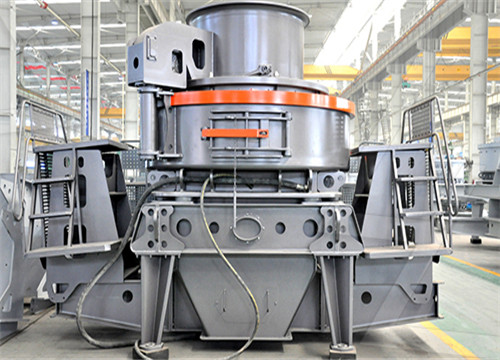

For example crushed material for road base and fill. The main kinds of crushing machines for secondary processing are discussed below. Cone crushers. Cone crushers are one of the main choices for secondary crushing. A cone crusher is a powerful machine that is used in large-scale industries for crushing various types of materials into smaller ...

获取价格

Bond Impact Crushing Work Index Testing Machine

The Pendulum Tester / Bond Impact Crushing Work Index Tester. Working principle Crushing by impact. 76 mm maximum feed size. Test repetition: At least 10, preferably 20 test runs. Adjustable crushing angle Repeatable crushing results Safe two-hand operating buttons The Bond Crushing Work Index (CWI) describes the competency of the ore at

获取价格

Design of a crushing system that improves the crushing

has to follow these three steps: crusher selection, crusher layout and process design. 2.4 Crushers . A crusher is a tool or machine that is used to reduce the size of a large solid particle to a smaller solid particle. The ore can have a size of up to 400mm. There are many types of crushers but the major ones are the jaw, gyratory and the cone ...

获取价格

Crushers, Pulverizers Mills - Gilson Co. - GlobalGilson

Crushers, Pulverizers Mills. Particle-size reduction, or comminution, is often required to prepare bulk material samples for testing. Crushing is often the initial step with materials such as mineral ores or aggregates using varying combinations of force, impact, and compression to initiate fracturing in the materials.

获取价格

Crushing 101 – Different types of crushers for distinctive needs

2020年12月17日 Jaw crushers can be divided into two basic types, single and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation, along with the toggle plate, causes a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top

获取价格

Laboratory Sample Pulverizers - 911 Metallurgist

2015年5月24日 The crusher unit is the 2 ¼” x 3 ½” (Type I) Forced Feed Laboratory Jaw Crusher, which is of the high capacity type with a one-piece cast alloy iron frame and reversible manganese steel jaw and cheek plates. This crusher-pulverizer unit is a compact, efficient, portable combination, ideal for use in any laboratory.

获取价格

Crushing in Mineral Processing - Eastman Rock Crusher

2020年4月20日 The products can be extracted immediately after the gyratory crusher as 0-32 mm or 0-63 mm fractions, if necessary; these materials are used when stability is needed for the given construction application. The tertiary stage produces fractions in sizes ranging from 0-2 mm to 16-32 mm. These products are used in asphalt and concrete.

获取价格

Portable crushers - Metso

Portable crushers, or portable crushing plants, are wheel-mounted crushing machines that are made to process rocks and other hard materials. They can operate independently or as part of a larger fleet. Many portable crusher models can be equipped with an integrated feeder and a screen into the same frame. Thanks to transportability, portable ...

获取价格

Understanding Comminution: Compression versus impact crushing

2020年9月16日 Compared with compression crushing, impact crushing will create more fines within the circuit, which will cause greater wear if processing abrasive material. This is why rocks with lower silica content are more suited to reduction by impact crushers. When compared with cone crushers, impact crushers often have a lower capital cost, but can ...

获取价格

Response to Comments, AP42 Section 11.19.2 Crushed Stone

MINERAL PROCESSING NOTICE ... crushing, and screening processing ... data or data from equipment vendors] is not available, use of emission factors may be necessary as a last resort.” The revised AP-42 Emission Factors

获取价格