مسكن

>

coal mill in power plant

مسكن

>

coal mill in power plant

منتج

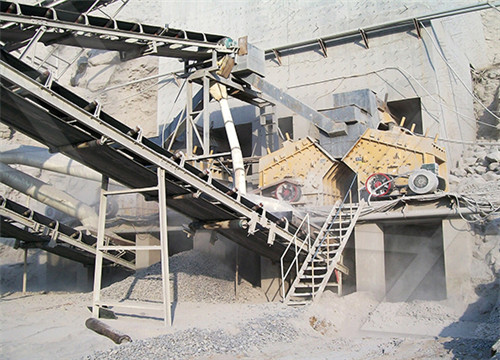

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

coal mill in power plant

Coal mill pulverizer in thermal power plants PPT - SlideShare

data-id="" >ResearchGate

An investigation of performance characteristics and

2020年8月12日 Abstract and Figures. This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coal-fired power plant. In a power plant, the coal mill is the critical ...

获取价格

Monitoring Model of Coal Mill in Power Plant Based on Big Data

Abstract: In order to monitor the wear condition of grinding roller of coal mill in power plant and improve the reliability of production equipment, it is necessary to establish a state

获取价格

Pulverizer - Wikipedia

A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for combustion in the

获取价格

Boiler Mill and Coal Pulverizer Performance GE Steam Power

YES. Our boiler mills and coal pulverizers span the globe and are built in a variety of sizes and capacities. We provide customized maintenance solutions, and offer a full spectrum of high-quality solutions for each—in addition to our thousands of standard boiler mill parts and boiler service solutions. This is the Power of Yes.

获取价格

How does a coal mill work? - LinkedIn

2022年12月30日 The coal mill is an important part of the coal-fired power plant because it is used to crush and grind the coal into a fine powder, which increases the efficiency of the coal-burning process.

获取价格

Pulverizer - Wikipedia

Pulverizer. A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for combustion in the steam-generating furnaces of coal power plants .

获取价格

Mill Creek Generating Station LGE and KU

The Mill Creek Generation Station is LGE’s largest coal-fired power plant, with a generating capacity of 1,465 megawatts. Mill Creek sits on 544 acres in southwest Jefferson County, Ky. The late 1960s and early 1970s saw an unprecedented increase in the construction of new industrial, commercial, and residential facilities in the Louisville ...

获取价格

classifications and working of mills in a power plant PPT

2020年6月29日 5. CLASSIFICATION OF MILLS LOW 10-20 rpm MEDIUM 40- 70 rpm HIGH 900- 1000rpm SPEED BALL TUBE MILL BOWL MILL, BALL RACE MILL HAMMER MILL TYPE ATTRITION CRUSHING IMPACT DOMINATING PRINCIPAL. 6. TYPES OF COAL PULVERIZER • Tube or ball mills: Low-speed machines that grind the coal with

获取价格

What are Coal feeders? Principle, components.

What are coal feeders? Coal Feeder is a device that regulates the amount of coal to be supplied into the Coal Mill. The amount of coal is regulated according to the needs in the boiler combustion chamber (furnace). The number regulation system in the coal feeder can be done in two ways based on the type, namely by weight fraction or coal volume ...

获取价格

Power Mills Mill Technology GE Steam Power

For nearly 100 years—ever since pulverized coal combustion was adapted for power generation—GE has been a leader in coal mill technology for the power industry. That leadership continues today with the world’s largest fleet of installed power milling equipment. Licenses for our milling technology can be found in all coal-powered regions ...

获取价格

Modeling of Coal Mill System Used for Fault Simulation - MDPI

2020年4月7日 Monitoring and diagnosis of coal mill systems are critical to the security operation of power plants. The traditional data-driven fault diagnosis methods often result in low fault recognition rate or even misjudgment due to the imbalance between fault data samples and normal data samples. In order to obtain massive fault sample data

获取价格

TPS Coal Mills and Fan Performance PPT - SlideShare

2019年5月8日 SCOPE • Various types of Coal mills can be found in the Power Industry. The type of Coal mill under discussion within this Presentation is a “Bowl Mill” (Bowl and Rollers), typically used by the power industry. 5/8/2019 Manohar Tatwawadi 2

获取价格

Analysis of the Coal Milling Operations to the Boiler Parameters

The coal milling plant consists of 7 vertical bowl mills. ... The mill design in the power plant is a vertical bowl. The mill rotated on his axis at minimum speed 35rpm by a motor-reducer train. The grinding rolls are supported by three oscillating journals. The rolls rotate freely crushing the

获取价格

Dominion agrees to study viability of Wise power plant that's not ...

2022年3月30日 With a coal plant that’s costing ratepayers millions but not producing much electricity, Dominion Energy has agreed to conduct an analysis of how it could make the Virginia City Hybrid Energy Center in Wise County economically viable in the future. “The company has acknowledged that the economics of the station are challenged at the

获取价格

An investigation of performance characteristics and energetic ...

2020年8月12日 In a coal-fired power plant, one of the main equipment is the coal mill, whose effectiveness influences mainly the whole power plant performance (Shah, Vuthaluru, and Vuthaluru 2009 ).

获取价格

Analysis of the Coal Milling Operations to the Boiler Parameters

2020年4月2日 Milling system in coal power plant purposely to process the raw coal to become as pulverise fuel before enter to the boiler furnace. ... Coal mill . motor . power (kW) 0 . 417.1 . 454.8 . 439.0 ...

获取价格

A Control Strategy of the Air Flow Rate of Coal-Fired Utility Boilers ...

2020年11月25日 2.2. Effectiveness of the New Air Flow Rate Control Strategy. The original operating parameters of the power plant as the load increases from 160 to 240 MW over 2 h are shown in. Figure 5. Transient processes of the primary parameters of the power plant. ) and the air/fuel ratio () for typical loads: (a) 270, (b) 280, (c) 290, and (d) 300 MW.

获取价格