مسكن

>

magnetite iron ore beneficiation technology

مسكن

>

magnetite iron ore beneficiation technology

منتج

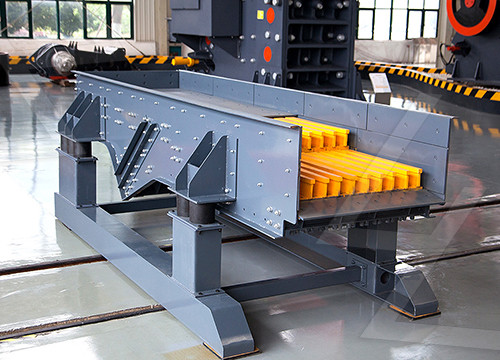

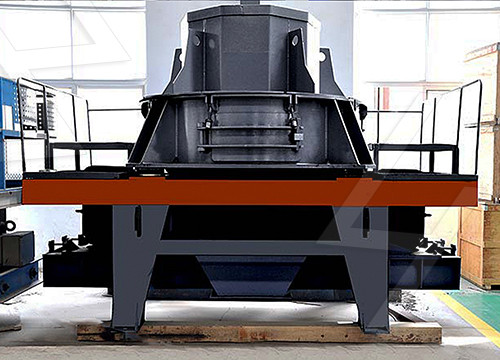

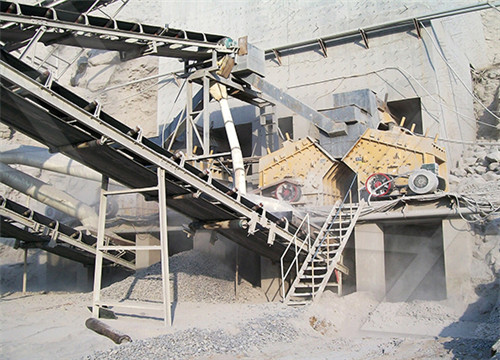

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

magnetite iron ore beneficiation technology

Iron ore quality a potential headwind to green steelmaking –

Steel Sector Decarbonisation Focused on Green HydrogenSeaborne Iron Ore Supply by Fe ContentBig Four Iron Ore Miners Largely Focused on Supplying Blast FurnacesOptions to Enable Global Dri Expansion Going ForwardThe availability of DR-grade iron ore is a potential challenge to the global expansion of DRI technology. Among options to address this issue is a significant switch in iron ore mining focus from hematite towards magnetite. Magnetite ores tend to have a much lower Fe content but are often suitable for significant beneficiation, in part because magn...

(PDF) Beneficiation of Complex Banded Iron Ores Using

2019年12月17日 The magnetite-rich (O1) and the goethite-rich (O2) ore have been subjected to MW assisted reduction-magnetic separation to obtain useful iron ore concentrates with more than 62-63% Fe....

获取价格

Economic and Socio-Environmental Benefits of Dry Beneficiation

Improved iron recovery from low-grade iron ore by efficient

2022年8月1日 Therefore, improvement of the beneficiation technology is a fundamental method to solve the aforementioned problems. With the development of the conventional beneficiation technology, some researchers have prioritized the separation of low-grade iron ores by gravity separation, magnetic separation, or flotation or a combination of

获取价格

Iron ore beneficiation process Prominer (Shanghai) Mining Technology

2021年5月25日 The following is a summary of the common iron ore beneficiation technology: 1.Magnetic separation of ore (1)single magnetite. Most of the iron minerals in single magnetite are magnetite. This type of ore has the longest history of beneficiation. Because of the simple composition of the ore, weak magnetic separation methods are

获取价格

Economic and Socio-Environmental Benefits of Dry

2020年10月26日 Iron (Fe) ores play a significant role in the global mining industry judging by the high tonnes of ore processed yearly and the associated energy, water, and tailings storage facility (TSF) requirements

获取价格

Iron ore beneficiation: an overview - ScienceDirect

2023年1月1日 2.4. Beneficiation methods. Beneficiation is a process where ore is reduced in size and valuable minerals are separated from the gangue minerals. Separation of valuable minerals from gangue minerals can be efficiently achieved by taking advantage of the differences in physical, surface, and magnetic properties.

获取价格

Iron ore - Wikipedia

Iron ores [1] are rocks and minerals from which metallic iron can be economically extracted. The ores are usually rich in iron oxides and vary in color from dark grey, bright yellow, or deep purple to rusty red. The iron is usually found in the form of magnetite ( Fe. 3O. 4, 72.4% Fe), hematite ( Fe. 2O.

获取价格

(PDF) Beneficiation of Complex Banded Iron Ores Using

2019年12月17日 The effective gravity and magnetic technology of thin impregnated complex iron ore benificiation has been established. The technology ensures high recovery of all mineral forms of iron in the ...

获取价格

BENEFICIATION OF IRON ORE - National Institute of

economy. India has huge reserves of quality iron ore which can fulfil the growing demand for domestic iron and steel industry as well as sustain large external trade. The most important iron ore types found in India are hematite and magnetite. Nearly 61% of hematite ore deposits are found in the eastern part of India and 82% of magnetite ore ...

获取价格

Iron ore quality a potential headwind to green steelmaking – Technology

2022年6月28日 As a result of long lead times for new magnetite project proposals and beneficiation challenges, more DRI may need to be made using lower-grade iron ore. This will necessitate melting the reduced iron before being charged into a basic oxygen furnace.This type of technology combination is being investigated by Rio Tinto in

获取价格

Iron Ore Geoscience Australia

2023年12月19日 The Brockman Iron Formation in this province is the most significant host for high-grade hematite iron ore deposits. Magnetite is an iron oxide mineral that is generally black and highly magnetic. The latter property aids in the beneficiation of magnetite ores. Magnetite contains 72.4% Fe by molecular weight, which is higher than

获取价格

Iron ore beneficiation: an overview - ResearchGate

2023年1月1日 The iron-making process requires high-quality raw materials, with Fe ≥ 64% and <2% alumina and silica each, to enhance blast furnace productivity at a given energy consumption rate. There is a ...

获取价格

Existing and New Processes for Beneficiation of Indian Iron

2020年2月8日 Magnetic carrier technology has been established in the commercial-scale for wastewater treatment but needs to be translated in iron ore beneficiation by incorporating natural or colloidal magnetite. Similarly, bio-beneficiation processes with gangue reducing bacteria have to be studied at a much larger scale before they see the

获取价格

Beneficiation of Clay-Rich High-LOI Low-Grade Iron Ore Fines ...

2022年6月4日 The unutilized iron ore fines (IOF, − 10 mm, 45% to < 60% Fe(T)) left at various mine sites during blasting and processing are rich in goethetic-hematite associated with high clay and considered a potential iron ore resource. The variation of loss on ignition (LOI) from mines to mines is based on the goethite and clay mineral content. The clay

获取价格

How To Beneficiation Various Types Of Iron Ore - LinkedIn

2022年5月28日 Siderite ore beneficiation technology. Because the theoretical iron grade of limonite is low, and often with calcium, magnesium, manganese is a homogeneous symbiosis, so the use of physical ...

获取价格

Recent Trends in the Technologies of the Direct Reduction

2023年4月5日 The blast furnace and direct reduction processes have been the major iron production routes for various iron ores (i.e. goethite, hematite, magnetite, maghemite, siderite, etc.) in the past few decades, but the challenges of maintaining the iron and steel-making processes are enormous. The challenges, such as cumbersome production

获取价格

Existing and New Processes for Beneficiation of Indian Iron

2020年2月8日 Magnetic carrier technology has been established in the commercial-scale for wastewater treatment but needs to be translated in iron ore beneficiation by incorporating natural or colloidal magnetite. Similarly, bio-beneficiation processes with gangue reducing bacteria have to be studied at a much larger scale before they see the

获取价格

Beneficiation of Clay-Rich High-LOI Low-Grade Iron Ore Fines ...

2022年6月4日 The unutilized iron ore fines (IOF, − 10 mm, 45% to < 60% Fe(T)) left at various mine sites during blasting and processing are rich in goethetic-hematite associated with high clay and considered a potential iron ore resource. The variation of loss on ignition (LOI) from mines to mines is based on the goethite and clay mineral content. The clay

获取价格

How To Beneficiation Various Types Of Iron Ore

2022年5月28日 Siderite ore beneficiation technology. Because the theoretical iron grade of limonite is low, and often with calcium, magnesium, manganese is a homogeneous symbiosis, so the use of physical ...

获取价格

Recent Trends in the Technologies of the Direct Reduction

2023年4月5日 The blast furnace and direct reduction processes have been the major iron production routes for various iron ores (i.e. goethite, hematite, magnetite, maghemite, siderite, etc.) in the past few decades, but the challenges of maintaining the iron and steel-making processes are enormous. The challenges, such as cumbersome production

获取价格

Magnetic separation studies for a low grade siliceous iron ore sample ...

2013年1月1日 The investigations carried out on the low grade iron ore sample reveal the following conclusions. (1) The sample on average contains 43.8% Fe, 16.8% SiO 2 and 5.61% Al 2 O 3. (2) The mineralogical studies indicate that the major iron minerals are magnetite, hematite and goethite. And the gangue minerals are silicates and calcites.

获取价格

Iron Ore ScienceDirect

Iron ore is regarded as the second most important commodity behind oil. As an essential input for the production of crude steel, iron ore feeds the world’s largest trillion-dollar-a-year metal market and is the backbone of global infrastructure. To meet the growing demand for steel products, world iron ore production has increased ...

获取价格

Magnetizing Reduction and Magnetic Separation Studies on

magnetic iron ore (magnetite) from a variety of less magnetic or nonmagnetic material [7]. Magnetizing reduction is one of the most effective unit operations in the treatment of low-grade iron ores specially those which are poorly responsive to conventional beneficiation techniques such as froth flotation, gravity separation

获取价格

Eco-efficient and cost-effective process design for magnetite iron ore ...

2015年2月24日 The majority of steel production is supported by iron ore sourced from high-grade hematite deposits, although a significant fraction comes from magnetite deposits. Compared to direct shipping hematite ores mined from the upper regolith, magnetite deposits require significant beneficiation, which typically involves grinding to

获取价格

(PDF) Mineral and Technological Features of Magnetite

2021年3月24日 Mineralogical studies have established that the main iron-bearing mineral is hematite, which contains 69.02 to 70.35% of iron distributed in the ore. Magnetite and hydrogoethite account for 16.71 ...

获取价格

Minerals Free Full-Text Recovery of Hematite from Banded

2022年8月29日 Monograph on Iron Ore; Indian Bureau of Mines: Nagpur, India, 1997. [Google Scholar] Raj, B. Development of a Process flow sheet for Beneficiation of Indian Banded Hematite Quartz (BHQ) Iron Ore. In Proceedings of the Iron Ore 2007 Conference Perth: AusIMM, Perth, Australia, 20–22 August 2007; pp. 375–380. [Google Scholar]

获取价格

Synthesis of magnetite powder from iron ore tailings

2010年7月26日 Iron ore tailing—a waste material of mineral beneficiation plants, is used as a source of iron for synthesizing magnetite powder. Iron ore tailings containing 15.98% Fe 2 O 3, 83.36% SiO 2 and 0.44% Al 2 O 3 have been subjected to HCl digestion on a hot plate to extract the entire amount of Fe 2 O 3 as FeCl 3.A portion of extracted FeCl 3

获取价格

Influence of Magnetite Grain Size on Magnetic Susceptibility of Iron

2023年7月5日 For additional beneficiation of rough magnetite concentrate, Vertimill vertical mills (Metso, ... The use of magnetic gravity separation in the iron ore concentrate production technology combined with fine screening allows removing high-quality concentrate from the process already at the initial beneficiation stages .

获取价格

Comminution and classification technologies of iron ore

2022年1月1日 Due to the depleting reserves of DSO ores and increasing development of low-grade hematite and magnetite deposits, the need for iron ore comminution and beneficiation is increasing. Even the DSO ores are requiring a higher level of processing as mining operations are extended below the water table where ores are wet and more

获取价格

A new approach for recovering iron from iron ore tailings using ...

2020年2月1日 Magnetization roasting followed by magnetic separation has been considered as the most effective technology for iron recovery from iron ore tailings [[9], ... Phase transformation during roasting process and magnetic beneficiation of oolitic-iron ores. Vacuum., 146 (2017), pp. 63-73, 10.1016/j.vacuum.2017.09.029. View PDF View

获取价格