مسكن

>

equipment used in iron ore process india

مسكن

>

equipment used in iron ore process india

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

equipment used in iron ore process india

Iron ore beneficiation: an overview - ScienceDirect

2023年1月1日 This chapter briefly discusses the current scenario of the following: iron ore resources in India, iron ore mining methodology, beneficiation techniques for various

获取价格

进一步探索

(PDF) An overview of the beneficiation of iron ores via Iron ore beneficiation: an overview - ResearchGate

India - Mining Mineral Processing Equipment

2019年10月13日 NMDC Limited (nmdc.co) is India’s largest iron ore producer and exporter, mining over 30 million tons per year from its three fully-mechanized mines.

获取价格

进一步探索

India - Mining Mineral Processing Equipment export.govMINING Equipment List Mining Tools Names + Underground

Iron ore beneficiation Commodities Mineral Technologies

Extending beyond traditional spiral plants our designs for fine iron ore beneficiation incorporate gravity and magnetic beneficiation equipment with capacities ranging from 5

获取价格

Iron processing Definition, History, Steps, Uses, Facts

2023年12月18日 iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned. Included in this article also is a discussion of the mining of iron and of its preparation for

获取价格

Existing and New Processes for Beneficiation of Indian Iron ores

2020年2月8日 The iron ore industries of India are expected to bring new technologies to cater to the need of the tremendous increase in demand for quality ores for steel making.

获取价格

Iron Ore Characterization Techniques in Mineral Processing

2023年4月27日 Consequently, this review highlights some of the primary characterization tests such as SEM (Scanning Electron Microscopy), XRD (X-ray Diffraction), and FTIR

获取价格

How the Iron Ore Market Works - Investopedia

2022年1月24日 In 2020, iron ore saw decreases in production, trade, and shipments due to the COVID-19 pandemic, leading to a global reduction in steel consumption and production. As a result, prices dropped to ...

获取价格

Iron ore pelletizing - Metso

Our iron ore pelletizing systems combine the best features of both technologies to provide the most modern plant and to produce pellets at the lowest cost and highest quality. Pellet plants sized from 1.2MTPA to

获取价格

Iron Ore, Types, Uses, Distribution in India World Map

2023年6月28日 Iron Ore Types. They are classified according to the percentage of metallic iron in them: Magnetite: It is the most valuable type of iron ore. It is made up of more than 70% metallic iron. It is black and

获取价格

Iron Ore Mining – The process of iron ore mining %y - AtlamGroup

The world’s reserves of iron ore are estimated to be around 170 billion tonnes, with the majority of these reserves located in Australia, Brazil, China, India, and Russia. These four countries account for about 85% of the world’s total iron ore reserves. How is Iron Ore Used? Iron ore is used in a variety of different ways.

获取价格

Process flow diagram of pelletization unit - ResearchGate

Download scientific diagram Process flow diagram of pelletization unit from publication: Techno-economic Evaluation of Iron Ore Pellet Manufacturing Processes in India and Justification for new ...

获取价格

Novel Technology for Comprehensive Utilization of Low-Grade Iron Ore

2022年4月18日 In this study, a novel technology for the comprehensive utilization of low-grade iron ore is presented. For the iron ore with a Fe content of 24.91%, a pilot-scale study of pre-concentration, suspension magnetization roasting, grinding, and low-intensity magnetic separation was conducted, and an iron concentrate with a grade of 62.21% and

获取价格

Metallurgical Testing for Iron Ore - SGS

The commonly used beneficiation techniques follow: • Gravity Separation recycled resources and their subsequent Spirals are the most practical equipment to use for gravity separation of iron ores because of the high throughputs needed. SGS has a variety of spiral test rigs, including the spiral designs typically used in iron ore plants.

获取价格

SAFETY GUIDELINES FOR IRON STEEL SECTOR MINISTRY

2.1 Process of receiving raw material The location of a pelletizing plant affects the method of receiving raw materials such as iron ore, additives and binders. 2.2.1 Pre-treatment process of Iron Ore Fines In the pre-treatment process, iron ore fines are ground into finer size, suitable for green ball formation.

获取价格

Life cycle assessment of iron ore mining and processing

2015年1月1日 Abstract. Mining of iron ore is a highly capital- and energy-intensive process. Life cycle assessment (LCA) of the mining and mineral processing of iron ore in Australia was carried out in this chapter using SimaPro LCA software as a case study. The environmental impacts considered in the study were embodied energy and greenhouse

获取价格

Iron ore pellets as a solution to steel—making raw ... - Springer

2013年10月22日 The capacity increased from 20.70 in 2010 to 37.4 Mt/year. This has been necessitated by a drop in iron ore production through bans on production as a result of illegal mining detected in iron ore-producing states like Karnataka and Goa and imposed caps on production on well-known iron ore-producing belts of Orissa.

获取价格

Minerals Free Full-Text Recovering Iron from Iron Ore Tailings

2019年4月15日 Iron ore tailings (IOTs) are a form of solid waste produced during the beneficiation process of iron ore concentrate. In this paper, iron recovery from IOTs was studied at different points during a process involving pre-concentration followed by direct reduction and magnetic separation. Then, slag-tailing concrete composite admixtures

获取价格

Understanding How The Indian Steel Industry Works Part 1

Currently, Indian steel industry has a steel capacity of 122 million tonnes (2015-16) and the world is producing 1630 million tonnes of steel. India has an aspiration to take this capacity to 300 million tonnes by 2030. Today steel industry contributes approximately 2% to our country’s GDP and employs 5 lakh people directly and about 20 lakh ...

获取价格

Iron Ore Pelletizing Process: An Overview IntechOpen

2018年7月11日 The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries. However, the content of iron in ore deposits has deteriorated and low-grade iron ore has been processed. The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking.

获取价格

Iron ore beneficiation Commodities Mineral Technologies

The world’s largest producers rely on Mineral Technologies for iron ore processing solutions. From Canada’s Labrador Trough region, across India, Brazil and Africa, to Australia’s iron rich Pilbara, our teams deliver unrivalled expertise in fine iron ore beneficiation. Mineral Technologies can assist you to deliver a comprehensive range ...

获取价格

Minerals Free Full-Text Recovering Iron from Iron Ore Tailings

2019年4月15日 Iron ore tailings (IOTs) are a form of solid waste produced during the beneficiation process of iron ore concentrate. In this paper, iron recovery from IOTs was studied at different points during a process involving pre-concentration followed by direct reduction and magnetic separation. Then, slag-tailing concrete composite admixtures

获取价格

Understanding How The Indian Steel Industry Works Part 1

Currently, Indian steel industry has a steel capacity of 122 million tonnes (2015-16) and the world is producing 1630 million tonnes of steel. India has an aspiration to take this capacity to 300 million tonnes by 2030. Today steel industry contributes approximately 2% to our country’s GDP and employs 5 lakh people directly and about 20 lakh ...

获取价格

Iron Ore Pelletizing Process: An Overview IntechOpen

2018年7月11日 The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries. However, the content of iron in ore deposits has deteriorated and low

获取价格

Iron ore beneficiation Commodities Mineral Technologies

The world’s largest producers rely on Mineral Technologies for iron ore processing solutions. From Canada’s Labrador Trough region, across India, Brazil and Africa, to Australia’s iron rich Pilbara, our teams deliver unrivalled expertise in fine iron ore beneficiation. Mineral Technologies can assist you to deliver a comprehensive range ...

获取价格

Steelmaking - Wikipedia

Steelmaking. Steelmaking is the process of producing steel from iron ore and/or scrap. In steelmaking, impurities such as nitrogen, silicon, phosphorus, sulfur and excess carbon (the most important impurity) are removed from the sourced iron, and alloying elements such as manganese, nickel, chromium, carbon and vanadium are added to produce ...

获取价格

Hazard Identification, Risk Assessment, and Control Measures

General. India has the fourth largest iron ore reserves in the world after Russia, Brazil, and Australia.[] As per the survey conducted by the Indian Bureau of Mines (IBM) in April 2000, India had 9919 million tonnes of recoverable reserves of haematite and 3546 million tonnes of magnetite.[]As good quality iron ore deposits are depleting very fast, beneficiation

获取价格

Iron Ore Agglomeration Technologies IntechOpen

2017年12月20日 Until the 1950s of the last century, the oxidized iron ores that were loaded into the blast furnace had granulometries within 10 and 120 mm. However, the depletion of high-grade iron ore sources has made necessary the utilization of concentration processes with the purpose of enriching the iron ore. Because of these processes, a fine

获取价格

PROCESS BRIEF - Ministry of Steel

GOVT. OF INDIA SINTER PLANT Doc. No: RG / 05 Rev no.: 00 Effective Date: -- 1. OBJECTIVE Sintering is an agglomeration process of fine mineral particles into a porous mass by incipient fusion caused by heat produced by combustion within the mass itself. Iron ore fines, coke breeze, limestone and dolomite along with

获取价格

Guide for iron ore dressing - LinkedIn

2019年4月9日 Generally, iron ore with a grade of less than 50% needs to go through a dressing process before it can be sent to smelting for utilization. After the mined ore goes through the processes of ...

获取价格

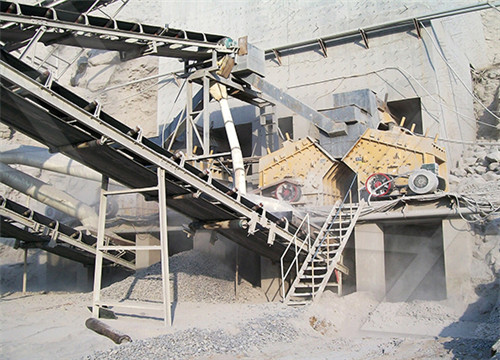

HOW DOES MINING EQUIPMENT WORK IN IRON ORE MINING?

2017年6月28日 Hematite and limonite, magnetite and goethite, the mining operation is extracting the rock and crushing it until the rocky deposits are evenly sized. Remember, the deposits are somewhat soft, even crumbly, but there’s raw iron trapped inside the ore. Given time, the ore will age the mining equipment, deform the system parts, and

获取价格

OPTIMIZATION OF IRON ORE PELLETS PRODUCTION IN

1.1 Iron Ore Pellets Pellets are little iron ore balls used in the steelmaking process. They're made employing technology that makes use of powder that's created during the ore extraction procedure. Pellets are used to make steel, which is utilised in the construction of bridges, automobiles, planes, bicycles, household goods, and much more.

获取价格

Life cycle assessment of iron ore mining and processing

2015年12月31日 Mining of iron ore is a highly capital and energy-intensive process. Life cycle assessment of the mining and mineral processing of iron ore in Australia was carried out in this chapter using ...

获取价格

India - Mining Mineral Processing Equipment - export.gov

India possesses significant mineral resources, ranking among the top ten global producers of mica, barites, coal and lignite, iron ore, chromite, bauxite, and manganese. During 2018, India mined 95 different minerals from 1,531 mines. In 2017, India produced an estimated $17 million in minerals (excluding atomic minerals).

获取价格

20 Best Mining Companies In India (2023) - BizApprise

2023年4月12日 Also, India produces around 95 minerals with the reputation of being the 3rd and the 4th largest producer of coal and iron ore respectively. Talking about the market size as per FY22, Coal Production stood at 777.31 MT, Iron Ore Production stood at 204.48 MT, Crude Steel Production is 155 MT, and Aluminum Production stood at 3.82 MT.

获取价格