مسكن

>

limestone crusher specifications

مسكن

>

limestone crusher specifications

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

limestone crusher specifications

Limestone jaw crusher specifications - LinkedIn

5 之 Limestone jaw crushers are designed to handle a wide range of feed sizes and production requirements. The crushing capacity is typically measured in tons per hour (TPH) and varies depending on...

获取价格

进一步探索

Schematic diagram of limestone handling and dosing systemJaw Crusher PDF Download - YUMPULimestone Specifications (Composition) + Example (PDF) - Crusher Product Gradation Charts - Mineral Processing Correct Rock Size for Jaw Crusher Feed What do Jaw data-id="" >Williams Crusher

Rock Crushers Pulverizers Williams Crusher

What Is Rock Crushing Equipment Used for?How Do Rock Crushers Work?What Type of Rock Crusher Do I Need?Rock Crusher ApplicationsThe type of rock crusher required depends on moisture content, the hardness of the material, and your desired product size. Crushing may take place in one process with a single crusher. However, secondary and tertiary crushing can be used to further break your material down to the desired size. Many processing plants or rock crushing plants utilize...

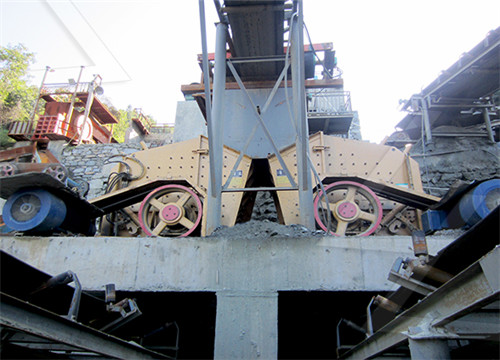

Crushing Technologies - thyssenkrupp Polysius

Discover our durable crushers on our landing page: crushing-technologies. The TITAN® Double-Shaft Hammer Crusher is used for crushing medium-hard rock. For wet

获取价格

Aggregate Stone Products - West Virginia Limestone Sandstone

Since 1997 our team at Hog Lick Aggregates has been providing North Central West Virginia with quality aggregate stone products. #8 AASHTO. #57 (1 inch) AASHTO. # 4 (1.5 Clean) AASHTO. # 3 (2 inch) AASHTO. # 1 (3 inch) AASHTO. R3

获取价格

selection and purchasing guide of hammer crusher

They are used for size reduction of hard to medium hard limestone, and sometimes for marl crushing. Hammer mills work with reduction ratios as high as 1 : 60; depending on the crusher feed, this ratio can increase to 1

获取价格

What You Need to Know About Building Trails with Crusher Fines

2019年8月20日 An 8' wide contractor built crusher fine trail in the Denver area costs between $4 and $5 per foot, not including the cost of site preparation and infrastructure such as retaining walls, and bridges. This compares with $12 to $15 per linear foot for concrete. The fines cost about $3.00 per cubic yard delivered in the metro area.

获取价格

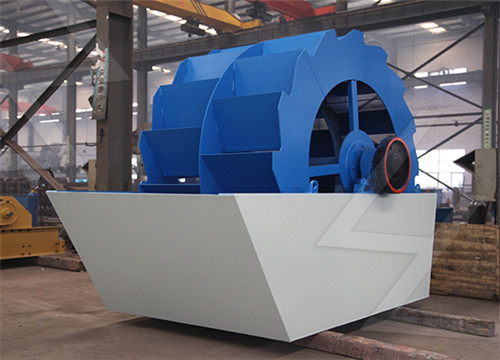

Limestone Crusher: An Edge Tool for Making Crushed Limestone

2023年7月11日 When crushing limestone with a mud content of less than 5% and a moisture content of less than 7%, choose a hammer crusher . Hammer crushers are the first choice for crushing soft to medium-hard rocks. Moreover, with small crushing cavity and well-sealed structure, hammer crushers solve the problems of dust pollution and powder

获取价格

Hammer Crusher Machine - Big Crushing Ratio And High Efficiency

The raw materials the hammer crusher for sale can crush include limestone, coal gangue, coal, pebble, limestone, gypsum, brick, ... Rotor specification(mm) Feeding size(mm) Output size(mm) Capacity(t/h) for crushing limestone: Motor power(kw) FHC-20: Φ800×400 <100: Average<3: 20: 30-37:

获取价格

5 Limestone crushers make benefits to limestone plant

2023年3月3日 Summary:The ideal limestone crusher on the market are limestone jaw crusher, limestone impact crusher, limestone cone crusher, limestone sand making machine, limestone mobile crusher. The crushed limestone particles has a variety of particle sizes and specifications to meet various construction needs, and is an essential

获取价格

titan® Double-Shaft Hammer Crusher - thyssenkrupp Polysius

The titan® Double-Shaft Hammer Crusher is used for crushing medium-hard rock. For wet limestone, wet marl, clay, chalk, gypsum and similar raw materials. It permits a large feed size and is capable of producing a clearly defined finished product size being preselected by the gaps of the discharge grate and therefore able to produce fedd ...

获取价格

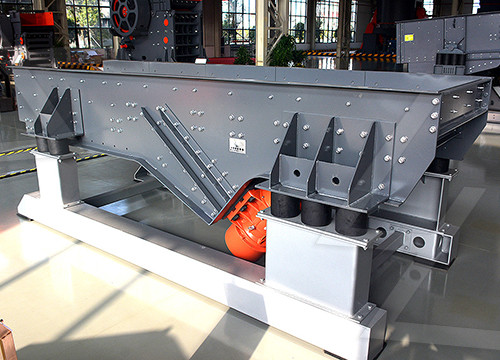

Suggested Compaction Standards for Crushed Aggregate

Suggested Compaction Standards for Crushed Aggregate Materials Based on Experimental Field Rolling F.P. NICHOLS, Jr. and HAL D. JAMES, respectively. Highway Research Engineer, and Highway Engineer Trainee, Virginia Council of Highway Investigation and Research, Charlottesville This paper describes field studies undertaken

获取价格

Crusher Run - What is it? - Gravelshop

It may often look like sand, though it is actually part of the process of crushing limestone, granite or whatever is local to your market for coarse aggregates. Crusher run weighs approximately 2,500 lbs. per cubic yard. The depth of the crusher run base recommended in inches will vary depending on the project. What is Crusher Run used for?

获取价格

The Art of Building Crushed Stone Trails - American Trails

2023年4月7日 Arrowhead Trails, Inc. has built over 500 miles of natural surface trails since 1995. Their specialty is machine-built, 48" wide trails for mountain bikers, runners, and hikers. Even though 95% of their new construction is with native soils, they are receiving more requests for soft surface, accessible trails built with 3/8" minus crusher fines ...

获取价格

The Rebel Crusher - Crush, Screen and Track - RR Equipment

The Rebel Crusher Jaw is designed to crush concrete with rebar and wire. The Rebel Crusher’s feed system is specifically designed to feed large slabs and chunks of concrete. Nobody produces better looking crushed concrete! The REBEL CRUSHER hits the CA. DOT spec for crushed concrete in one pass!

获取价格

How to commission a limestone crusher first? - LinkedIn

2023年2月2日 Additionally, the crusher should be calibrated to the specifications of the limestone material being processed. cone crusher and mobile crusher To commission a limestone crusher, the following ...

获取价格

Do’s Don’ts Of Limestone Rock Crushing Mellott

2023年3月27日 Do’s: Use the right cone crusher parts to ensure efficient crushing. Inspect the limestone regularly for wear and replace worn parts immediately. Install appropriate guards in place to protect workers from hazardous machinery. Cone crushers are most effective when using the appropriate parts for their specific application.

获取价格

The Rebel Crusher - Crush, Screen and Track - RR Equipment

The Rebel Crusher Jaw is designed to crush concrete with rebar and wire. The Rebel Crusher’s feed system is specifically designed to feed large slabs and chunks of concrete. Nobody produces better looking crushed concrete! The REBEL CRUSHER hits the CA. DOT spec for crushed concrete in one pass!

获取价格

How to commission a limestone crusher first? - LinkedIn

2023年2月2日 Additionally, the crusher should be calibrated to the specifications of the limestone material being processed. cone crusher and mobile crusher To commission a limestone crusher, the following ...

获取价格

Do’s Don’ts Of Limestone Rock Crushing Mellott

2023年3月27日 Do’s: Use the right cone crusher parts to ensure efficient crushing. Inspect the limestone regularly for wear and replace worn parts immediately. Install appropriate guards in place to protect workers from

获取价格

McLanahan Double Roll Crushers

Double Roll Crushers. Double Roll Crushers typically follow a primary or secondary crusher and are used for secondary and tertiary reduction of various minerals, such as ROM coal, clean coal, limestone, gypsum, trona, shale, bauxite, oil shale, coke, salt, lime, glass, kaolin, brick, shale and wet, sticky feeds.

获取价格

McLanahan Hammermill Crushers

The Centerfeed Hammermill is a secondary crusher designed to accept feed from a primary with controlled top size ranging from 3" to 5" (75mm to 125mm). Industrial Hammermills are not limited to limestone or gypsum — they are known worldwide for processing bauxite, nickel ore, phosphate ore, coal, pet coke, clay, shale, and of course, limestone.

获取价格

Limestone Crushing Solution - Eastman Rock Crusher

If you want to further produce fine powder limestone products, use a jaw crusher, impact crusher or cone crusher to crush the raw ore and then use raymond mill to grind the product. The product fineness is 100-325 mesh. ... The stones meeting the particle size requirements are conveyed to the finished product pile, and the stones larger than ...

获取价格

Gravel Size Chart, Crushed Stone and Rock Sizes - Bovees, where

2023年7月21日 Crushed Gravel #2: Approx 1½ ″ to 3″ Wide. Crushed rocks in grade no. 2 usually range from 1½ inches to 3 inches in diameter, so, depending on your supplier, may contain larger gravel stones that, like #1, are not easy to work with and will need to be moved as individual pieces. Uses of gravel #2 include the following:

获取价格

Rock Crushers Pulverizers Williams Crusher

Call (314) 621-3348, email us at info@williamscrusher, or locate an agent near you. With industry-best rock crushers, you can reduce rocks of all types and sizes to your desired product size. Learn more about Williams Patent Crusher rock crushers.

获取价格

Size Grading Requirements for Coarse Aggregates

3. DelDOT = Delaware Department of Transportation specifications, Section 813 - Grading Requirements and Section 821 -Graded Aggregates. (CR-1 is referred to as Type A, Crusher Run is Type B; both require LA Abrasion < 45%) 4. AASHTO = American Association of State Highway Transportation Officials

获取价格

LT CRUSHING SOLUTIONS – LT Construction Mining

SPECIFICATIONS. Salient Features. Large capacity range. Custom made plant layouts to meet site specific requirements. Rugged design proven technology. Operation Successfully in Various mineral application. Limestone Crushing Plant supplied to all Cement Plants. Standard Attachments. Apron Feeder.

获取价格

Crushing Limestone Impact Jaw Crushers RUBBLE MASTER

The RM V550GO! is an impactor designed for difficult applications, so that you can reduce your machine investments and increase your profits. Primary crusher, secondary crusher and screener in one machine. Jaw Impact Crushers to Crush Limestone Regardless of your mining volume, RUBBLE MASTER has a crusher for you. RM 100GO!

获取价格

7 Different Crushed Stone Sizes and Their Applications - ReAgg

2020年7月27日 This material is a great choice for railroad projects and those that require drainage. #5 – Crushed stone #5 is 1 inch or smaller in size. This material is perfect for road and paver base. #8 – These stones are between 3/8 and 1/2 inch long. It is the most common stone used for concrete mixes. #10 – Crushed stone #10 is known as ...

获取价格

7 Different Types of Stone Crushers: A Comprehensive Guide

2023年7月28日 1. Jaw Crushers. Source: . Initiating our exploration, the first stone crusher we encounter is the jaw crusher. This type of machine boasts a simplistic yet highly effective design, employing two jaws – one stationary and the other mobile – to accomplish the task of crushing. As the mobile jaw exerts force, the material lodged ...

获取价格