مسكن

>

pebble crusher belt feeders

مسكن

>

pebble crusher belt feeders

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

pebble crusher belt feeders

Belt Feeders – MEKA

6 行 Belt feeders are used to feed smoothly flowing materials with a maximum size of 120 mm. They can ...

获取价格

Feeders - MEKA

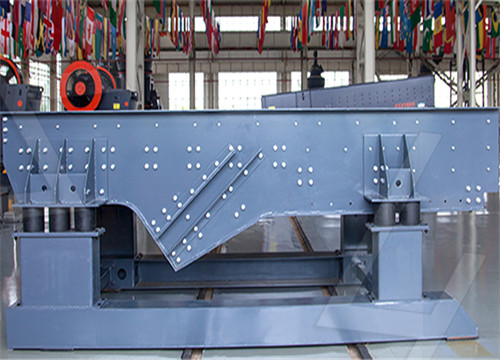

Vibrating Feeder. The design and wide size range of MEKA vibrating feeders is adapted to make proper access around crushers possible and decrease the total cost of the installation. The versatile design can be

获取价格

Pebble Crushing - 911 Metallurgist

2018年7月19日 Cyclone feed density typically ranges between 63 and 68 percent solids. Cyclone pressure ranges between eight and ten psi. The

获取价格

Raptor® Cone Crushers for Mining and Aggregate -

for pebble crushing. RAPTOR® 900. Our R900 is dimensionally similar . to the R650 with the benefit of a . larger eccentric throw. Liner design makes the crusher suitable for

获取价格

Mining Mineral Processing - Schenck Process

Apron feeder Apron feeders Pre-leech Gravity thickener separators Gravity tailings pump box Induction furnace Kiln Stacker SAG mill To waste dump Vibrating feeder Pebble

获取价格

Pebble Crushing Solution - Eastman Rock Crusher

The first stage: coarse fine crushing The materials are uniformly fed by the vibrating feeder through the silo and transported to the jaw crusher for coarse crushing. After the coarse crushed materials are screened by the

获取价格

Reliable belt feeder to extract materials I

Our Belt Feeders are suited for applications in gold, copper, coal, zinc, alumina, bauxite, iron ore, limestone, lignite, rock, phosphate rock, salt, sand and more. They are robust,

获取价格

Pebble Crushing Circuit Design - 911 Metallurgist

2018年8月11日 RQD <70 >40 The ore or rock type is considered to be less competent and amenable to semi-autogenous grinding without a pebble crusher. ... The pilot plant was

获取价格

Pebble Crushing in SAG Mill Circuit - 911 Metallurgist

2018年7月21日 A vibrating screen was used to provide a mill discharge product separation at 19 mm (¾ in.). The minus 76 trail (-3 in.) plus 19 mm (+¾ in.) screen oversize product, which are the “pebbles”, were then

获取价格

Crushers, breakers and grinding mills for the mining industry

Apron feeders and belt feeders; ... Ball mills, pebble mills, autogenous mills, and semi-autogenous (SAG) mills; Mill liners and feed chutes; Spare parts for crushers and mills, including jaw plates, side plates and blow bars; Belt conveyors; ... Selecting the correct crusher depends on ore characteristics such as abrasiveness, fragility ...

获取价格

Comminution and classification technologies of iron ore

2022年1月1日 The feed is <63 mm from a scalping screen undersize and secondary crusher product. The Arrium magnetite grinding circuit in Whyalla, South Australia, consists of two HPGR lines (1.4m diameter by 1.4 m long, with two 900kW motors) in closed circuit with a screen of 3 mm, fed with <32 mm feed from a three stage crushing plant.

获取价格

How industrial plants benefit from apron feeder magnetic

pecially for pebble applications. In the pebble crushing plants of the Chile’s Codelco Chuqui-camata, Pelambres, Esperanza mines and An-tamina in Perú, the shell of the pulleys are non-magnetic. Belt feeders are used more often at the dis-charge end of suspended electromagnets because apron feeders are historically more expensive

获取价格

Crushing Plant Design and Layout Considerations - 911

Crusher plug 160 2% of production time Chute plug 200 2.5% of production time Stockpile full 80 1% of production time Safety switch 200 2.5% of production time Metal on belt 52 Approx. 1 hr/wk Belt repair 240 3% of production time Electrical 200 2.5% of production time Mechanical Repair 200 2.5% of production time Others 0

获取价格

The pros and cons of cone crusher applications - Quarry

2021年4月16日 5. Distribute the feed evenly. Crusher feed should be evenly distributed around the centre of the crushing chamber. Avoid feed segregation where the coarse new feed is on one side of the feed opening and the finer recirculated feed is on the opposite side of the feed opening. 6. Setting should be close to desired product size.

获取价格

Raptor® Cone Crushers for Mining and Aggregate -

for pebble crushing. RAPTOR® 900. Our R900 is dimensionally similar . to the R650 with the benefit of a . larger eccentric throw. Liner design makes the crusher suitable for handling anything from primary crusher feed down to pebble crushing duty. RAPTOR® 1100. The R1100 is specifically . designed to cope with the high . capacities demanded ...

获取价格

Crushing and Screening Agg-Net

2012年10月15日 These feeders perform the dual function of feeding/conveying as well as separating smaller material to bypass the primary crusher. The oversize materials are discharged from the feeder into the primary crusher. This machine has a range of speeds but cannot control the feed rate to the crusher as precisely as an apron feeder.

获取价格

Crushers - All crusher types for your reduction needs - Metso

There are two basic types of jaw crushers: single toggle and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation causes, along with the toggle plate, a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of ...

获取价格

Pebble Crusher River Stone Crushing Plant Rock Crusher for Sale

Most of the river pebble strength is above 150MPa. River pebbles with a diameter of more than 100mm account for 20% to 30% of the total. Due to a large amount of mud in the river, in order to reduce the difficulty and cost, the sediment must be removed before crushing. A simple screening tool was added to screen out the sediment.

获取价格

High Pressure Grinding Roll for advanced crushing

Pebble Crushing. Our HPGR is great at de-bottlenecking your problematic pebble circuit. You know how easy it is for hard pebbles to get caught in circulation, small enough to escape the mills but too large to make it through your screening process. Our solution is to crush the pebbles with a cone crusher and then feed them to an HPGR.

获取价格

Crushing Systems -

date ensure a strong and reliable crusher design. The TST is equipped with an efficient crushing motion, modular frame and a simple, low maintenance design to handle increasingly hard ores and remote site locations. Performance An often overlooked, but very important, characteristic of the single toggle jaw crusher is its kinematic design.

获取价格

Minerals Free Full-Text Crusher to Mill Transportation Time

2021年12月15日 Five belt feeders draw the piled ore from the bottom and feed a conveyor belt that transports the ore to one of the two main stockpiles. The main stockpiles are similar to the intermediate stockpile, but each with almost triple the capacity of the intermediate stockpile. ... continued by secondary pebble mills and a pebble crusher. The ...

获取价格

® HP900 - Metso Corporation - PDF Catalogs

Cone crusher ® HP900 With over 10,000 units sold, the ® HP Series cone crushers are well known throughout the mining and aggregate industries. The HP900 is a new addition to the historic range, built and based on class leading proven technology. The ® HP900 cone crusher features new benefits to streamline installation and

获取价格

Mobile Hopper Feeders - Astec

The mobile hopper feeder allows operators to directly discharge from wheel loaders, grab cranes or excavators, and eliminates the double handling of material on site. ... Processing this material may include reducing its size with a crusher, sizing the crushed material with a screen and conveying the material into different stockpiles.

获取价格

Crushing Systems -

date ensure a strong and reliable crusher design. The TST is equipped with an efficient crushing motion, modular frame and a simple, low maintenance design to handle increasingly hard ores and remote site locations. Performance An often overlooked, but very important, characteristic of the single toggle jaw crusher is its kinematic design.

获取价格

Minerals Free Full-Text Crusher to Mill Transportation Time

2021年12月15日 Five belt feeders draw the piled ore from the bottom and feed a conveyor belt that transports the ore to one of the two main stockpiles. The main stockpiles are similar to the intermediate stockpile, but each with almost triple the capacity of the intermediate stockpile. ... continued by secondary pebble mills and a pebble crusher. The ...

获取价格

® HP900 - Metso Corporation - PDF Catalogs

Cone crusher ® HP900 With over 10,000 units sold, the ® HP Series cone crushers are well known throughout the mining and aggregate industries. The HP900 is a new addition to the historic range, built and based on class leading proven technology. The ® HP900 cone crusher features new benefits to streamline installation and

获取价格

Mobile Hopper Feeders - Astec

The mobile hopper feeder allows operators to directly discharge from wheel loaders, grab cranes or excavators, and eliminates the double handling of material on site. ... Processing this material may include reducing its size with a crusher, sizing the crushed material with a screen and conveying the material into different stockpiles.

获取价格

MP 1000 and MP 800 Series Cone Crushers

Even wear in the crushing cavity avoids localized restriction of the feed opening, maintains a uniform crusher setting, and achieves consistent size reduction. The hydraulic motor and gear drive adjustment provides finer control of the setting: the setting can be easily adjusted under load to compensate for liner wear without turning off the feed.

获取价格

Minerals Free Full-Text Pre-Processing to Increase the ... - MDPI

2022年6月6日 The SABC, an acronym for Semi-Autogenous Ball mill pebble Crusher configuration, was adopted for the Sossego industrial grinding circuit under a nominal throughput of 1841 t/h for a product with an 80% passing size (P 80) of 0.21 mm . Accordingly, a long-distance conveyor belt conveys the primary crusher product to a

获取价格

Basalt Crushing Solution - Eastman Rock Crusher

Basalt crushing line flow. The processing of basalt is divided into three stages: coarse crushing by jaw crusher, medium and fine crushing by cone crusher and sand making and shaping by sand making machine. The first stage: coarse crushing. Large basalt materials are uniformly fed by the vibrating feeder through the silo, and then transported ...

获取价格

Grinding Circuit - an overview ScienceDirect Topics

Grinding circuits are fed at a controlled rate from the stockpile or bins holding the crusher plant product. There may be a number of grinding circuits in parallel, each circuit taking a definite fraction of the feed. An example is the Highland Valley Cu/Mo plant with five parallel grinding lines (Chapter 12 ).

获取价格

Autogenous and Semi-Autogenous (AG/SAG) Mills Brochure

And the product of the large AG/SAG grinding is either a finished size ready of processing, or an immediate size for further grinding in a ball mill, pebble mill, VERTIMILL® or a stirred media detritor (SMD). Grinding circuit design AG/SAG mills are normally used to grind run-offmine ore or primary crusher product. Feed size to the mill is ...

获取价格

Preheater-kiln lime calcining systems - Metso Corporation - PDF ...

Belt Feeders Brochure. 4 Pages. Wobble Feeders Brochure. 4 Pages. ... Pebble Lime Cooler Brochure. 4 Pages. Lime Hydration Systems Brochure. 8 Pages. Laboratory Equipment Brochure. ... Barmac® B Series™ Vertical Shaft Impact (VSI) Crusher Orange Series Rotor Brochure. 16 Pages. ® MP 2500 Cone Crusher Brochure.

获取价格

MC 100i EVO Mobile jaw crushers - Wirtgen Group

Thanks to the diesel direct drive, the MC 100i EVO is economical in consumption. Continuous Feed System (CFS) for optimal crusher feeding. Innovative crusher unblocking system for extremely short downtimes. Efficient and powerful D-DRIVE diesel direct drive. Easy control via menu-guided touch panel.

获取价格

Crushing and Screening Solutions Catalogue - Metso

Crusher throughput capacity, scalped feed material Crusher throughput capacity, non-scalped feed material Closed side setting 40 mm Closed side setting 40 mm Benefits of primary crushing with scalping • Better total capacity in all applications • Better wear part wear profile • Longer lifetime of wear parts • Better total economy • Lower risk of packing

获取价格

Feeding solutions - Metso

Metso Outotec Belt feeders are well known as a diverse feeding solution to fit in a wide range of applications. This includes reverse operations and can even play a key role in crushing systems, tailings operations and many others. Robust design Metso Outotec Belt feeders are built robust and customizable to fit the exact need for the project.

获取价格

Dynamic modeling and simulation of a SAG mill-pebble crusher

2018年10月1日 The dynamic behavior of the plant circuit has been investigated emphasis on different cone crusher settings. Three numerical examples have been demonstrated in the paper. The first simulation was a typical SAG-cone crusher circuit. It tested the dynamic response of AG/SAG model with feed size data, flow rate, in mill transportation,

获取价格