مسكن

>

brief notes on cone crusher and jaw crusher

مسكن

>

brief notes on cone crusher and jaw crusher

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

brief notes on cone crusher and jaw crusher

Jaw Crusher vs Cone Crusher: A Comparison - Sepro Crushing and

While cone crushers and jaw crushers both perform a similar job of breaking rocks, their approach and applications are quite different. Introducing The Jaw Crusher These burly

获取价格

A Detailed Overview of Cone Crushers and What You

2020年6月3日 Crushers come in a variety of different styles and configurations, including jaw crushers, impact crushers and cone

获取价格

What Are Jaw Crushers and How Do They Work?

2019年3月28日 In a double-toggle jaw crusher, the moving crusher jaw is driven by the eccentric shaft that moves the front and rear toggles up and down. Each shaft revolution causes the moving crusher jaw to close at

获取价格

Mathematical Modeling and Multi-Criteria

2023年5月17日 When determining the rational profile of the jaw, the main requirement is the ability to capture a piece of rock having a maximum size d max (approximately 300 mm for mine crushers), and keeping the piece

获取价格

Jaw Crusher Explained - saVRee

Cone Crusher; Crusher Types (jaw, cone, gyratory) Typically, the initial crushing stage is completed using either gyratory crushers or jaw crushers. It is often the case that there will be only one crusher

获取价格

Jaw Crusher vs Cone Crusher: A Comparison - Sepro Crushing

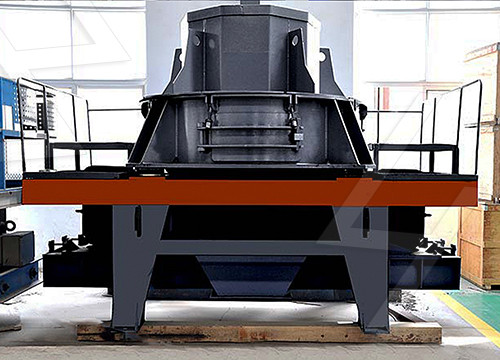

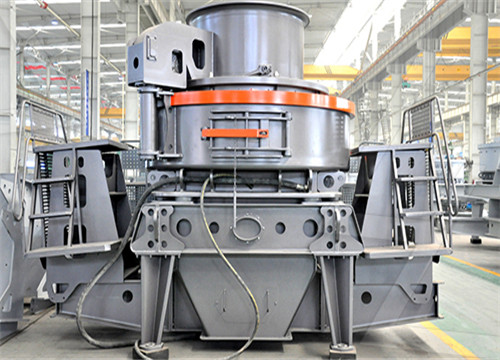

Cone crushers take care of secondary and tertiary crushing applications. Fine and medium-sized aggregates (used in asphalt and concrete, for example) are created by an eccentrically rotating shaft that grinds the rocks between a robust metal cone and a fixed wall. The Blackhawk 100 Cone Crusher is an example of a powerful cone crushing machine.

获取价格

Crushing 101 – Different types of crushers for distinctive needs

2020年12月17日 Jaw crushers can be divided into two basic types, single and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation, along with the toggle plate, causes a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top

获取价格

Stone Crushers: A Technical Review on Significant Part of

2022年5月14日 The operating parameters like eccentric speed of jaw crusher, throw, power draw, closed Side Setting in cone crusher affect the energy efficiency of crushing plant. Stone properties may affect the performance of crusher. The crusher performance can be improved by applying different experimental, analytical and numerical techniques.

获取价格

Crushers - All crusher types for your reduction needs - Metso

There are two basic types of jaw crushers: single toggle and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation causes, along with the toggle plate, a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of ...

获取价格

Materials Free Full-Text Influence of Basalt Aggregate ... - MDPI

2023年1月8日 Their results indicated that rock aggregates produced from jaw-cone crushers indicated better aggregate shape properties than jaw–jaw crusher association. Last but not least, Diógenes et al. [ 39 ] noted that the jaw crusher produced coarse aggregates with a better combination of sphericity and angularity during the first crushing

获取价格

Stone Crushers: A Technical Review on Significant Part of

Jaw crusher Expt. + Nume FEM analysis can be used as a powerful tool for analyzing the failure of the component in jaw crusher 2013 Rusi´ nski et al. [16] Poland 3 Primary crusher Jaw crusher Expt. + Nume Regression analysis was done in order to find out the effect of mechanical properties ofrock onthespecific power utilization of jaw ...

获取价格

Selecting the right crusher for your operations - Quarry

2020年3月19日 Best suited for secondary crushing applications, cone crushers are designed to crush pre-sized materials, usually 100mm, 150mm or 200mm, depending on the size of the crusher. Cone crushers can form finished products down to 12mm or less. Like the jaw crusher, the cone crusher provides a relatively low cost crushing solution, but

获取价格

Crushing - KPI-JCI

The Pioneer Series from Kolberg-Pioneer, Inc. represents the very latest in jaw crusher technology. Engineered to be the highest capacity jaw crusher on the market, the Pioneer Jaw Crusher will deliver up to 25% more tons per hour than other comparable jaw crushers. Pair that with heavy-duty flywheels for reduced horsepower

获取价格

Understanding Effects of Crushing Mechanism on Aggregate

2019年10月25日 In the present study, the effects of two different crushing operations (jaw-cone-vertical shaft impact (VSI): JCV and jaw-horizontal shaft impact (HSI): JH) on coarse aggregate morphology were studied. Angularity, texture, sphericity and FE of three different sizes of coarse aggregates: passing a sieve of 19 mm and retaining a sieve of 12.5 mm ...

获取价格

Modeling and Improving the Efficiency of Crushing Equipment

2023年5月16日 The modeling of the jaw crusher using mathematical expressions has also been studied by a number of researchers. For example, in , the modeling is considered in the context of energy consumption, and in , in the context of process kinematics. Work proposes a fundamental model that serves as a universal tool for modeling jaw crushers.

获取价格

Size Reduction SpringerLink

2022年3月23日 The working of gyratory crusher is very much similar to a jaw crusher. It consists of a solid cone set on a revolving shaft within a conical or vertical sloped hollow casing as shown in Fig. 6.10. The solid cone revolves in a circular path without rotating, and when it approaches the casing surface, crushing takes place.

获取价格

Crushing - KPI-JCI

The Pioneer Series from Kolberg-Pioneer, Inc. represents the very latest in jaw crusher technology. Engineered to be the highest capacity jaw crusher on the market, the Pioneer Jaw Crusher will deliver up to 25% more tons per hour than other comparable jaw crushers. Pair that with heavy-duty flywheels for reduced horsepower

获取价格

Understanding Effects of Crushing Mechanism on Aggregate

2019年10月25日 In the present study, the effects of two different crushing operations (jaw-cone-vertical shaft impact (VSI): JCV and jaw-horizontal shaft impact (HSI): JH) on coarse aggregate morphology were studied. Angularity, texture, sphericity and FE of three different sizes of coarse aggregates: passing a sieve of 19 mm and retaining a sieve of 12.5 mm ...

获取价格

Modeling and Improving the Efficiency of Crushing

2023年5月16日 The modeling of the jaw crusher using mathematical expressions has also been studied by a number of researchers. For example, in , the modeling is considered in the context of energy

获取价格

Size Reduction SpringerLink

2022年3月23日 The working of gyratory crusher is very much similar to a jaw crusher. It consists of a solid cone set on a revolving shaft within a conical or vertical sloped hollow casing as shown in Fig. 6.10. The solid cone revolves in a circular path without rotating, and when it approaches the casing surface, crushing takes place.

获取价格

Downstream Crushing Options for Secondary, Tertiary and

2021年4月12日 Secondary crushers typically include (but are not limited to) Cone Crushers, Horizontal Shaft Impactors, Hammermills and Roll Crushers. Occasionally, a Jaw Crusher may be applied as a secondary crusher. Cone Crushers. Cone Crushers are compression-type crushers, which reduce material as it advances downward through

获取价格

Reduction Ratios in Crushing - Machinery Partner

Reduction ratio - 6:1. Jaw Crushers use pressure to break up very hard, flaky, and slabby rocks by passing them between a moving surface and a stationary one. They are generally used for primary crushing but also provide great results with secondary crushing. Jaw crushers are excellent for breaking up concrete, rock and asphalt.

获取价格

Aggregate Production Optimization in a Stone-Crushing Plant

2020年2月8日 Typically, cone crushers are used sometime after jaw crushers. They do have one significant disadvantage: They tend to produce more flake-shaped particles than do other crusher types . ... Note that a larger value reflects a better characteristic, as per the equation shown below: $$ {\text{SN }} = - 10 {\text{log }}\frac{1}{{n\sum y^{2} }}, $$

获取价格

Gyratory VS Jaw Crushers: Advantages Disadvantages - 911

2016年2月28日 Large receiving opening per dollar of investment. Shape of receiving opening favourable for blocky feed. This, plus point 1, give the jaw a definite advantage over the gyratory, except in the very large sizes, for handling rock of massive formation. The jaw crusher is more easily adjusted, to compensate for wear of liners.

获取价格

(PDF) Cone Crusher Performance - ResearchGate

2015年5月13日 Jaw, gyratory, cone and roller crushers are all examples of crusher machines that utilize form conditioned compression to achieve size reduction. There is an essential and important

获取价格

Minerals Free Full-Text The Effect of HPGR and Conventional

2023年8月15日 Comparative high pressure grinding rolls (HPGR) and cone crusher pilot-scale tests were conducted using Upper Group 2 (UG2) platinum-bearing ore in order to determine the impact of micro-cracks in HPGR products toward energy requirements in ball mills and the degree of liberation. The ball mill was fed with HPGR and cone crusher

获取价格

What Is a Cone Crusher and What Can It Do for You?

2021年1月10日 The cone crusher distinguishes itself from these other crushers by how it operates in processing material. Similar to the jaw crusher, a cone crusher relies on compressive force to break apart the material flowing through it. Characterized by its central conical crusher component known as the head, a cone crusher operates around a main

获取价格

TECHNICAL NOTES 5 CRUSHERS - 911 Metallurgist

The chief difference between cone and gyratory or jaw crushers is the nearly parallel arrangement of the mantle and the cone at the discharge end in the cone crusher. This is illustrated in Figure 5.2. Reduction ratios in the following ranges are common for cone crushers: 6:1 - 8:1 for secondaries 4:1 - 6:1 for tertiary and quaternary crushing.

获取价格

Jaw Crusher - an overview ScienceDirect Topics

The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation. The capacity is primarily a function of: 1. crusher design characteristics such as width and depth of the crushing chamber, 2. open and

获取价格

Aggregate Crushers, for Rock, Ore Minerals - Gilson Co.

Portable Crushers is a new line of Hammermill and Jaw Crushers that offer rugged construction, portability, and versatility of use. All can be equipped with gasoline or electric power. Marcy® Lab Cone Crusher is ideal for reducing aggregates and mineral ores. The Marcy® GY-Roll 6in (152mm) or 10in (254mm) Lab Cone Crushers have 300lb per hour ...

获取价格