منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

jaw gyratory compact

Jaw Gyratory Crusher Pro

The Jaw Gyratory Crusher Pro combines all the advantages of a common gyratory crusher, including: Hydraulic adjustment of crushing gap to compensate for wear;

获取价格

进一步探索

Gyratory VS Jaw Crushers: Advantages DisadvantagesThe Gyratory Crusher Operation - YouTubeThe Advantages and Disadvantages of Gyratory CrusherGyratory Crusher Animation - YouTubeJaw Crusher PDF Download - YUMPU

Product datasheet Jaw Gyratory Crusher BK 63-75 Pro

Jaw Gyratory Crusher Pro – the next generation of underground crushing. The main characteristic of jaw gyratory crushers is their enlarged feed opening, which is located on

获取价格

How Does a Jaw Crusher Work Jaw Crusher Kemper Equipment

What Is A Jaw Crusher?How Does A Jaw Crusher Work?Which Are Better, Jaw Or Cone Crushers?How Can I Find The Best Crushers For My Operations?While jaw crushers may always be a smart primary crusher stage choice for many operations, it’s true that newer cone crushers are increasingly taking their place due to versatility. Cone crushers and jaw crushers both work by compression, reducing materials by squeezing them until they break apart. The benefit that cone crushers offer over jaw crus...

Industrial Solutions Gyratory crushers - ThyssenKrupp

Below: BK 63-75 jaw gyratory crusher installed underground in a copper ore crushing plant. Throughput 2,000 t/h Product P80 ≤ 150 mm Feed size in block caving max. 2,000 x

获取价格

alat industri kimia Crusher - BAB II TINJAUN PUSTAKA

Keuntungan Dodge Jaw Crusher: Titik engsel yang berada dibawah dan bagian atasnya yang bergerak maju mundur menghasilkan output yang

获取价格

Buyer's Guide: Crushers - Equipment Contracting

2021年1月11日 Both jaw crushers and gyratory crushers are still used today. Job Requirements. ... They offer a wide variety of jaw, cone, and impact crushers. Their model is a compact, mobile unit

获取价格

primary crusher tk model kb 63 75 Mining Quarry Plant

2013年4月22日 technical data of gyratory crushers – kefid Mining. Jaw and Gyratory crushers are two most important types of primary crushers crusher type [Zoll] KB 35- 67 KB 54- 75 KB 63- 75 . Crusher Technical Data: Model .

获取价格

Crusher - Wikipedia

Crusher. A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore ), so that pieces of different ...

获取价格

Types of Crushers: What You Need to Know - Machinery Partner

26'' X 14'' Compact Tracked Jaw Crusher. Crushers. Screeners. ST Ultra. Screen Titan . 10' x 4' Wheeled 3-way Screener. Screeners. Screeners. TD230. Gorilla. ... Cross section of a Kleeman primary jaw crusher Gyratory crushers. Run of mine material is transferred into a gyratory crusher’s upper-level hopper. The walls of the gyratory crusher ...

获取价格

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW

2017年6月30日 A review on the design and operations challenges of a single toggle jaw crusher is presented. Strength and fracture toughness of the material to be crushed are intrinsic properties that determine ...

获取价格

How Does a Jaw Crusher Work Jaw Crusher Kemper Equipment

The exact crushers you need—jaw, cone, impact, or gyratory—will depend on your site, the product you’re making, and how much you need to produce. ... More compact than double toggle designs, the single toggle movement jaw crusher was at one time unable to accept such large feed sizes, though it can typically run faster.

获取价格

Difference Between Gyratory Crusher Cone Crusher? Mellott

2022年9月19日 Gyratory crushers are better for larger materials crushing. Gyratory crushers are better at crushing large boulders while cone crushers are better at handling smaller rocks. Cone crushers are more affordable. Gyratory crushers tend to be more expensive but can crush more material in a single pass. Cone crushers are less

获取价格

Crusher, Crushing plant - All industrial manufacturers

jaw crusher BR380JG-3. mobile. Capacity: 50 t/h - 240 t/h. Motor power: 159 kW. Opening height: 1,065 mm. Eco-friendly performance moving to a new stage. The operating weight of the BR380JG-3 ranges from 33,500 to 35,310 kg, with a maximum crushing capacity of

获取价格

Jaw crusher EB

Thanks to the optimised crusher speed and generously dimensioned fly wheels our Jaw Crusher EB series accounts for 25% lower energy cost compared to the competitors in the market. Lower energy consumption. Reinforced front and back wall. Additional outer reinforcing ribs to coincide with the lines of force. Swing jaws made of heavy-duty materials.

获取价格

Comminution 1-primary crushers PPT - SlideShare

2021年5月17日 Two types of primary crushers are available: Jaw Crushers and Gyratory Crushers. Gyratory crushers can produce 600 to 6000tph, depending on size. Whereas, jaw crushers top out around 750 tph. 1.1 Jaw Crushers; • Depending on different ways of moving, jaw crushers are divided into four types: 1. Blake jaw crusher, 2.

获取价格

Jaw crusher PPT - SlideShare

2014年12月9日 18. • Single Toggle Jaw Crusher • In the single toggle jaw crushers, the swing jaw is suspended on the eccentric shaft which leads to a much more compact design than that of the double toggle jaw crusher. • The swing jaw, suspended on the eccentric, undergoes two types of motion- swing motion towards the fixed jaw due to the action of

获取价格

The Rebel Crusher - Crush, Screen and Track - RR Equipment

The Rebel Crusher Jaw is designed to crush concrete with rebar and wire. The Rebel Crusher’s feed system is specifically designed to feed large slabs and chunks of concrete. Nobody produces better looking crushed concrete! The REBEL CRUSHER hits the CA. DOT spec for crushed concrete in one pass!

获取价格

Fine Jaw Crushers -

Jaw Gyratory Crusher PRO kubria® Cone Crusher Linebacker® Crusher Liner Epoxy ... For a compact crusher, our JC1250 can handle a high workload – up to 5 kg samples comfortably. It has impressive throughput – up to 140 kg/hr. With a heavy duty 7.5 kW electric motor, JC1250 equals that of our JC2501, but with half the crushing chamber

获取价格

Comminution 1-primary crushers PPT - SlideShare

2021年5月17日 Two types of primary crushers are available: Jaw Crushers and Gyratory Crushers. Gyratory crushers can produce 600 to 6000tph, depending on size. Whereas, jaw crushers top out around 750 tph. 1.1

获取价格

Jaw crusher PPT - SlideShare

2014年12月9日 18. • Single Toggle Jaw Crusher • In the single toggle jaw crushers, the swing jaw is suspended on the eccentric shaft which leads to a much more compact design than that of the double toggle jaw crusher. •

获取价格

The Rebel Crusher - Crush, Screen and Track - RR Equipment

The Rebel Crusher Jaw is designed to crush concrete with rebar and wire. The Rebel Crusher’s feed system is specifically designed to feed large slabs and chunks of concrete. Nobody produces better looking crushed concrete! The REBEL CRUSHER hits the CA. DOT spec for crushed concrete in one pass!

获取价格

Fine Jaw Crushers -

Jaw Gyratory Crusher PRO kubria® Cone Crusher Linebacker® Crusher Liner Epoxy ... For a compact crusher, our JC1250 can handle a high workload – up to 5 kg samples comfortably. It has impressive throughput – up to 140 kg/hr. With a heavy duty 7.5 kW electric motor, JC1250 equals that of our JC2501, but with half the crushing chamber

获取价格

What is a Primary Crusher? - more

27" 16" Compact Tracked Jaw Crusher. Crushers. Crushers. J1065T. Omega. 40" 26" Tracked Mobile Jaw Crusher. Crushers. Screeners. FS-104. ARK. ... Inside the jaw box of a jaw crusher Gyratory crushers. Gyratory crushers can be used for both primary and secondary crushing. They are similar to cone crushers as they both have cone-shaped

获取价格

Industrial Solutions Gyratory crushers - ThyssenKrupp

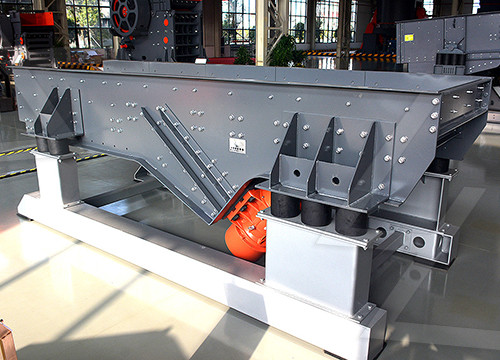

Jaw gyratory crushers – design and operating principle Technical data The main characteristic of jaw gyratory crushers is their enlarged feed opening which is located on one side of the crusher only. It is normally serrated and, to- gether with the upper part of the mantle, it forms the initial crushing zone. The

获取价格

AASHTO T 312 - Standard Method of Test for Preparing

2019年1月1日 This standard covers the compaction of cylindrical specimens of asphalt mixtures using the Superpave gyratory compactor. This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns associated with its use. It is the responsibility of the user of this standard

获取价格

New Used Primary Gyratory Crushers for Sale Crushing Equipment

Screens. Address: Box 176, Savona, B.C., Canada, V0K 2J0. Phone: +1 (250) 373-2424. Fax: +1 (250) 373-2323. Email: sales@savonaequipment. Savona Equipment is your source for New, Used, and Reconditioned Gyratory Crushing Equipment of many types and brand for large primary ore crushing, secondary, and tertiary fine material as well as ...

获取价格

Crushers - All crusher types for your reduction needs - Metso

Jaw crushers, gyratory crushers, and cone operate according to the compression principle. Impact crushers, in turn, utilize the impact principle. Jaw crushers . Jaw crushers are mainly used as primary crushers. Their main purpose is to reduce the material to a small enough size that it can be transported by conveyors to the next crushing stages.

获取价格

Laboratory and pilot plant Primary Jaw Crushers -

The Essa JC1000 Jaw Crusher is the smallest of the range. It is a medium-duty, entry-level machine designed for crushing smaller samples across a wide range of applications. Known in the industry as a steady-going and reliable machine, it is productive and hardy, with reduced operating and spare parts costs. Simple and compact design

获取价格

Crusher Close Side Settings - 911 Metallurgist

2016年1月17日 The maximum feed size is approximately 8 0% of the feed opening. The open side setting is measured when the crusher is at rest. The setting is measured either top to top, or bottom to top, depending on the tooth profile of the jaw dies. The closed side setting can be calculated by deducting the stroke from the OSS.

获取价格

thyssenkrupp Industrial Solutions wins further order for gyratory ...

2019年12月9日 Third order for a gyratory crusher awarded to thyssenkrupp in Australia within the last 12 months. thyssenkrupp has been awarded a contract to supply a new primary jaw gyratory crusher for the Roy Hill iron ore Mine in Western Australia. Located 340 kilometres south-east of Port Hedland, Roy Hill is a world-class iron ore operation

获取价格

Retsch : 产品 : 粉碎设备 : 颚式粉碎仪

颚式研磨仪应用领域. A jaw crusher is always at the very front of the sample preparation chain, precrushing all hard and brittle materials. The RETSCH jaw crusher range is primarily used in laboratories and pilot plants under rough conditions but are also suitable for on-line quality control of raw materials. The main fields of ...

获取价格

Selecting the right crusher for your operations - Quarry

2020年3月19日 Best suited for secondary crushing applications, cone crushers are designed to crush pre-sized materials, usually 100mm, 150mm or 200mm, depending on the size of the crusher. Cone crushers can form finished products down to 12mm or less. Like the jaw crusher, the cone crusher provides a relatively low cost crushing solution, but

获取价格