مسكن

>

highway industry jaw crusher crusher

مسكن

>

highway industry jaw crusher crusher

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

highway industry jaw crusher crusher

Jaw crusher EB

Our Jaw Crusher EB series has a rugged and reliable design that’s ideal for high capacities, while also offering low wear and tear and easy maintenance. The EB Pro series is

获取价格

进一步探索

Jaw Crusher Handbook Stone Crusher PDF - JXSC MineCorrect Rock Size for Jaw Crusher Feed What do Jaw Gyratory VS Jaw Crushers: Advantages DisadvantagesJaw Crusher PDF Download - YUMPUHow A Jaw Crusher Works - YouTube

Hydra-Jaw® Crushers - Astec

The Hydra-Jaw ® crushers combine the most advanced jaw crushing technology with our years of experience and expertise. The highly-productive Hydra-Jaw ® crushing line is

获取价格

进一步探索

H2238 Hydra-Jaw From: Telsmith Inc. - Astec Industrieshybrid jaw crusher tracked hybrid crusher mobile jaw data-id="" >Superior Industries

Jaw crusher, Jaw crushing and screening plant - All

stationary primary secondary. Capacity: 11 t/h - 30 t/h. Motor power: 11 kW - 30 kW. Jaw Crusher is widely used in mining, smelting, building materials, roads, railways, water conservancy and chemical industries.It is suitable

获取价格

Types of Crushers: What You Need to Know - Machinery Partner

The Gates’ gyratory crushers were preferred by the mining industry for almost two decades until the turn of the century, circa 1910, when Blake’s jaw crushers saw a resurgence in popularity. The demand for large-mouthed jaw crushers skyrocketed as the industry began to understand their potential as primary crushers in rock quarries.

获取价格

Mining Equipment Rock Crushing Goldbelt Global Charlotte

Goldbelt Global mining crushing equipment, mineral processing, pilot testing, recycling environmental sustainability, landscaping, gold and silver recovery.

获取价格

Downstream Crushing Options for Secondary,

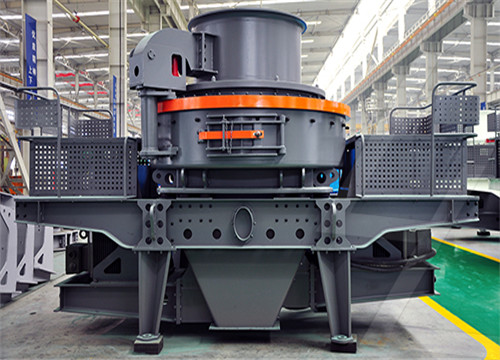

2021年4月12日 The rock breaks and falls out the bottom. These types of crushers are usually applied as tertiary or quaternary crushers with less than 2” (75 mm) feed or smaller. Some Vertical Shaft Impactors can be

获取价格

Choosing a mobile impact crusher for recycling – what you

2021年3月12日 Mobile impact crushers, also known as the tracked impact crusher or recycling impactor, are recognizable mainly due to the fact that these crushers are mounted on a tracked undercarriage. Overall range of capacity for mobile impact crushers is roughly about 100 to 500 tons per hour. Today's mobile impact crushers are especially ideal for ...

获取价格

Jaw Crushers Price - Made-in-China

A. The cost of a Jaw Crushers Price can vary widely depending on its size, capabilities, and complexity. Most of the price of Jaw Crushers Price ranges from US $ 516 to $ 450000 per Set. It's important to research and compare different models and features to find the best Jaw Crushers Price for your needs and budget. Q.

获取价格

Stone Crusher For Sale - Produce High-quality Aggregate

Used to process aggregate. The stone crusher can process the production of building aggregates, cement concrete, highway materials, cushion materials, and other aggregates. In these industries, we often see the use of stone crushers and sand making machines together. 2. Applied in infrastructure construction.

获取价格

5 Common Questions about Jaw Crushers Answered

2019年5月30日 Jaw crushers have a multitude of advantages, including: Ability to handle many different types of materials—from hard granite to reclaimed asphalt pavement (RAP) and more—without displaying as ...

获取价格

Concrete aggregates properties crushed by jaw and

2019年1月1日 The coarse aggregates obtained by different crushing mechanisms (jaw and impact crushers) show very similar characteristics in terms of binder content assessed by acid leaching (27.5 and 26.6 wt.%), water absorption (8.76 and 9.75 wt.%) and porosity (18.6 and 20.2 vol.%).Thus, it is not possible to conclude that any of these mechanisms are

获取价格

Mobile Crusher Plant - Cost-Saving, High Mobility, Safety

Three-in-one impact crusher mobile plant – APYL series. Processing capacity: up to 200tph. Configurations: 200Kw impact crusher + 1536 type return screen. Maximum feeding: 350 medium soft rock. Crushing materials: medium and soft rock and construction waste. Applications: construction aggregate or road construction.

获取价格

6 Stone Crushers In South Africa Save Time Money - ZENITH Crusher

2022年8月1日 Our stone crusher machine has been widely used in metal mining, metallurgical, chemical, construction, cement and sandstone industry in South Africa. The stone crusher we provide mainly includes: Jaw Crusher Sand Making Machine Cone Crusher Impact Crusher Hammer Crusher Mobile Crusher. 6 Type of Stone Crushers

获取价格

Types of Rock Crushers Quarry Crushing Equipment Kemper

Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing equipment types, though there can be overlap between primary and secondary crushers as far as suitable types. 2. Secondary Crushing.

获取价格

A Detailed Overview of Cone Crushers and What You Need to

2020年6月3日 The company was later acquired by the brand in 1999, and it has continued to produce industry-leading crushing equipment since then. Today, Cedarapids manufactures five different lines of cone crushers, offering nearly 20 crushers. ... Advantages of a Jaw Crusher. ... Caterpillar Signs Strategic Agreement with CRH for

获取价格

Stone Crushers: A Technical Review on Significant Part of

Keywords Stone crusher Jaw crusher Cone crusher Impact crusher Aggregate production 1 Introduction Crushers are widely used equipment to reduce the large size rocks into stones finer than about 50–100 mm in size [1]. In infrastructure industry, these equipment are available in different capacities ranging from 0.1 ton/hr. to 50 ton ...

获取价格

Impact Crusher VS Jaw Crusher:What Are the Differences?

2020年4月15日 Crushers' Application. 1) Jaw crusher is widely used in many fields such as mining, smelting, building, highway, railway, waterpower and chemical industry, crushing various materials with ...

获取价格

Types of Rock Crushers Quarry Crushing Equipment Kemper

Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing equipment types, though there can be overlap between primary and secondary crushers as far as suitable types. 2. Secondary Crushing.

获取价格

A Detailed Overview of Cone Crushers and What You

2020年6月3日 The company was later acquired by the brand in 1999, and it has continued to produce industry-leading crushing equipment since then. Today, Cedarapids manufactures five different lines of cone

获取价格

Stone Crushers: A Technical Review on Significant Part of

Keywords Stone crusher Jaw crusher Cone crusher Impact crusher Aggregate production 1 Introduction Crushers are widely used equipment to reduce the large size rocks into stones finer than about 50–100 mm in size [1]. In infrastructure industry, these equipment are available in different capacities ranging from 0.1 ton/hr. to 50 ton ...

获取价格

Impact Crusher VS Jaw Crusher:What Are the Differences?

2020年4月15日 Crushers' Application. 1) Jaw crusher is widely used in many fields such as mining, smelting, building, highway, railway, waterpower and chemical industry, crushing various materials with ...

获取价格

Coal crusher, Coal crushing plant - All industrial manufacturers

jaw crushing plant C6X100. stationary primary coal. Capacity: 80 t/h - 1,100 t/h. Motor power: 110 kW. Opening height: 760 mm. ... crushing equipment all over the world since the end of 20 century. Nowadays, the C6X Series Jaw Crushers has indisputably become the most popular jaw crusher in the world.

获取价格

Crushers and Screens – PT. Marton Tekindo Abadi

PV-Series jaw crusher is ’s latest Jaw Crusher design which is the culmination of many years of practical experience, advanced technology and advanced design instrumentalities. The PV-Series is widely used in various industries including mining, smelt, building materials, highway, railway, water conservancy, chemical industry ...

获取价格

7 Differences of Jaw Crusher - Eastman Rock Crusher

2022年3月8日 The jaw crusher of eastman can crush all kinds of materials with compressive strength not exceeding 250 MPa. It is widely used for the primary crushing of various ores and rocks in various fields such as mining, smelting, building materials, highway, railway, water conservancy and chemical industry, such as limestone, iron

获取价格

SCREEN MACHINE Screens and Crushers for Sale - Highway Equipment Company

Screen Machine is a leading manufacturer of portable jaw, impact and cone rock crushers, screening plants, trommels and conveyors, and is an industry leader in design and innovation. Based in Etna, Ohio, Screen Machine has been providing American-made crushing and screening innovation since 1966. Screen Machine products are

获取价格

Mobile Crushing Saves Time Money For Construction Pros

2021年11月22日 Kleeman. The construction industry is one of the largest recyclers in the country, recycling and reusing asphalt and concrete in massive amounts. Today's mobile crushers are ideal for use in a ...

获取价格

Keestrack to Develop Electric Crushers OEM Off-Highway

2016年8月9日 As part of its continuous development efforts, Keestrack is developing electrified jaw and cone crushers, as well as diesel-electric hybrid screeners and impactors. August 9, 2016. Keestrack N.V. The diesel-hydraulic drive modules with fuel efficient load-sensing technology are assembled on a work station parallel to the plant assembly.

获取价格

How to improve jaw crusher performance and productivity - Metso

2020年3月30日 That is why it needs to be monitored throughout the crusher’s lifecycle. As excessive wear can cause a 10–20% reduction in production, it is important to find the optimal time for the jaw turn or change in terms of cost and benefit. Again, with the same scenario with C130, we would have approximately a 70 stph reduction in production, in ...

获取价格

Reduction Ratios in Crushing - Machinery Partner

Jaw crushers are excellent for breaking up concrete, rock and asphalt. Jaw box in a jaw crusher Impact Crushers. Reduction ratio - 10:1. Impact Crushers can be used for either primary or secondary crushing and work by creating a sudden impact force that shatters the material into smaller pieces. They often come as primary crushers (with an 8:1 ...

获取价格

Selecting the right crusher for your operations - Quarry

2020年3月19日 Best suited for secondary crushing applications, cone crushers are designed to crush pre-sized materials, usually 100mm, 150mm or 200mm, depending on the size of the crusher. Cone crushers can form finished products down to 12mm or less. Like the jaw crusher, the cone crusher provides a relatively low cost crushing solution, but

获取价格

What Are Jaw Crushers and How Do They Work? Oreflow

2019年3月28日 In a double-toggle jaw crusher, the moving crusher jaw is driven by the eccentric shaft that moves the front and rear toggles up and down. Each shaft revolution causes the moving crusher jaw to close at the downstroke and open up during the upstroke. The toggle is kept in place by spring-loaded tension rod.

获取价格