منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

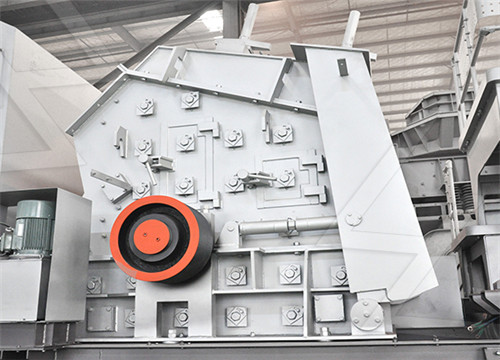

impact crusher masses

Impact crusher kinematics: The dynamics of an impact swing

Briefly described: In the crushing chamber of an impact crusher, particles (natural stone, mineral-based recycling material, or asphalt fragments – commonly with a relatively broad band of particle sizes, e.g. a distribution between 0 and up to 1000 mm) are thrown

获取价格

进一步探索

(PDF) A performance model for impact crushers - (PDF) Impact Mechanics - ResearchGateImpact Crusher PDF Industries Mechanical Engineering - Impact crusher structure, working principle and features(PDF) DESIGN OF MECHANICAL CRUSHING MACHINE -

SANDVIK 700 RANGE HORIZONTAL SHAFT IMPACTORS (HSI)

GETS THE JOB DONE - BOTH OF THEM. The all-new 700 range of Horizontal Shaft impact crushers ofers new levels of safety and eficiency. Developed to comply with new

获取价格

(PDF) Design of Impact stone crusher machine

2019年5月31日 The main objective is to design impact stone crusher. Impact stone crusher involves the use of impact rather than pressure to

获取价格

Impact Crusher - an overview ScienceDirect Topics

Hammer (impact) crusher: The feed is fragmented by kinetic energy introduced by a rotating mass (the rotor) which projects the material against a fixed surface causing

获取价格

A performance model for impact crushers - ScienceDirect

2002年10月1日 It can be applied to both hammer and vertical-axis impact crushers with the help of the corresponding estimations for the impact energy per unit mass. Here we

获取价格

Design of impact stone crusher machine - ResearchGate

impact stone crusher based on the type of arrangement of the impact rotor and shaft. a. Horizontal shaft impact stone crusher b. Vertical shaft impact stone crusher . 3.4

获取价格

Design and Random Vibrational Analysis of Horizontal Impact

2020年10月31日 All research works are done on the impact horizontal crusher through modeling in SOLIDWORKS, and Random Vibrational analysis was performed using

获取价格

Milling Studies in an Impact Crusher I: Kinetics Modelling

Abstract: A number of experiments were conducted on a laboratory batch impact crusher to investi-gate the effects of particle size and impeller speed on grinding rate and product

获取价格

Mobile Impact Crushers - RUBBLE MASTER

Mobile impact crushers are used to recycle concrete and asphalt and process natural rock. They are easy to move on and between job-sites, which allows operators to crush on smaller job-sites. Best of all they often

获取价格

Minerals Free Full-Text Milling Studies in an Impact

2021年3月20日 In impact crushers, the hammers or beaters on a rotating shaft transfer kinetic energy to the particles as they come in contact with them. This sends shock waves through the material and

获取价格

Design of impact stone crusher machine - ResearchGate

impact stone crusher based on the type of arrangement of the impact rotor and shaft. a. Horizontal shaft impact stone crusher b. Vertical shaft impact stone crusher . 3.4 Advantages of the ...

获取价格

A performance model for impact crushers - ScienceDirect

2002年10月1日 Attou et al. (1999) adapted this distribution as a classification function for impact crushers in the following form: (6) C i (d i)=1− exp − a Q s d i k E n where E (J/kg) is the average impact energy per unit mass, Q (t/h) is the feed rate; a and s depend on the specific crusher design and size; k and n are related to the material ...

获取价格

Modelling and simulation of particle breakage in impact crushers

2004年12月10日 Recall the size distribution model for crushers developed by Whiten (1972) and shown in Fig. 1.The particles are characterized by their size distribution that is represented in a discrete form by the vectors f (feed) and p (product), respectively. Each component of f and p represents the mass fraction of the corresponding size class in the

获取价格

Battle of the Primary Impactors: Andreas vs. New Holland

2022年1月18日 For an impact crusher to preform, it requires a large expansion, or explosion chamber, for material breakage. ... Because an impactor works on the theory of mass and velocity, increasing the speed will increase the work, resulting in a finer output. Increasing speed generally increases wear rates as well. Adjusting one less apron curtain

获取价格

Effect of Crushing Method on the Properties of Produced Recycled

2023年8月31日 The findings indicate that the use of impact crushers results in the production of RCA possessing more spherical geometric characteristics, albeit with a broader particle size distribution and a relatively higher content of fine particles as compared to those obtained from jaw crushers. ... They observed a variation from 20% to 40% (in

获取价格

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT CRUSHER

An impact crusher can be further classified as Horizontal impact crusher (HSI) and vertical shaft impact crusher (VSI) based on the type of arrangement of the impact rotor and shaft. Fig. 1 A typical Impact crusher [6] Horizontal shaft impact crusher These break rock by impacting the rock with hammers/blow bars that are fixed upon the outer ...

获取价格

Modelling and simulation of particle breakage in impact crushers

2004年12月10日 Section snippets Mass balance. Recall the size distribution model for crushers developed by Whiten (1972) and shown in Fig. 1. The particles are characterized by their size distribution that is represented in a discrete form by the vectors f (feed) and p (product), respectively. Each component of f and p represents the mass fraction of the

获取价格

Crusher Aggregate Equipment For Rent MachineryTrader

2023年8月29日 Kimball Equipment. Salt Lake City, Utah 84104. Phone: (801) 515-7410. visit our website. Email Seller Video Chat. 1 IP1313 Impact Crusher with THREE bar rotor with 5" Tool steel Impeller bars. 2 450 hp Tier 4 Final, enclosed Scania diesel engine, hydraulic clutch to crusher, and 150kW 460/3/60 generator, inc...

获取价格

(PDF) Design of Impact stone crusher machine - ResearchGate

2019年5月31日 Based on the mechanism used crushers are basically of three types; namely, Cone crusher, Jaw crusher, and Impact Crusher. The main objective is to design impact stone crusher. ... solid masses of ...

获取价格

® NP Series™ impact crushers - Metso

High performance. ® NP Series™ HSI crushers consist of heavy rotor, wear resistant materials, and an optimal crushing chamber design. This combination has proven revolutionary in improving capacity and product quality, as well as in reducing operating and wear costs. ® NP™ crushers have a unique blow bar attachment system.

获取价格

Modelling and simulation of particle breakage in impact

applied to both horizontal- and vertical-shaft impact crushers by means of the corresponding estimations for the average impact energy per unit mass presented here. We propose a new classification ...

获取价格

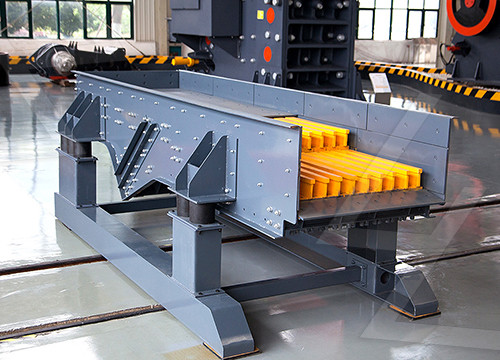

PQ University Lesson 7: Crushing Secondary Breaking

2019年9月2日 Impact crushers are capable of producing mineral aggregate mixes in one single crushing stage in a closed-cycle operation, making them particularly cost-effective. Different crusher units can alternatively be combined to process recycling material. A highly efficient method of processing recycling material combines crushing, screening and ...

获取价格

IMPACT CRUSHERS -

impact crushers can handle individual lumps of feed material up to 8 tons in weight and 3 m3 (100 cu.ft) in volume, effecting the comminution process in a single pass at capacities of over 2200 tons/hour. Even feed material with a high moisture content up to 15% H2O can be processed without any problems by the provision of indirect ...

获取价格

« DESIGN OF A STONES CRUSHER MACHINE» - rufso

Impact Crusher can deal with materials with the feeding size less than 500 mm and compressive resistance not more than 500 MPa despite the large, middle ... masses remain together after impact and move together after impact at a velocity of V2. Then from conservation of momentum m1u1 + m2u2= (m1+ m2) v

获取价格

Modelling and simulation of particle breakage in impact

applied to both horizontal- and vertical-shaft impact crushers by means of the corresponding estimations for the average impact energy per unit mass presented here. We propose a new classification ...

获取价格

PQ University Lesson 7: Crushing Secondary Breaking

2019年9月2日 Impact crushers are capable of producing mineral aggregate mixes in one single crushing stage in a closed-cycle operation, making them particularly cost-effective. Different crusher units can alternatively be combined to process recycling material. A highly efficient method of processing recycling material combines crushing, screening and ...

获取价格

IMPACT CRUSHERS -

impact crushers can handle individual lumps of feed material up to 8 tons in weight and 3 m3 (100 cu.ft) in volume, effecting the comminution process in a single pass at capacities of over 2200 tons/hour. Even feed material with a high moisture content up to 15% H2O can be processed without any problems by the provision of indirect ...

获取价格

« DESIGN OF A STONES CRUSHER MACHINE» - rufso

Impact Crusher can deal with materials with the feeding size less than 500 mm and compressive resistance not more than 500 MPa despite the large, middle ... masses remain together after impact and move together after impact at a velocity of V2. Then from conservation of momentum m1u1 + m2u2= (m1+ m2) v

获取价格

Crusher Aggregate Equipment For Sale MachineryTrader

2023年8月29日 Impact crushers, sometimes called “hammer crushers,” use mass and velocity to break up pieces with a blow bar or hammer that strikes a stationary plate. When the rock hits the plate or anvil, it breaks on natural stress lines to create a uniform product. Find The Right Crusher.

获取价格

Numerical Simulation of a Single and Double-Rotor Impact Crusher

2021年11月12日 However, the energy associated with the double impeller impact crusher is much higher and energy intensification, rather than energy efficiency, is the main gain of the double impeller design. ... where m is the mass of the smallest and lightest particle (kg) and K is the particle normal stiffness. In our experience, it was found that a smaller ...

获取价格

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT

The Impact Crusher Machine rotor revolves in fixed direction by means of driving action of triangle belt that connects with motor. Above rotor, there are sets of suspended impact plates. ... Fig.3 Scheme of breaking process in crusher [1] Mass Balance (Size distribution) According To size distribution model given by whiten (1972) ...

获取价格

Size Reduction – Visual Encyclopedia of Chemical Engineering

General Information/Equipment Design. Size reduction in impact crushers occurs through particle concussion by rigid forces. The hammer crusher, also called the hammer mill, is an example of an impact crusher. In hammer crushers, hammers swing freely on a disc mounted on the main shaft within the device.

获取价格

Jaw Crusher - an overview ScienceDirect Topics

Percussion crusher: The aggregates are produced by impact and hence higher fines content. • Hammer (impact) crusher: The feed is fragmented by kinetic energy introduced by a rotating mass (the rotor) which projects the material against a fixed surface causing it to shatter causing further particle size reduction. This crusher produces more ...

获取价格

Impact Crusher Description Advantages - Engineering Intro

2012年8月15日 If crushers that used pressure force is used then it results in unpredictable and even more uneven, jagged shape particles. Therefore, use of VSI crusher results in more cubical and even shapes particles. This is so, because vertical shaft impactor crusher utilizes the velocity force that is applied evenly to the surface and the mass of rock.

获取价格

Construction Working and Maintenance of Crushers for

dynamic impact. When the material is crushed in an impact crusher, the freely falling material first breaks due to dynamic impact by a moving hammer and then the force of impact accelerates movement of the reduced particles toward breaker blocks and/or other hammers for further size reduction. Dynamic impact has specific advantages for the ...

获取价格

Dust emission from crushing of hard rock aggregates

2019年3月1日 The mass concentration of coarse particles varied from few tens of μg/m 3 to over 6 × 10 3 μg/m 3 downwind from the crusher. The mass concentration of fine particles (PM 2.5 and PM 1) ranged between ten μg/m 3 and few hundreds of μg/m 3 downwind from the crusher. Fine particles originate mainly from the machinery used in

获取价格

Numerical Simulation of a Single and Double-Rotor Impact

2022年1月25日 horizontal impact crusher by both Djordjevic et al. [10] and Schubert et al. [11], albeit with a few particles and simplified geometries. Cunha et al. [12] investigated the distribution ... where m is the mass of the smallest and lightest particle (kg) and K is the particle normal stiffness. In our experience, it was found that a smaller time ...

获取价格

Crusher Aggregate Equipment For Sale in Canada - MachineryTrader

2024年1月15日 Impact crushers, sometimes called “hammer crushers,” use mass and velocity to break up pieces with a blow bar or hammer that strikes a stationary plate. When the rock hits the plate or anvil, it breaks on natural stress lines to create a uniform product. Find The Right Crusher.

获取价格