مسكن

>

tertiary impact crushers

مسكن

>

tertiary impact crushers

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

tertiary impact crushers

Tertiary Impact Crusher HTI -

TERTIARY IMPACT CRUSHER HTI 1) VR2-Rotor, weight without grinding path 2) VR4-Rotor, weight with grinding path

获取价格

IMPACT CRUSHERS -

Tertiary Impact Crusher HTI Designed specifically for the Recycling and Aggregates industries, the modular HTI series of Tertiary Impactors was designed for

获取价格

进一步探索

Impact Crusher Working Principle - Mineral Processing APS Secondary Impactor Hazemag North America

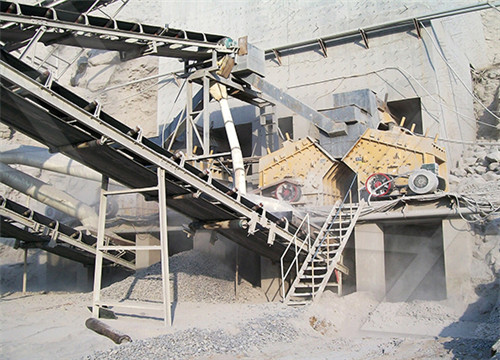

Tertiary Impact Crushers - Constmach

CONSTMACH Tertiary Impact Crusher is ideally suited to crush medium-hard, non-abrasive materials down to a cubical, well graded product size of 0 ֠5 mm (60% passing)

获取价格

variopactor® impact crusher manufactor

The variopactor ® as tertiary impact crusher it is the latest development in thyssenkrupp's processing portfolio -- a development resulting from the requirements of our customers and characterized by high reliability, which

获取价格

The Complete Guide to Primary Crushing, Secondary

2023年2月28日 Working Principle of Tertiary Crushers. The working principle of tertiary crushers varies depending on the type of crusher, but generally, they work by applying pressure to the material through

获取价格

® NP Series™ impact crushers - Metso

® NP Series™ horizontal shaft impact (HSI) crushers are known for high reduction ratios when processing all type materials. They deliver unbeatable performance in primary, secondary and tertiary crushing in aggregates production, mining operations, as well as recycling applications.

获取价格

Portable Tertiary Impact Crushers - MEKA Concrete Plants

Portable Tertiary Impact Crushers are wheel-mounted rock crushing machines, engineered for tertiary crushing applications. Equipped with a horizontal shaft impact crusher and a feed hopper with belt feeder, it is designed especially for processing soft and medium-hard materials, such as limestone and recycled materials, and ideal for the

获取价格

PQ University Lesson 7: Crushing Secondary Breaking

2019年9月2日 SECONDARY/TERTIARY MOBILE CRUSHERS. Secondary impact crushers and cone crushers are used to further process primary-crushed aggregate, and can be operated with or without attached screening units. These crushers can be used as either secondary or tertiary crushers depending on the application. When interlinked to

获取价格

Tertiary crusher, Tertiary crushing and screening plant - All ...

tertiary crushing and screening plant CKT-PDK series. impact mobile primary. Capacity: 150 t/h - 950 t/h. Motor power: 400, 315, 160, 250, 200 kW. Tertiary impact crushers are used for soft and medium-hard materials’ crushing, with

获取价格

Stone Crushers: A Technical Review on Significant Part of

2022年5月14日 Impact crushers are most commonly used in stone quarrying industry for making fine-grained stones used in road and building materials. The impact crusher as shown in Fig. 6 feed the material into the crushing chamber where a rotating disc containing hammer is working. The rotating action of the hammer apply heavy blow over the feed

获取价格

Products -

Tertiary Impact Crusher HTI. Designed specifically for the Recycling and Aggregates industries, the modular HTI series of Tertiary Impactors was designed for the economic tertiary crushing of hard rock. Compound Impact Crusher HPC.

获取价格

Types of Crushers: What You Need to Know - Machinery Partner

Roller crusher diagram Hammer mills and impact crushers. One of the most versatile crushers available, hammer mills and impactors can be primary, secondary, and tertiary crushers. Hammer mill crushers use continuous hammer blows to shatter and disintegrate material. They are typically horizontal rotating in an enclosed cylinder casing.

获取价格

Crushing 101 – Different types of crushers for distinctive needs

2020年12月17日 These different types of impact crushers share the crushing principle, impact, to reduce the material to smaller sizes, but features, capacities and optimal applications are far from each other. Horizontal shaft impact crushers are used in primary, secondary or tertiary crushing stage.

获取价格

CRUSHERS - mekaglobal

TERTIARY IMPACT CRUSHERS Designed for crushing soft and medium-hard materials with close grain distribution and good cubical shape ratios, tertiary impact crushers are an excellent solution in the production of fine aggregates for concrete and asphalt applications. Adjustable and interchangeable breaker plates enable grinding up to 50 percent

获取价格

Types of Rock Crushers Quarry Crushing Equipment Kemper

Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing equipment types, though there can be overlap between primary and secondary crushers as far as suitable types. 2. Secondary Crushing.

获取价格

Understanding the Different Types of Crushers Agg-Net

2018年9月10日 Cone crushers are used in secondary and tertiary roles as an alternative to impact crushers when product shape is an important requirement but the proportion of fines produced needs to be minimized. Even though the reduction in fines produced may only be a few percentage points, this could represent a significant amount of material in a

获取价格

Crushing 101 – Different types of crushers for distinctive needs

2020年12月17日 These different types of impact crushers share the crushing principle, impact, to reduce the material to smaller sizes, but features, capacities and optimal applications are far from each other. Horizontal shaft impact crushers are used in primary, secondary or tertiary crushing stage.

获取价格

CRUSHERS - mekaglobal

TERTIARY IMPACT CRUSHERS Designed for crushing soft and medium-hard materials with close grain distribution and good cubical shape ratios, tertiary impact crushers are an excellent solution in the production of fine aggregates for concrete and asphalt applications. Adjustable and interchangeable breaker plates enable grinding up to 50 percent

获取价格

Types of Rock Crushers Quarry Crushing Equipment Kemper

Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing equipment types, though there can be overlap between primary and secondary crushers as far as suitable types. 2. Secondary Crushing.

获取价格

Understanding the Different Types of Crushers Agg-Net

2018年9月10日 Cone crushers are used in secondary and tertiary roles as an alternative to impact crushers when product shape is an important requirement but the proportion of fines produced needs to be minimized. Even though the reduction in fines produced may only be a few percentage points, this could represent a significant amount of material in a

获取价格

Horizontal Crushers -

A Horizontal Impact Roll Crusher mainly consists of the same main components as the Feeder Breaker. Apart from the fact that the cross section of the Chain Feeder installed in a Horizontal Impact Roll Crusher is of a different design, the description is similar to the Chain Feeder installed in the Feeder Breaker.

获取价格

What is the difference between Impact Crusher and Cone Crusher?

Impact crushers may be used as a primary, secondary, or tertiary crusher depending on the producer’s final-product-size needs. These crushers are available in stationary, track and mobile designs. Another industry usage is slag, specifically blast furnace slag, which is less abrasive than steel furnace slag and can be broken down if processed ...

获取价格

Portable Impact Crushers - MEKA Concrete Plants

Portable Tertiary Impact Crushers Portable Tertiary Impact Crushers are wheel-mounted rock crushing machines, engineered for tertiary crushing applications. Equipped with a horizontal shaft impact crusher and a feed hopper with belt feeder, it is designed especially for processing soft and medium-hard materials, such as limestone and recycled materials,

获取价格

Crushers - All crusher types for your reduction needs - Metso

Horizontal shaft impact (HSI) crushers are used in primary, secondary or tertiary crushing stage. HSI crushers reduce the feed material by highly intensive impacts originating in the quick rotational movement of hammers or bars fixed to the rotor. The particles produced are then further fragmentated inside the crusher as they collide against ...

获取价格

® NP Series™ Horizontal shaft impact (HSI) crushers

® NP Series™ HSI crushers for secondary and tertiary crushing ® NP13, NP15 NP20 Impact crushers. NP13, NP15 and NP 20 impact crushers provide significant improvements for your productivity, safety, and uptime. More throughput, less recirculation The NP13, NP15 and NP20 impact crushers have

获取价格

Crushers and Their Types – IspatGuru

2015年4月3日 Similarly the output of secondary crusher is fed to the tertiary crusher which reduces the material size further. Some of the materials may pass through four or more of the crushing stages before it is reduced to the desired size. ... Impact crusher. Impact crushers make use of impact rather than compression to crush material. The

获取价格

. Crushing, Screening, Feeding.

Comprehensive stock analysis and inventory based on operational requirements. Availability of service personnel and parts required for each shutdown. Retrofitting and refurbishment of parts to extend machine service life. works in collaboration with its customers to improve process efficiencies and reduce waste.

获取价格

Impact Crushers - Parker Plant

The Kubitizer is the genuine Parker fixed hammer impact crusher for the production of high quality, high strength cubical shaped aggregates in secondary or tertiary, low abrasion applications. No shear or compressive crushing action takes place and every stone is broken by impact forces at its weakest point to provide an exceptionally strong ...

获取价格

Crushing and Screening Handbook - AusIMM

Cone crushers – capacities available to suit all secondary, tertiary or quarternary crushing ap-plications. High performance technology. Impact crushers – primary and secondary machines for soft and medium-hard materials. High reduction ratios. Can eliminate need for a tertiary crushing stage. Spare and wear parts – genuine parts always

获取价格

Products Hazemag North America

Material Testing. Our material testing facility helps you create a solid foundation of valuable information. We offer a comprehensive test plan, tailored specifically to your process goals and project needs. Discover the complete line of Hazemag products. Hazemag has the solutions for any application.

获取价格