مسكن

>

what are the types of stone crushers

مسكن

>

what are the types of stone crushers

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

what are the types of stone crushers

Types of Crushers: What You Need to Know - Machinery Partner

What Is A Crusher?Brief History of CrushersBasic Ways to Reduce Material SizeWhat Are The Different Kinds of Crushers?Primary Crushing EquipmentSecondary Crushing EquipmentTertiary Crushing Equipment and BeyondWhat Is The Difference Between A Cone Crusher and Gyratory Crusher?Let Us Be Your Machinery PartnerThere are lots of different kinds of crushers from jaw crushers to impactors and cone crushers. Crushing is an versatile process and the kind of crusher you need depends on the 'stage' of crushing. The three main stages of crushing are primary, secondary, and tertiary - all of which have their own unique benefits. Primary crushing involves using a ...

7 Types of Stone Crusher and How to Choose the Best?

Types of Rock Crushers Quarry Crushing Equipment Kemper

Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing equipment types, though there can be overlap between

获取价格

7 Different Types of Stone Crushers: A Comprehensive Guide

2023年7月28日 1. Jaw Crushers. Source: . Initiating our exploration, the first stone crusher we encounter is the jaw crusher. This type of machine boasts a simplistic yet highly effective design, employing two jaws – one stationary and the other mobile – to accomplish the task of crushing. As the mobile jaw exerts force, the material lodged ...

获取价格

Types of Crushers: What You Need to Know - Machinery Partner

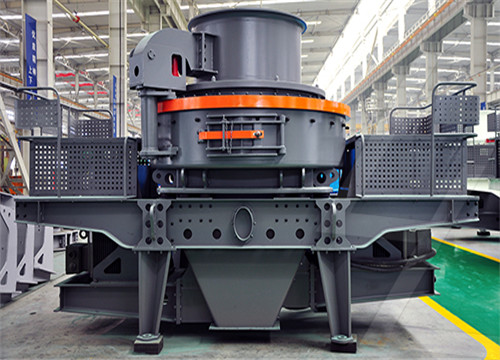

Cone crushers. Cone crushers are one of the main choices for secondary crushing. A cone crusher is a powerful machine that is used in large-scale industries for crushing various types of materials into smaller sizes. It works by applying pressure onto the material and squeezing it against a rotating mantle to create compression and force.

获取价格

Crushers - All crusher types for your reduction needs - Metso

There are two basic types of jaw crushers: single toggle and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation causes, along with the toggle plate, a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of ...

获取价格

Types of Rock Crushers Quarry Crushing Equipment Kemper

Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing equipment types, though there can be overlap between primary and secondary crushers as far as suitable types. 2. Secondary Crushing.

获取价格

What Are the Differences Between The 7 Types of Crushers?

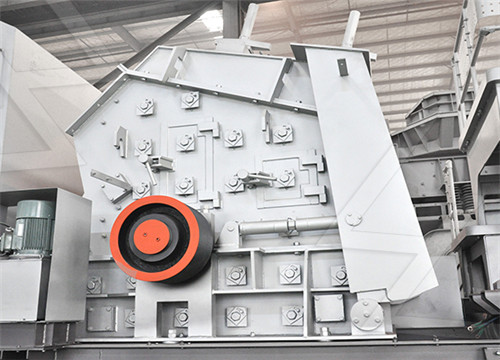

2023年2月15日 Horizontal shaft impact crusher (HSI) VS cone crusher. Horizontal shaft impact crusher adopts impact force created by high-speed rotating hammer to strike and throw material. Then the crushed material will hit aprons again in the crushing chamber, which is "stone on stone" crushing way.

获取价格

Crushing 101 – Different types of crushers for distinctive needs

2020年12月17日 Jaw crushers can be divided into two basic types, single and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation, along with the toggle plate, causes a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top

获取价格

7 Types of Stone Crusher and How to Choose the Best?

2021年9月23日 7. Roller Crusher. The work of the roller crusher is continuous. The stone is located between two parallel cylindrical rollers that move toward each other. The friction force between the stone and the roller bites the stone into

获取价格

Different Types of Stone Crusher Machines - AGICO

2023年2月22日 Primary Jaw Crusher: This type of jaw crusher is used for the first stage of crushing large and hard stones. It is designed to handle high capacities and has a large feed opening. Secondary Jaw Crusher: Secondary jaw crushers are used for the second stage of crushing. They have a smaller size and are designed to handle medium-hard to

获取价格

The Complete Guide to Crushed Stone and Gravel - Gra-Rock

2019年11月11日 Crushed stone often has an angular and jagged edge because of the crushing process. Gravel, on the other hand, typically has a very smooth texture and surface because of the natural weathering and wear of being exposed to running water. Unlike crushed stone, gravel is usually sold and used in its natural state.

获取价格

Types of Stone Crushers Machine - Mineral Processing

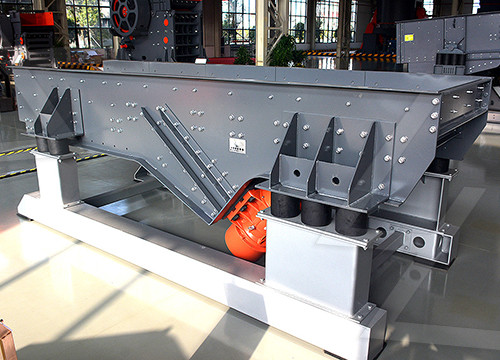

2024年1月11日 The types of stone crushers are widely used in building materials, ore crushing, railways, highways, energy, transportation, energy, cement, mining, chemical and other industries for medium and fine materials. Cone Crusher. Cone crusher is an advanced hydraulic crusher with high power, large crushing ratio, and high productivity.

获取价格

The Complete Guide to Primary Crushing, Secondary Crushing,

2023年2月28日 Each stage uses different types of crushers and has distinct advantages and disadvantages. This article provides a comprehensive guide to primary, secondary, and tertiary crushing. ... Primary crushing is commonly used in the aggregates industry for producing crushed stone and gravel. It is also used in the mining industry for processing

获取价格

Crushers and Their Types – IspatGuru

2015年4月3日 Crushers are normally low speed machines that are designed for breaking large lumps of ores and stones, even aving a size with a diameter of over one and half meter. The purpose of crusher is to reduce the size of the materials for making them usable in construction or industrial use, or for extraction of valuable minerals trapped within a ore ...

获取价格

Understanding the Different Types of Crushers Agg-Net

2018年9月10日 Impact crushers. An impact crusher uses mass and velocity to break down feed material. First, the feed material is reduced as it enters the crusher and makes contact with the rotating blow bars or hammers in the rotor. Secondary breakage then occurs as the material is accelerated into the stationary aprons or breaker plates.

获取价格

What Is The Manufacturing Process Of Stone Crusher?

The process of stone crushing involves several stages, each with specific objectives. The first step is feeding the raw materials into the stone crusher, which can be done by hand or using loaders. The materials are then transported to the crushing chambers, where they undergo crushing to reduce their size. The crushing process usually involves ...

获取价格